folding bed rail

A folding and guardrail technology, applied in children's beds, children's furniture, household appliances, etc., can solve the problems of inconvenient operation, rolling and falling, troublesome storage and storage, etc., and achieve the effect of simple structure design, stable and reliable use, and convenient storage and storage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

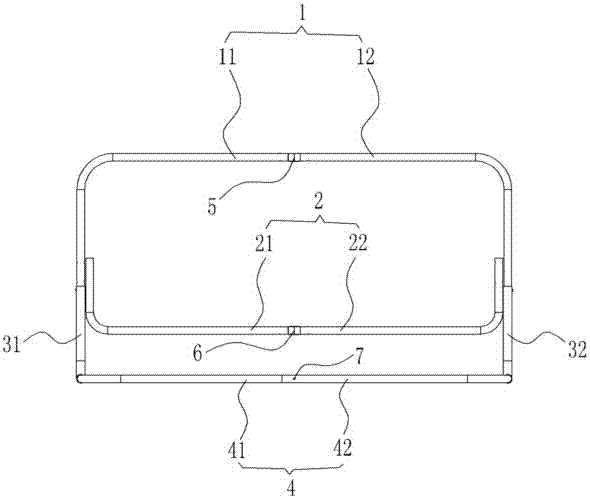

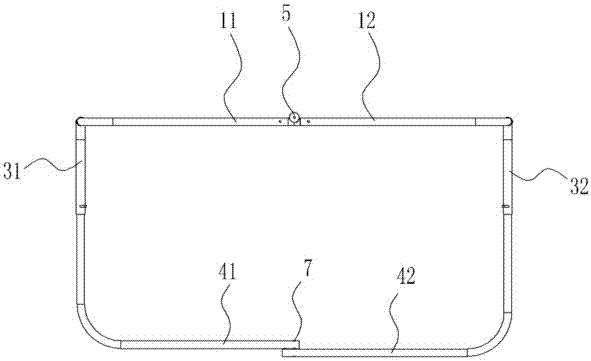

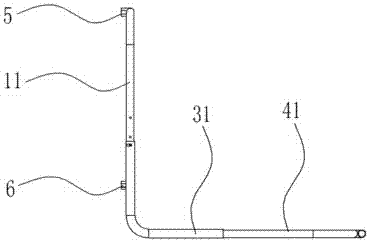

[0027] Such as Figure 1~Figure 8 As shown, 1. ejector rod, 11. left ejector rod, 12. right ejector rod, 2. middle rod, 21. left middle rod, 22. right middle rod, 31. left connecting rod, 32. right connecting rod, 4 .Foot lever, 41. Left foot lever, 42. Right foot lever, 5. Upper turning point, 6. Middle turning point, 7. Lower turning point, 8. Rotating shaft, 9. Positioning block, 10. Guide groove.

[0028] Folding bed rails such as Figure 1~Figure 4 As shown, it relates to a baby article installed on the side of the bed to prevent babies from rolling and falling while sleeping on the bed. and other components, and these rods are usually connected to each other by circular metal tubes to form a frame structure. This embodiment is described according to the use state of the bed guardrail after installation as the internal and external positional re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com