A micro-distance seepage monitoring sensor

A technology for monitoring sensors and seepage, applied to instruments, measuring devices, scientific instruments, etc., can solve the problems of not being able to detect early seepage and hidden dangers in time, and achieve the effect of improving the spatial resolution of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

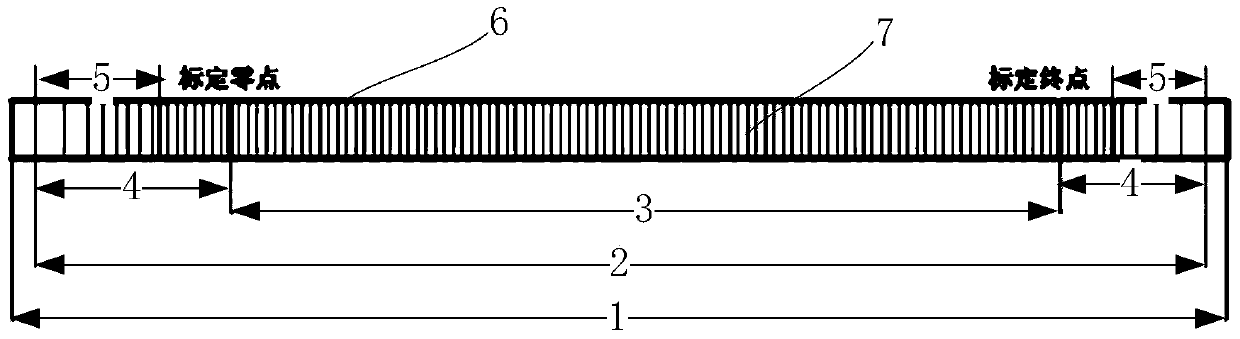

[0017] see figure 1 , The embodiment of the present invention provides a micro-distance seepage monitoring sensor including: a core rod 6, a wire and an optical fiber 7. The wire is wound on the mandrel 6 . Marking points for marking the scope of the actual measurement area 3 are also arranged on the mandrel; the calibration points include a calibration zero point and a calibration end point; the area between the calibration zero point and the calibration end point constitutes the actual measurement area 3 . The length of the non-uniform area 5 is smaller than the length of the interference area 4 . The length of the fiber zone 2 is less than the length of the core rod 6 . Mandrel 6 is cylindrical. The mandrel 6 has a smooth surface. The mandrel 6 consists of a PVC pipe. The wires include heating wires. The optical fiber 7 is wound on the wire. The radius R of the sensor is greater than 12.5mm. The length of the sensor is 1 m. The wire is evenly wound on the mandrel 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com