Mixed liquor continuous separation device

A separation device and mixed liquid technology, applied in the field of chemical equipment, can solve problems such as narrow application range, complex structure, impact on energy saving, emission reduction and waste reuse, and achieve the effect of increasing applicability, increasing effect and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

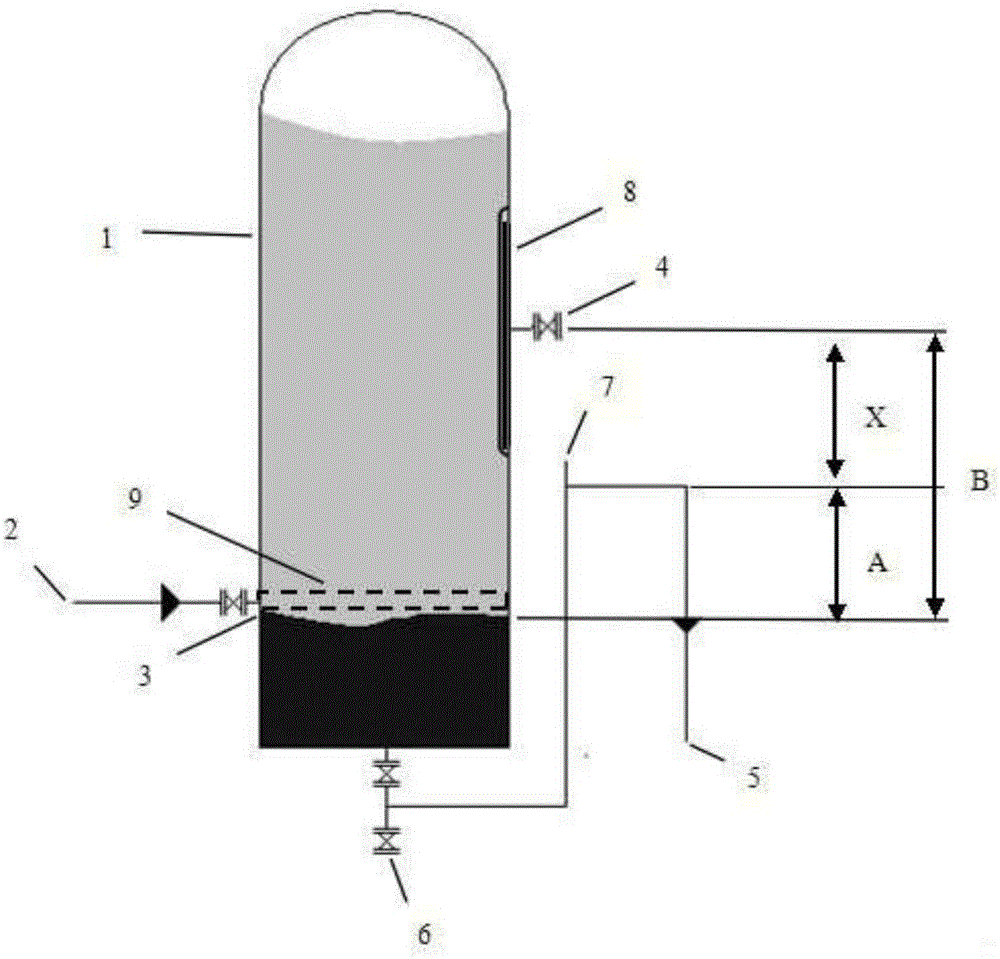

[0021] like figure 1 As shown, the device provided by the present invention comprises a mixed liquid water separation container 1, a mixed liquid inlet 2, a water separation interface 3, an organic liquid overflow port 4, an aqueous phase overflow port 5, a net discharge port 6, and a vent port 7; The interface 3 is the reference surface, the height of the organic liquid overflow port 4 is B, the height of the water phase overflow port 5 is A, and the height difference between the two is X=B-A, B*ρ 1 =A*ρ 2 , where ρ 1 is the organic phase density, ρ 2 is the density of the aqueous phase.

[0022] The device also includes a height controller 8 for the organic liquid overflow 4 .

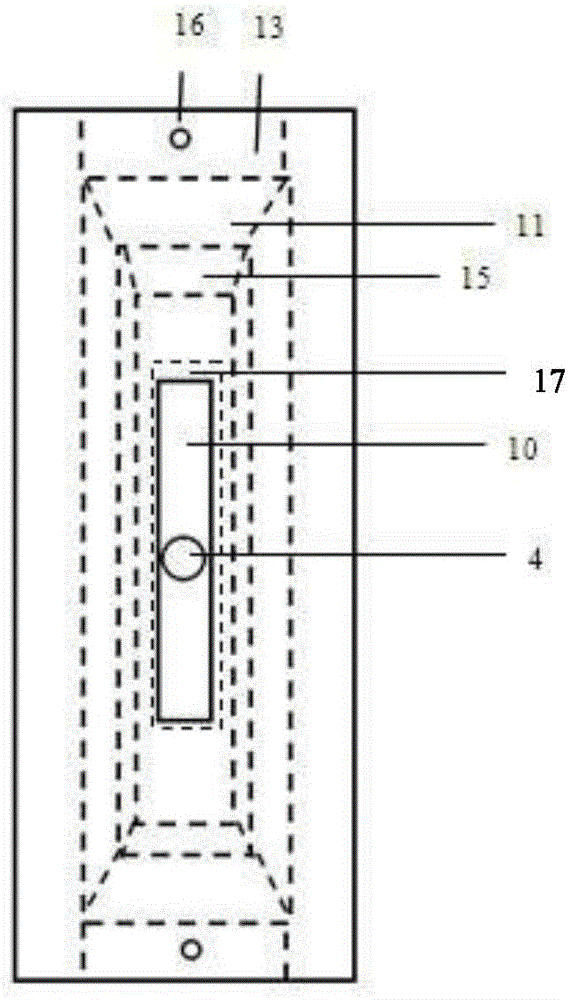

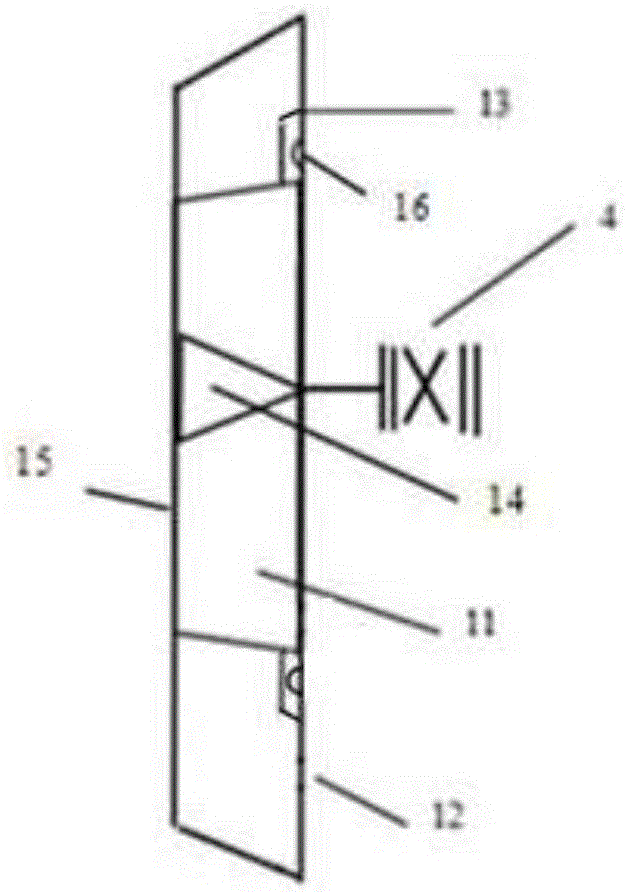

[0023] Among them, such as figure 2 and 3 The shown height controller 8 includes the outer wall 12 of the mixed liquid water separation container 1, the inner wall 15 of the mixed liquid water separation container 1, the width of the elastic piston 11 is the same as that formed by the inner an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com