Method and structure for preventing rock-fill dam crest road from cracking

A rockfill dam and pavement structure technology, applied to roads, dams, roads, etc., can solve problems such as dam crest pavement cracking, and achieve the effects of avoiding cracking, obvious economic advantages, and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

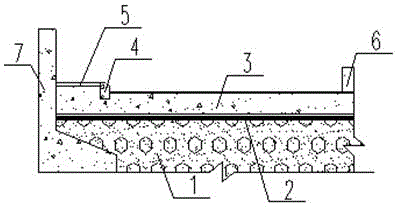

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but not as a limitation to the present invention.

[0018] Embodiments of the present invention: a method for preventing cracking of a rockfill dam crest road, mainly carried out according to the following steps during construction:

[0019] (1) Complete transition material filling and rolling on the upper part of the dam body rockfill;

[0020] (2) After the settlement value and rate of the dam body meet the engineering requirements, start pouring the upstream wave wall;

[0021] (3) Level the surface layer of the transition material at the end of the dam crest, and lay reinforcement mesh and reinforcement rods to ensure that the laying surface is smooth;

[0022] (4) Start the construction of pavement structure, curb stone, sidewalk and anti-collision pier.

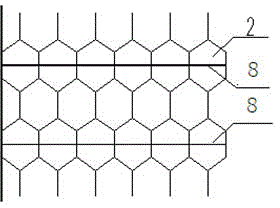

[0023] The reinforced mesh is a mesh structure, and the reinforced rods are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com