Anti-shedding power plug-socket unit

A power plug and anti-dropping technology, applied in circuits, electrical components, coupling devices, etc., can solve problems such as easy damage, difficult separation of plugs and sockets, etc., to achieve the effect of simple structure, reduced power safety hazards, practical and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

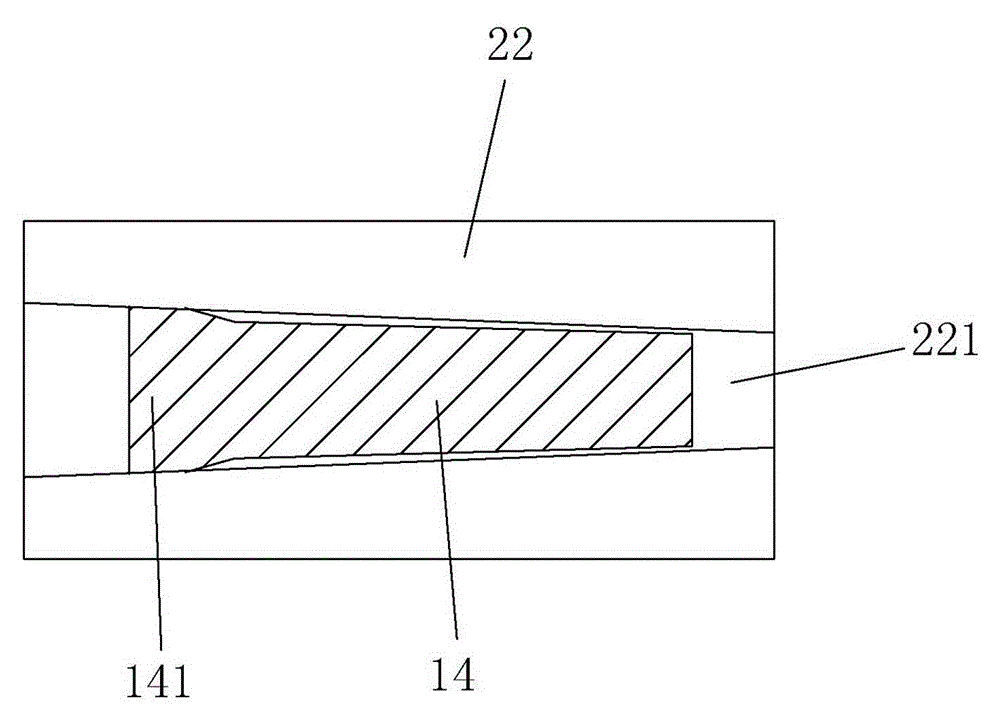

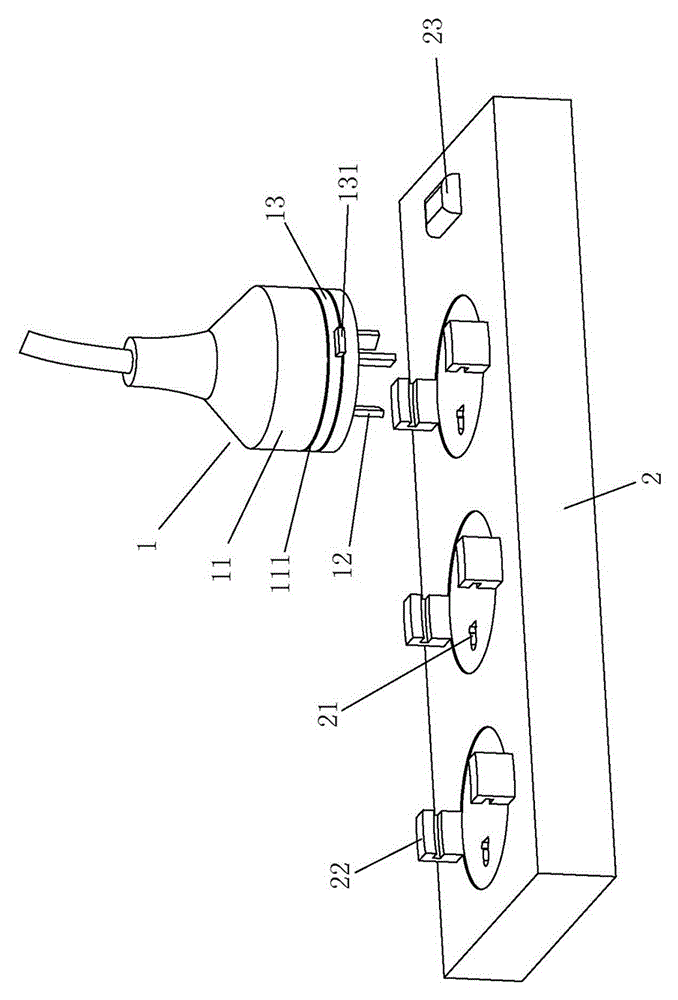

[0019] Embodiment 1: as figure 1 and figure 2 As shown, an anti-falling power plug and socket includes a plug 1 and a socket 2. The plug 1 is a two-pin plug or a three-pin plug, and includes an insulating seat 11 and an insert 12 arranged on the insulating seat 11. The insulating seat 11 is provided with A power switch, the power switch controls the contact or disconnection of the insertion piece with the wire in the insulating seat. The socket 2 is an in-line socket, one end of the socket 2 is provided with a switch button 