Glue joint structural part manufacturing tool adapting to different sizes

A technology that adapts to different structural parts, applied in the field of making tooling for glued structural parts that can adapt to different sizes, can solve the problems of increasing the production cost of the glued structure, high production, storage, management, and maintenance costs, and achieve diversification. , Reduce tooling costs and achieve the effect of size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

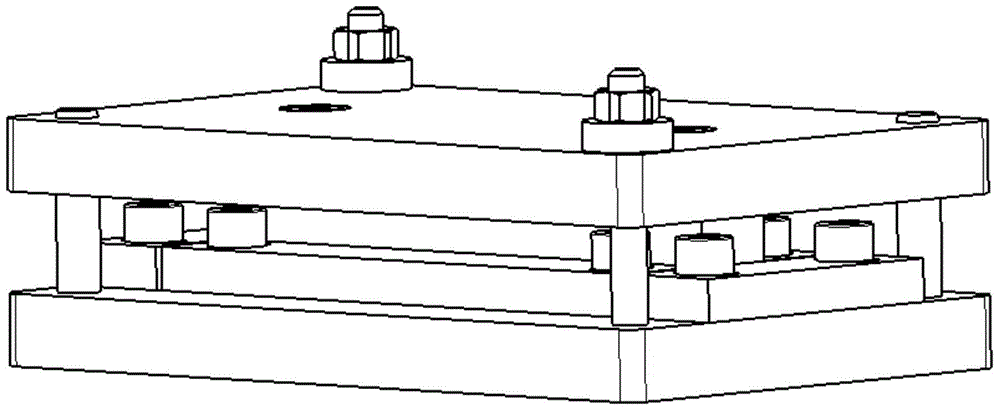

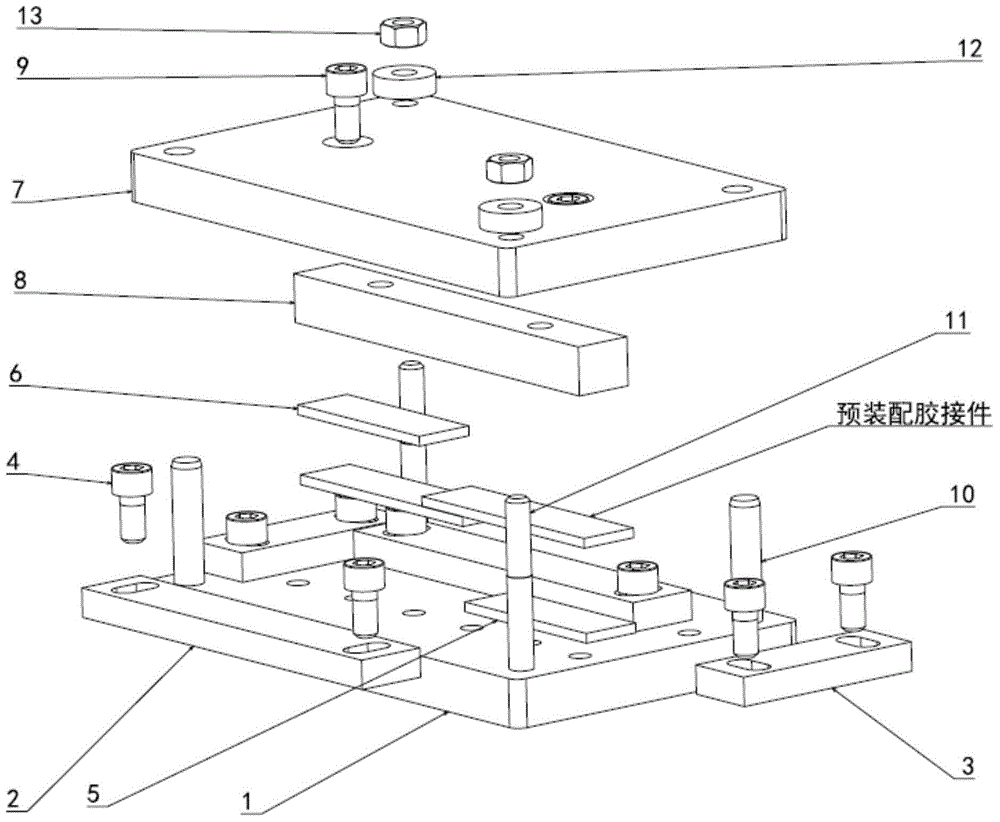

[0028] The structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0030] A manufacturing tooling for glued structural parts adaptable to different sizes, characterized in that:

[0031] The tooling comprises a punch connected by guide pins 10, a punch that can move up and down, a lower die, a pressure applying device and a heating device;

[0032] The punch is made up of a rectangular cover plate 7 and briquetting blocks 8 of different geometric sizes. There are round holes on the cover plate 7 and threaded holes at the corresponding positions of the briquetting blocks 8. The cover plate 7 and the briquetting blocks 8 are connected by screws 9 to form a lower raised punch;

[0033] Described die is made up of rectangular bottom plate 1 and is installed on the bottom plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com