A kind of wear-resistant steel bar and its production method

A production method and wear-resistant steel technology, applied in furnaces, heat treatment equipment, heat treatment furnaces, etc., can solve the problems of heavy labor burden on workers, reduce the service life of equipment, waste of resources, etc., achieve uniform and stable product performance, increase service life, The effect of reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

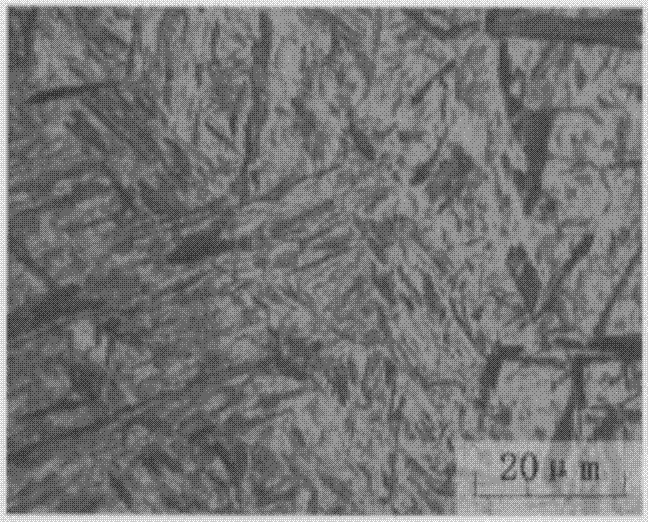

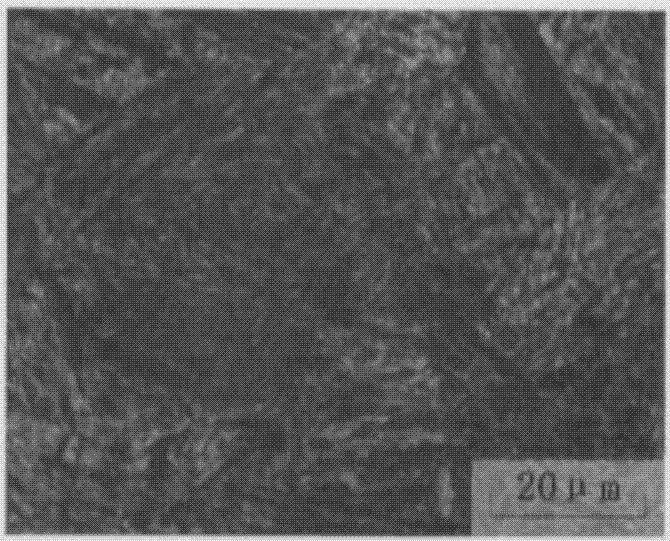

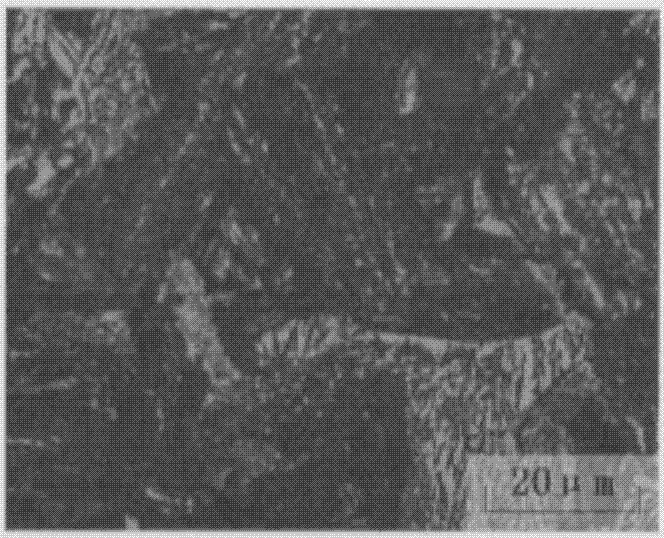

[0021] A kind of wear-resistant steel bar, which is a 42CrMo round bar with a diameter of 100mm. From the surface of the steel bar to the center, its organizational structure includes 5 layers: the first layer is a decarburized layer with a thickness of 0.2mm; the second layer is a quenched Martensitic layer. body, thickness 0.8mm; the third layer structure is tempered martensite + a small amount of bainite, thickness 16mm; the fourth layer structure is tempered martensite + gradually increasing bainite along the center, thickness 16mm; the rest are The fifth layer, its organization is bainite + acicular martensite + a very small amount of pearlite.

[0022] The wear-resistant steel rod is made from a 42CrMo round rod obtained by rolling steel through quenching and self-tempering.

[0023] Its specific production method includes the following steps: (1) Using an induction heating furnace to heat the 42CrMo round bar obtained by rolling (hot rolling) to 740±10°C and continue to...

Embodiment 2

[0028] A wear-resistant steel rod, which is a 42CrMo round rod with a diameter of 100mm. From the surface of the steel rod to the core, its structure includes 5 layers: the first layer is a decarburized layer with a thickness of 0.3mm; the second layer is a quenched Martensitic layer. body, thickness 1.0mm; the third layer structure is tempered martensite + a small amount of bainite, thickness 17mm; the fourth layer structure is tempered martensite + gradually increasing bainite along the center, thickness 17mm; the rest are The fifth layer, its organization is bainite + acicular martensite + a very small amount of pearlite.

[0029] The wear-resistant steel rod is made from a 42CrMo round rod obtained by rolling steel through quenching and self-tempering.

[0030] Its specific production method includes the following steps: (1) use induction heating furnace to heat 42CrMo round bar to 740±10°C and continue to heat up to the quenching temperature within 3 minutes, and the quen...

Embodiment 3

[0032] A wear-resistant steel rod, which is a 42CrMo round rod with a diameter of 100mm. From the surface of the steel rod to the core, its structure includes 5 layers: the first layer is a decarburized layer with a thickness of 0.3mm; the second layer is a quenched Martensitic layer. body, thickness 0.9mm; the third layer structure is tempered martensite + a small amount of bainite, thickness 17mm; the fourth layer structure is tempered martensite + gradually increasing bainite along the center, thickness 16mm; the rest are The fifth layer, its organization is bainite + acicular martensite + a very small amount of pearlite.

[0033] The wear-resistant steel rod is made from a 42CrMo round rod obtained by rolling steel through quenching and self-tempering.

[0034] Its specific production method includes the following steps: (1) use induction heating furnace to heat 42CrMo round bar to 740±10°C and continue to heat up to quenching temperature in 4min, said quenching temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com