Circular tensioning connection method for insulation board clamped by double waterproof boards for tunnel

A connection method and waterproof board technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of difficult installation of insulation boards and easy collapse of insulation boards, and reduce the collapse rate of insulation boards and reduce installation and fixation. Difficulty, the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

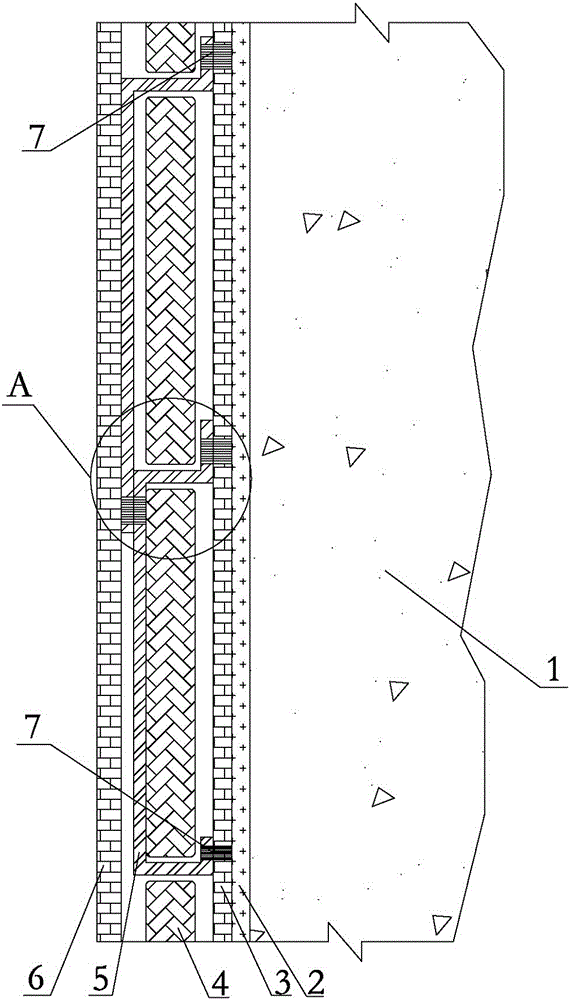

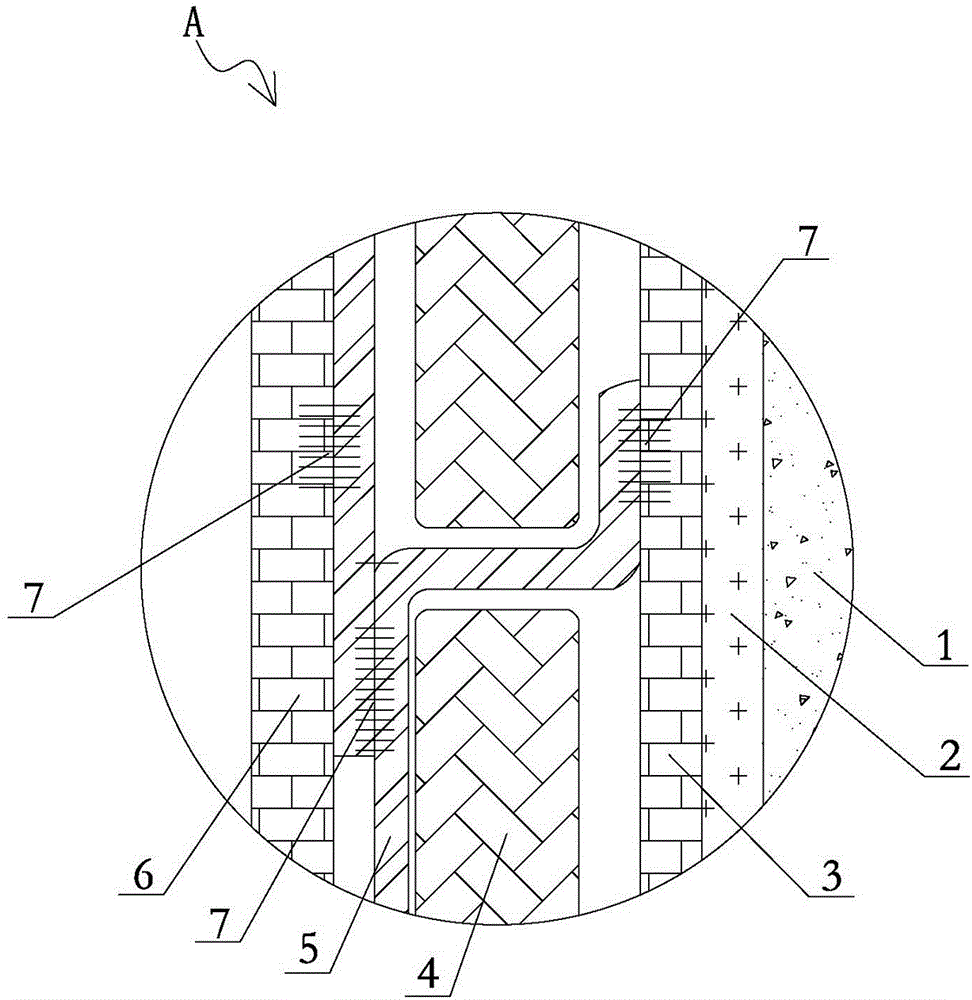

[0025] Relevant present invention is for reaching above-mentioned purpose of use and effect and the technical means adopted, presents preferred feasible embodiment, and cooperates as shown in the accompanying drawings, detailed description is as follows:

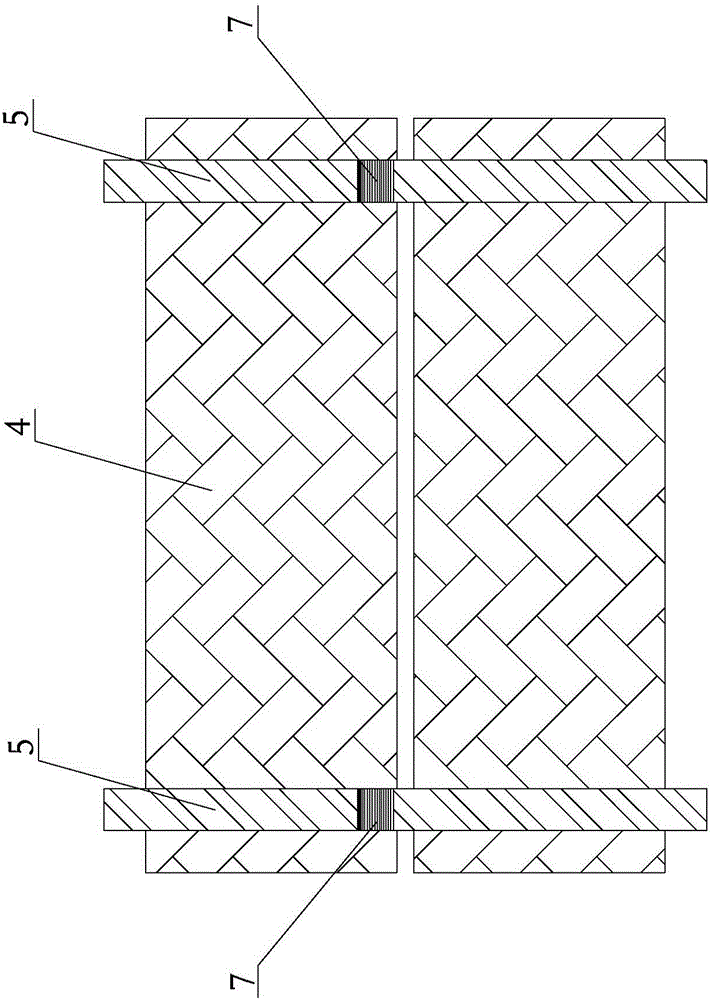

[0026] Such as Figure 1 to Figure 3 As shown, the present invention provides a method for hoop tension connection of tunnel double-layer waterproof board clip insulation board, which has the following steps:

[0027] 1) Initial support 1 surface treatment

[0028] According to the requirements of the specification, remove the bolt heads and sharp objects exposed on the surface of the initial support 1, and spray the grooves left over from the shotcrete. provide assurance.

[0029] 2) Geotextile 2 Laying

[0030] When laying, the lap length between adjacent geotextiles 2 is not less than 5cm, and there are multiple fixed points (not shown in the figure) on the geotextile 2, each fixed point is provided with a hot-melt gas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap