Environment-friendly board polishing device

An environment-friendly, plate-based technology, applied in the direction of grinding/polishing safety devices, grinding machines, grinding/polishing equipment, etc., can solve the problems of operating environment impact, difficulty in wood chip recycling, high frequency of use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0018] The present invention will be described in detail below with reference to the accompanying drawings and examples.

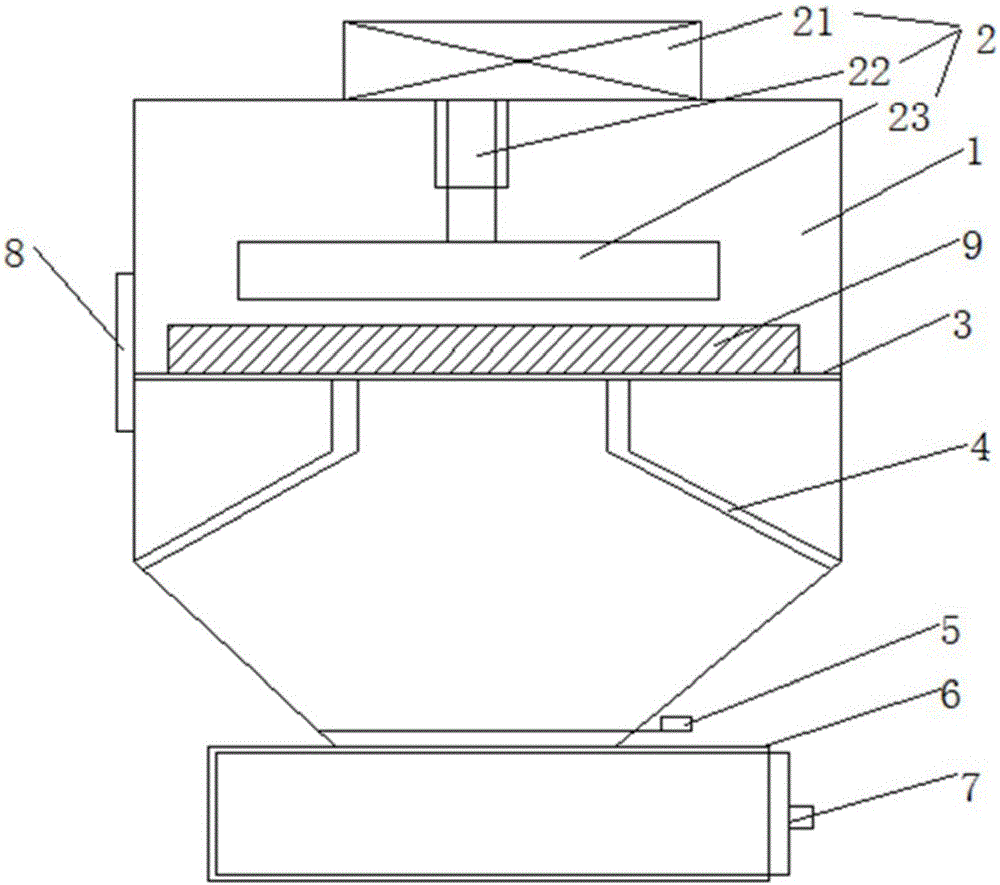

[0019] Such as figure 1 As shown, the present invention is an environment-friendly plate grinding device, including a chassis 1, a polishing assembly 2, a support frame (for supporting a plank 9 to be polished) and a sawdust collection device, and the polishing assembly 2 includes a motor 21 connected in sequence , a rotating shaft 22 (preferably, the rotating shaft is a retractable rotating shaft) and a polishing disc 23, and the support frame includes a hollowed-out horizontal support body 3 (the hollowed-out structure is convenient for the collection of wood chips after polishing) and some support ribs 4, The sawdust collection device includes a dust collection tank 6 and a dust coll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com