Full-automatic mask folding machine

A fully automatic mask technology, which is applied in packaging and other directions, can solve the problems of mask product pollution, small friction, and low density of mask materials, and achieve the effects of avoiding pollution, reducing product costs, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

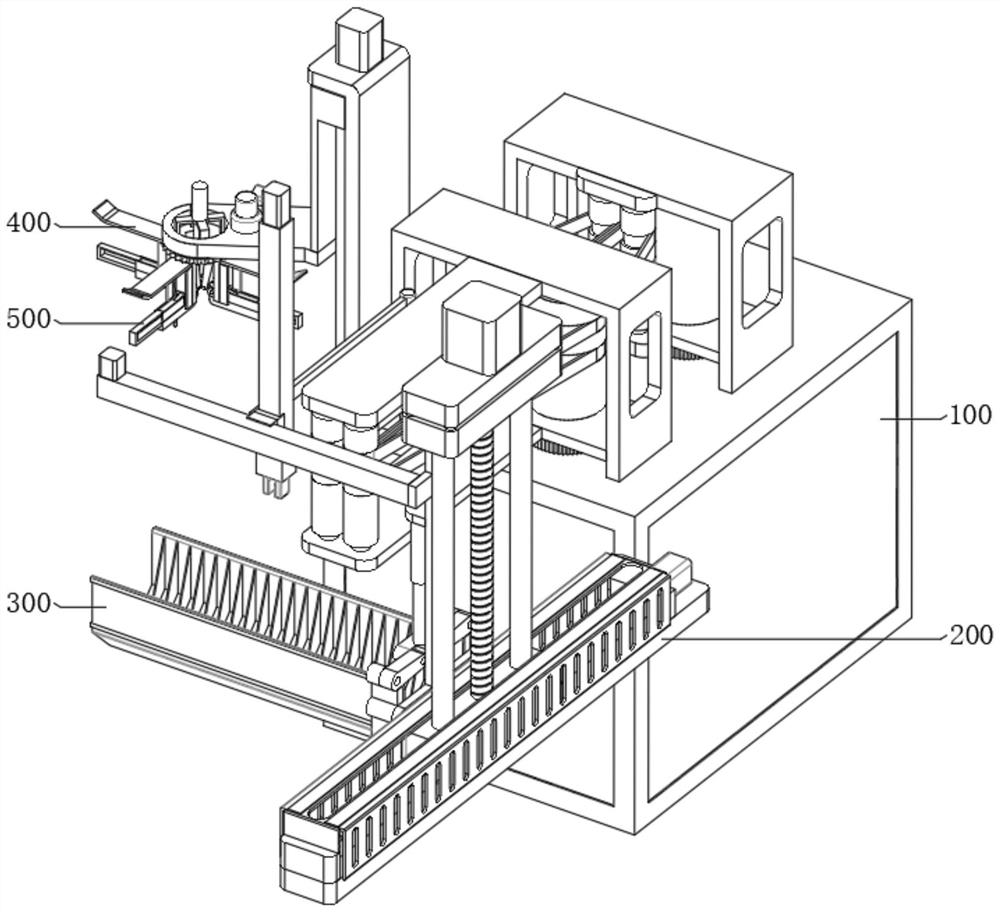

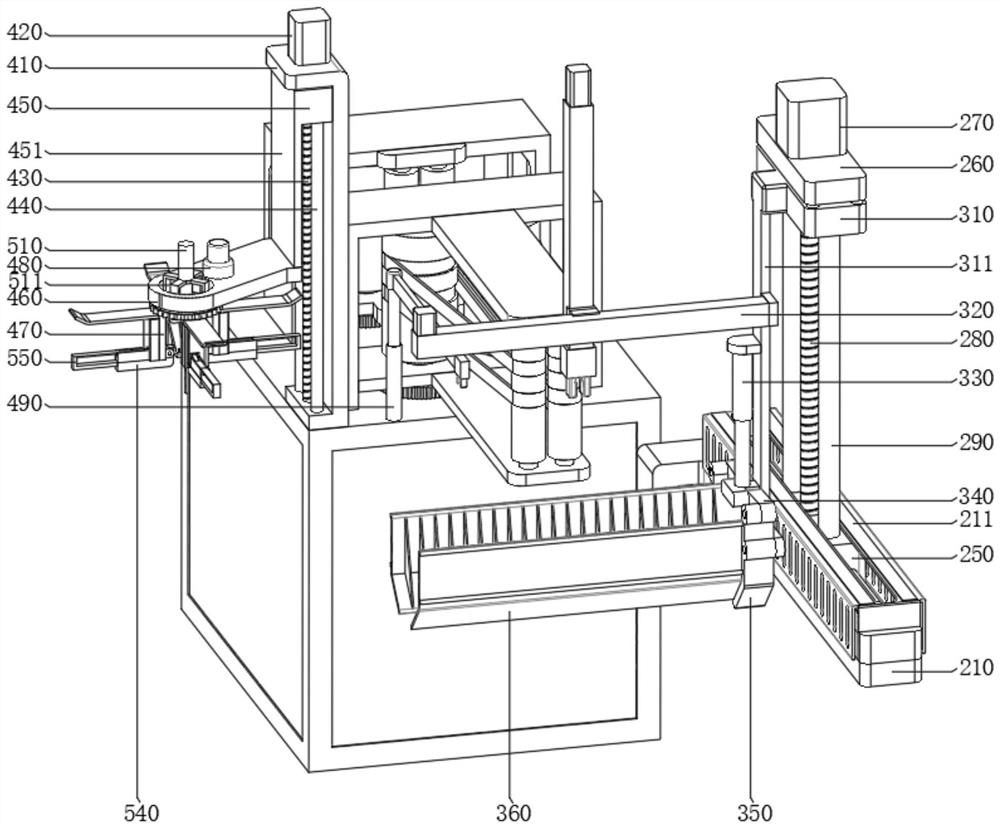

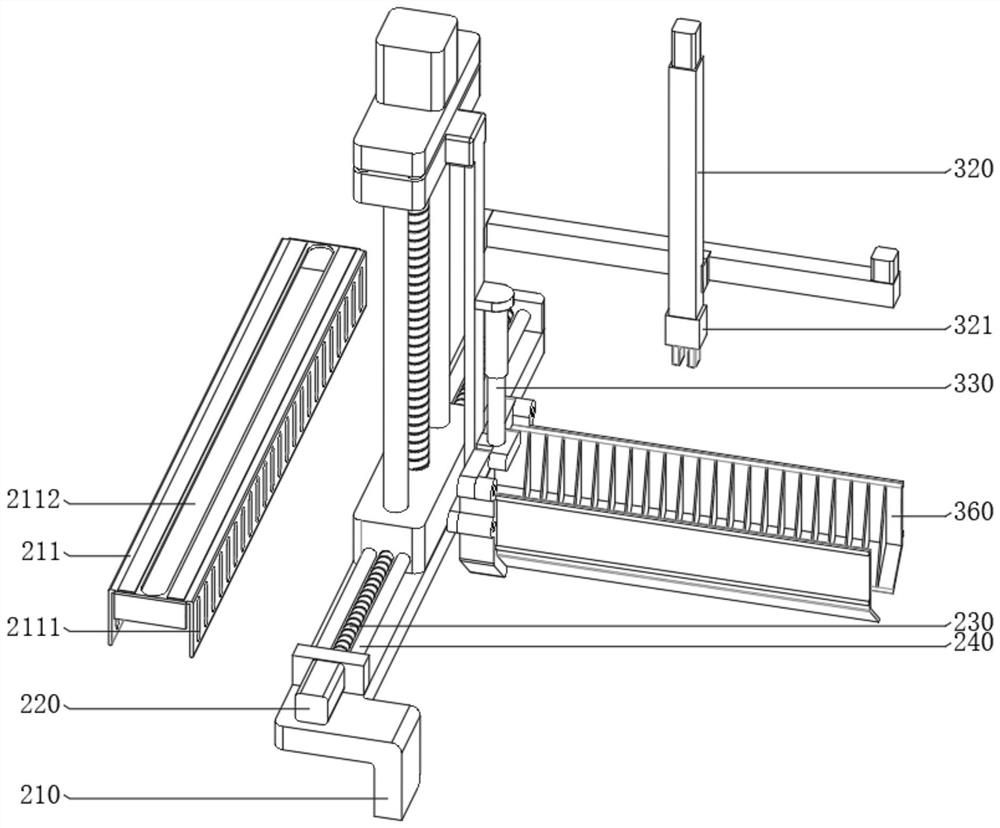

[0045] like Figure 1-Figure 12 As shown, a fully automatic folding mask machine according to the embodiment of the present application includes an automatic folding mask machine body 100, a supporting and moving mechanism 200, a mask collecting and summarizing mechanism 300, a residual material winding mechanism 400 and a telescopic support mechanism 500. The moving mechanism 200 is arranged on the output end side of the automatic folding mask machine body 100, and the mask collecting and summarizing mechanism 300 is arranged on the supporting and moving mechanism 200. The collection is stacked and neatly placed in the collection container to avoid pollution caused by hanging or scattering the finished mask products on the ground, saving manpower for sorting and arranging the finished masks. On the other side of the output end, it is convenient to rewind the residual material generated after the production of the mask, and the telescopic support mechanism 500 is arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com