Underwater friction stitch welding quality improvement method

A friction stitch welding, quality technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., to improve welding quality, reduce or avoid cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

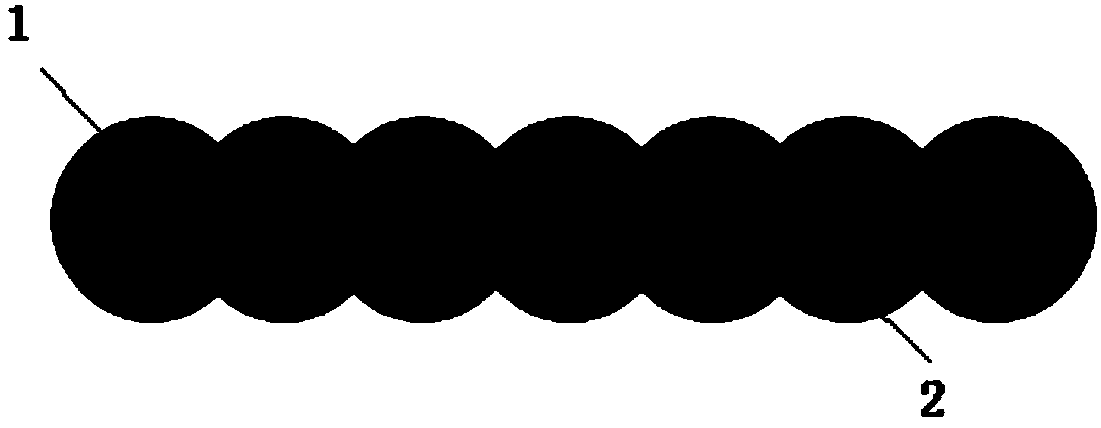

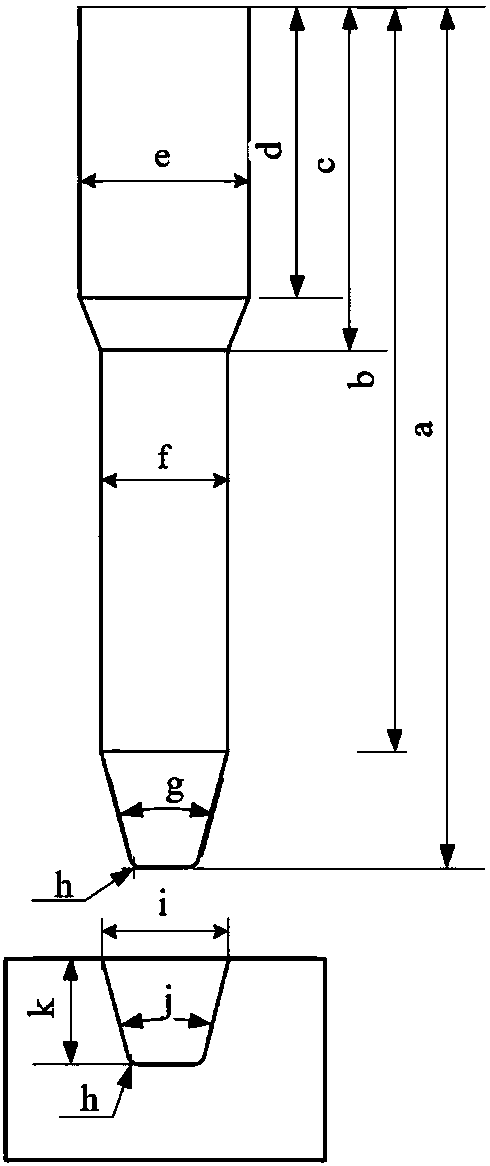

[0025] Friction stitch welding research was carried out on submerged arc welds with DH36 steel as base metal. The material of the stopper rods for the plug holes on both sides (odd-numbered welding areas) is Q345 steel, and the material of the stopper rods for the middle plug holes (even-numbered welding areas) is X65 steel. Attached Table 1 and Attached Table 2 are the main components and basic mechanical properties of DH36, submerged arc weld metal (Arc weld), Q345 steel and X65 steel. Attached Table 3 shows the process parameters of the friction stitch welding experiment. D13, D16 and D19 represent stopper rods with even hole depths of 13mm, 16mm and 19mm respectively. The specific plug hole and stopper rod structures are as follows (mm, °):

[0026] a:150, b:132, c:60, d:50, e: f: g: 19°, h: R3, i: j: 25°, k: 16

[0027] Attached Tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com