Discharge device roller structure

A discharge drum and drum technology, applied in the field of discharge drum, can solve the problems of affecting the quality of finished products and uneven raw and cooked clinker, and achieve the effect of improving the uniformity of discharge, improving the quality of finished products, and overcoming the side wall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

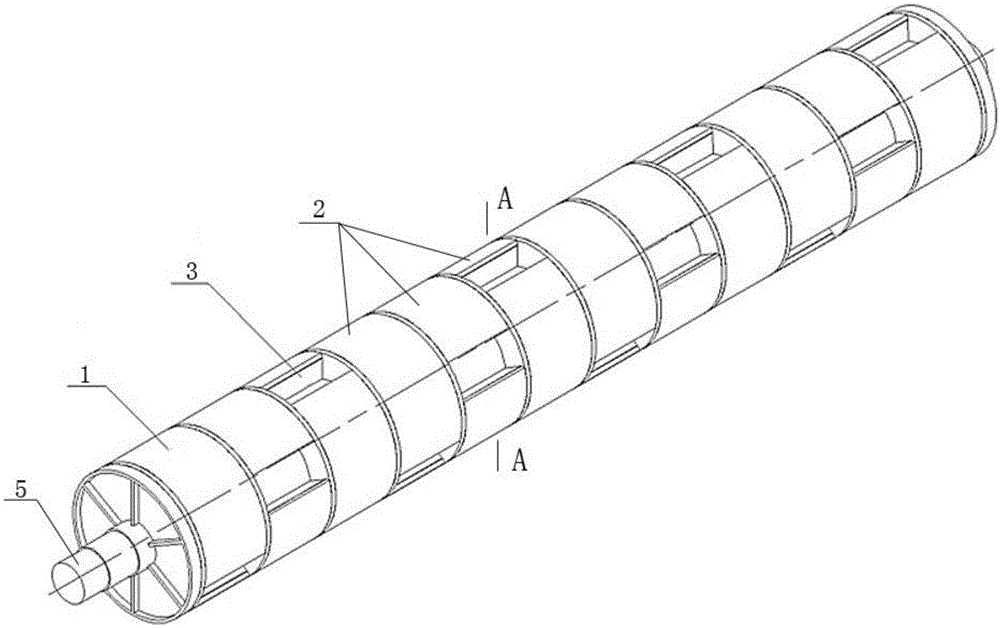

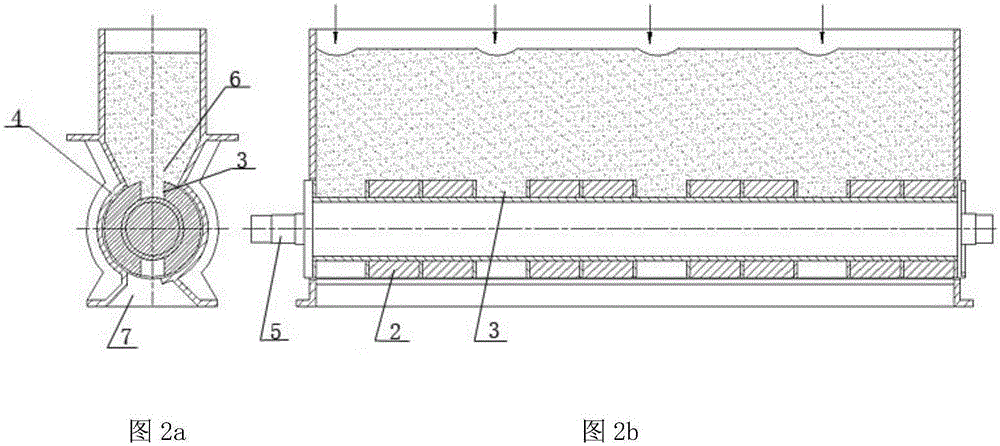

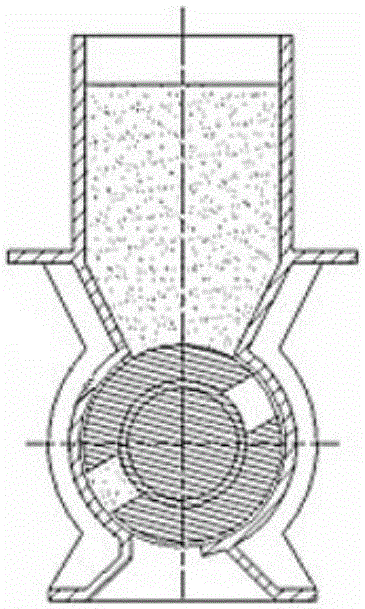

[0020] See figure 1 , is a structural schematic diagram of the present invention, a drum structure of a discharge device of the present invention, including a discharge drum 1, and the discharge drum 1 is composed of a plurality of single row drums 2 arranged axially on a rotating shaft 5, each single row Several hoppers 3 are evenly arranged on the drum 2 along the circumferential direction, and each single-row drum 2 is arranged alternately along the same direction; that is, the hoppers 3 on the entire discharge drum 1 are arranged in multiple parallel helical lines along the axial direction.

[0021] The single-row rollers 2 are sequentially arranged at the same staggered angle.

[0022] The hoppers 3 have the same shape and size; the angle between the centerlines of adjacent hoppers 3 on the same single-row drum 2 is larger than the opening a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com