Noodle basket component and continuous noodle cooking machine using same

A technology of noodle cooking machine and components, which is applied in application, food preparation, food science, etc. It can solve the problem of inconvenient water in the noodle basket, and achieve the effect of avoiding deformation and facilitating water inflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

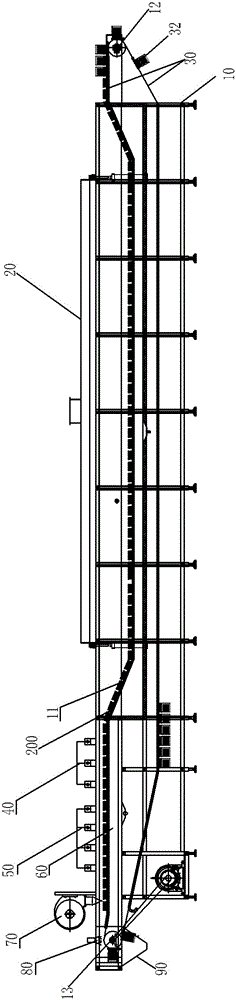

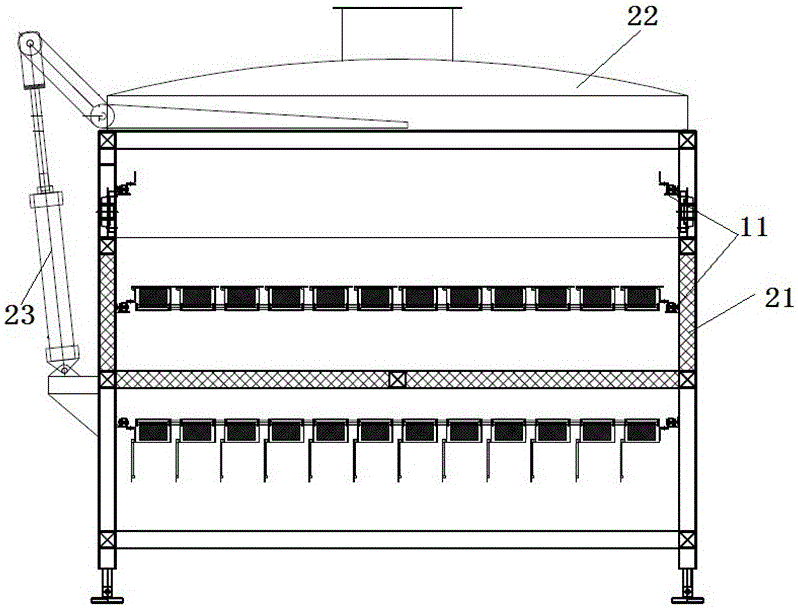

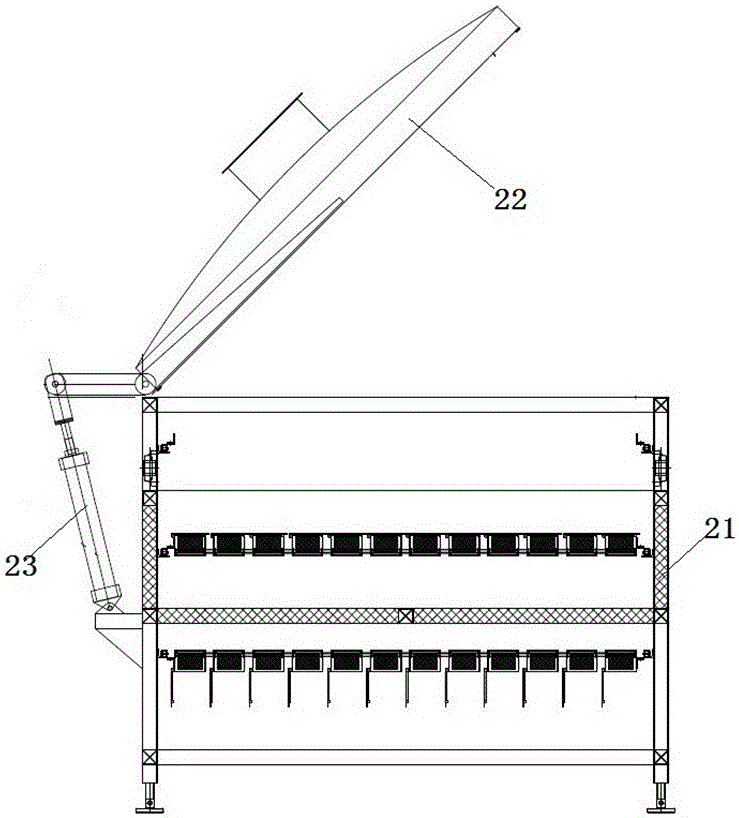

[0031] Such as Figure 1 to Figure 7 As shown, an embodiment of a continuous noodle cooker, in this embodiment, the continuous noodle cooker includes a frame 10 on which a boiling pot 20 is provided, and the frame 10 is also provided with a reciprocating through boil The conveyor chain 30 of the pot 20 is provided with a conveyor chain inlet and a conveyor chain outlet on the boiling pot. The conveyor chain 30 includes a conveyor chain 31 and a noodle basket assembly 32 fixed on the conveyor chain 31 and extending along the width direction of the conveyor chain. The noodle basket assembly 32 is provided with a plurality of noodle baskets 320 for holding noodles. With the reciprocating action of the conveying chain, the noodle box circulates in and out of the boiling pot. The boiling pot 20 here includes a pot body 21 fixed on the frame 10 and a pot lid 22 hinged on the pot body. The pot lid 22 is driven by a hydraulic drive mechanism 23 to rotate around the corresponding hinged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com