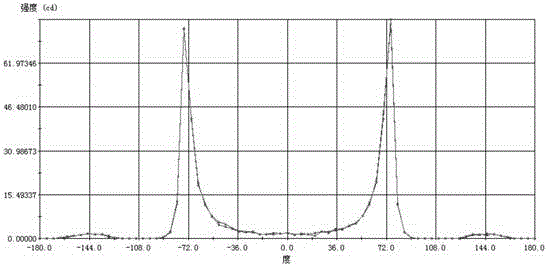

Wide-angle lens used for uniform near-field illumination

A uniform lighting and wide-angle lens technology, which is applied to the components of lighting devices, lighting devices, lighting and heating equipment, etc., can solve the problems of size limitation, attenuation, and high cost of the light output surface, so as to ensure the uniformity of illumination and increase the light output Angle, the effect of improving edge illumination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

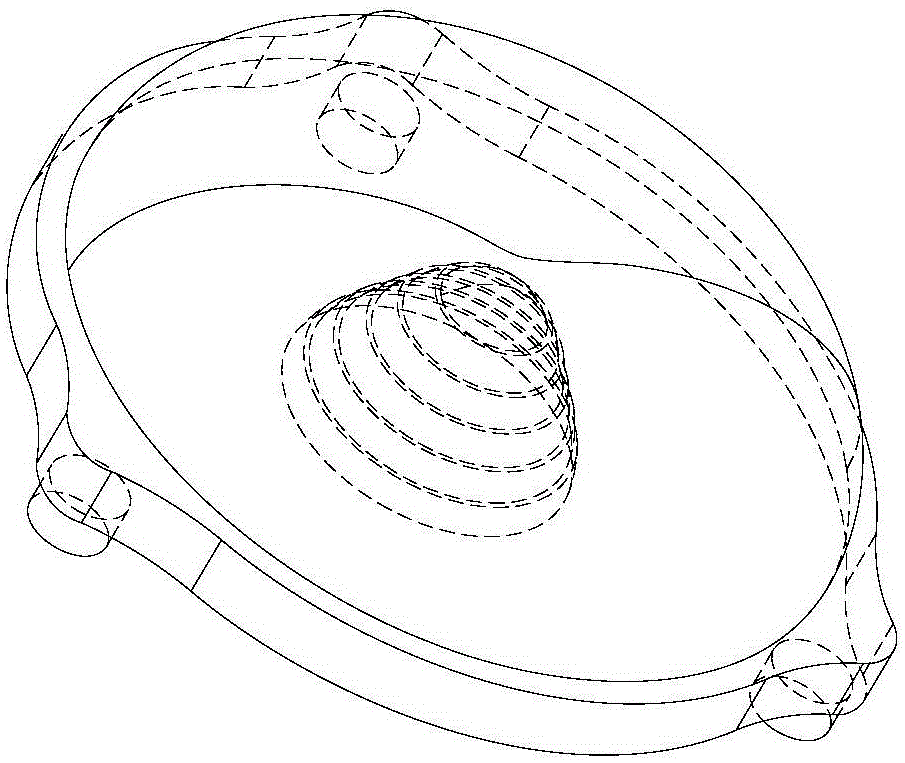

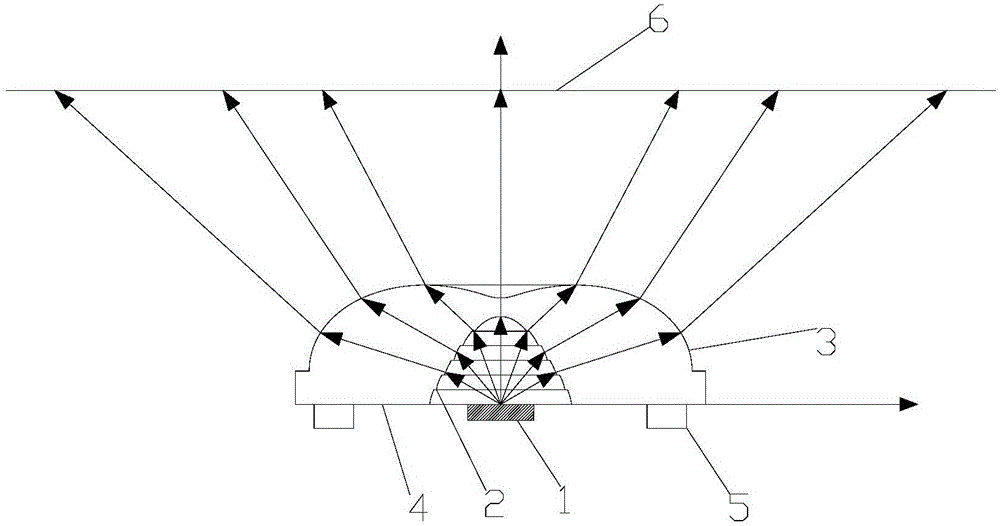

[0035] In order to further explain the technical solution of the present invention, it will be described in detail below in conjunction with the accompanying drawings.

[0036] figure 1 and figure 2 The lens shown is a wide-angle optical lens for near-field uniform illumination of the present invention, which is made of a transparent material with a refractive index of 1.45-1.6 and manufactured by injection molding. The material is not limited to polycarbonate (PC), polymethyl methacrylate (PMMA).

[0037] Such as figure 2 As shown, in this example, the wide-angle lens is rotationally symmetrical around the Z axis. The optical lens includes an inner concave surface 2 , an outer convex surface 3 , a bottom surface 4 , a positioning bracket 5 and a microstructure 7 . The light-emitting diode 1 is placed directly below the central axis of the bottom of the lens, and the light-emitting surface of the light source is flush with the bottom surface. The inner concave surface 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com