23, and the socket 2 is provided with several sets of jack groups 21 corresponding to the insertion pieces 12, and the jack groups 21 are arranged on the socket 2 along a straight line. The socket 2 is provided with fixing seats 22 surrounding each group of jacks 21 , and the number of fixing seats 22 arranged around each group of jacks 21 is at least two, and the number of fixing seats 22 around each group of jacks 21 is evenly distributed around the cir...

Embodiment 2

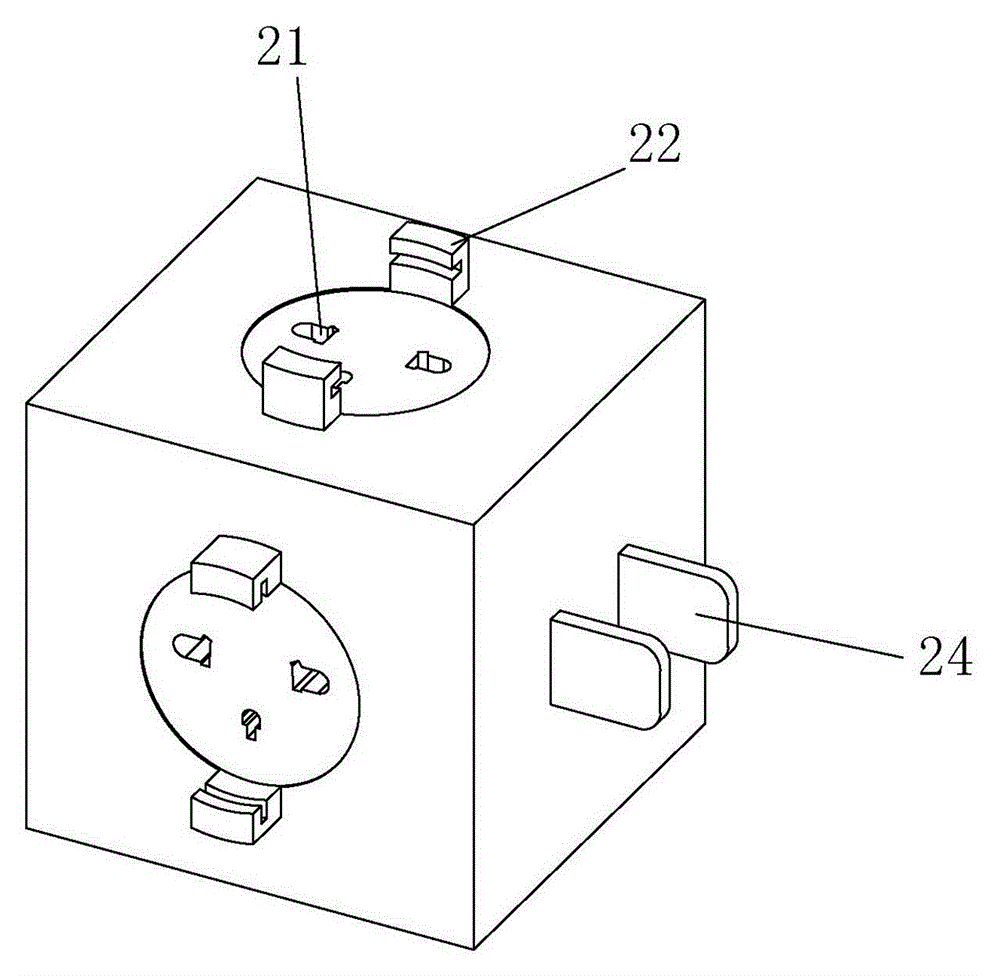

[0021] Embodiment 2: as image 3 As shown, the difference from the above embodiment is that the socket 2 is a cube structure, the four end faces of the socket 2 are provided with socket groups 21, the fifth end face of the socket 2 is provided with a conductive part 24, and the sixth end face Connecting holes matching the conductive portion 24 are provided on the top, allowing any number of sockets 2 to be connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com