Automatic packaging equipment

A technology of automatic packaging and equipment, applied in packaging, packaging under vacuum/special atmosphere, etc., can solve the problem of large equipment volume and cannot be retrofitted, and achieve the effect of automatic reconstruction, simplified equipment structure, and reduced occupied volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

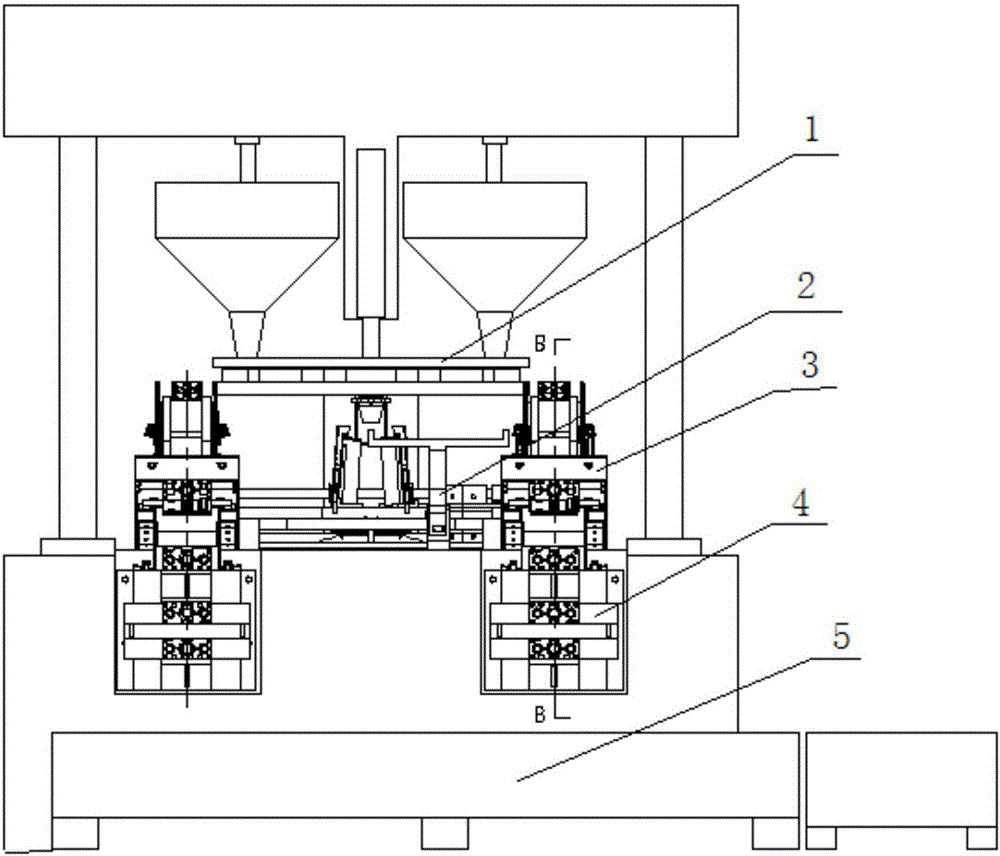

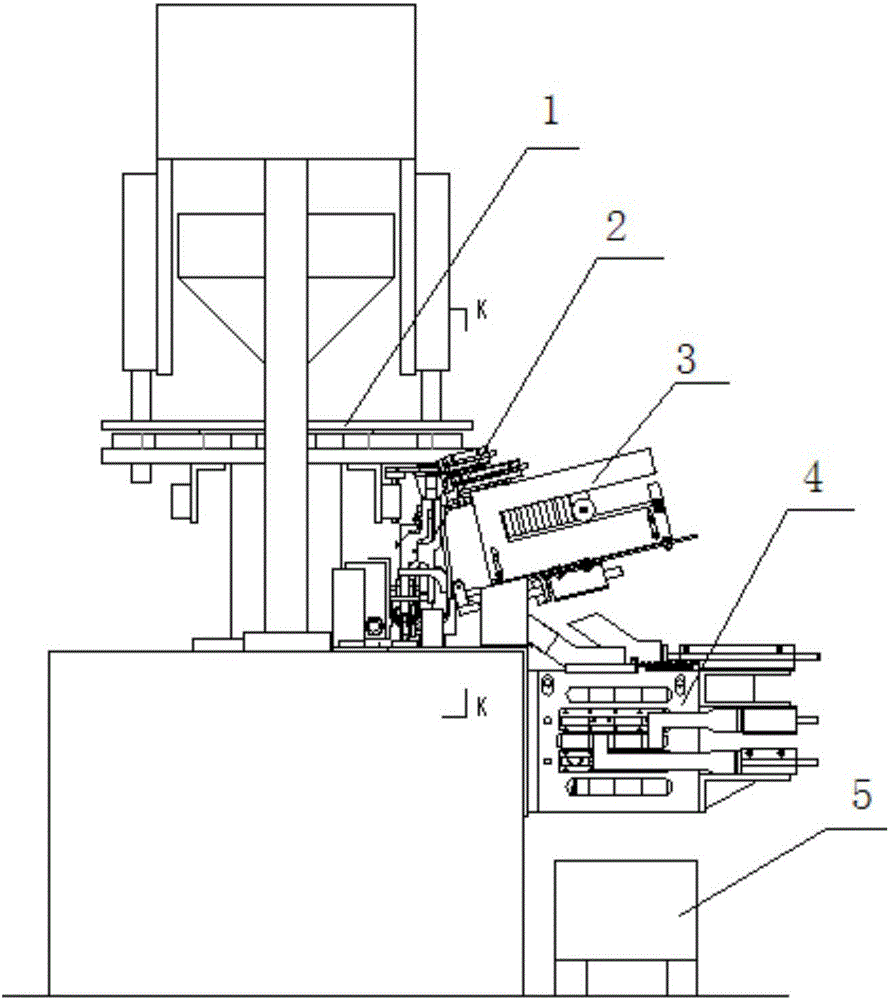

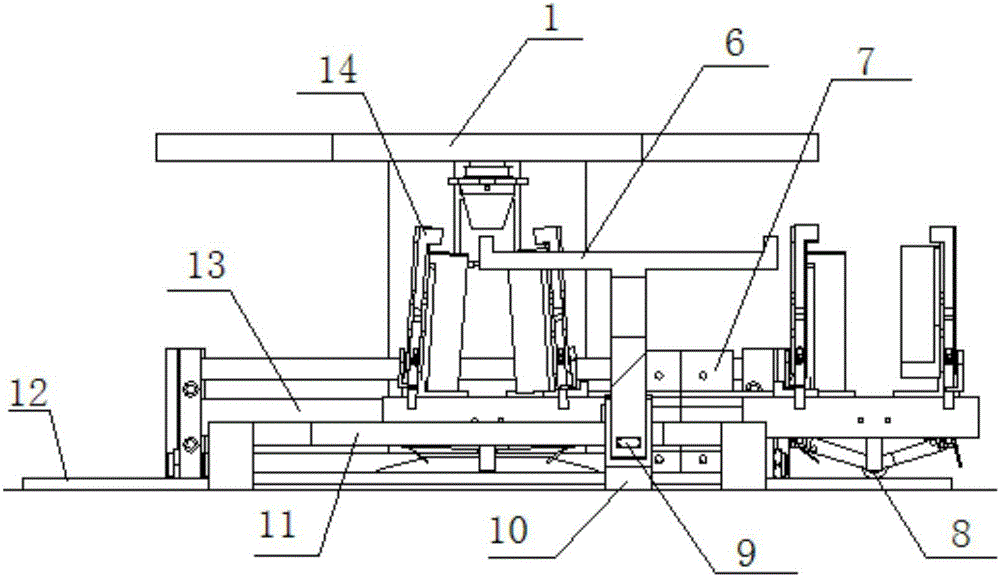

[0031] An automatic packaging equipment, including a filling machine, a packaging bag opening and conveying mechanism, a direct feeding mechanism, a vacuuming and sealing mechanism, and a conveyor belt. A packaging bag opening and conveying mechanism is provided below the filling machine. The outside of the packaging bag opening and conveying mechanism is provided with a direct feeding upper loading mechanism, the packaging bag opening and conveying mechanism is provided with a vacuum and sealing mechanism, and the vacuum and sealing mechanism is provided with a conveyor belt;

[0032] The packaging bag opening and conveying mechanism is a reciprocating motion filling and conveying mechanism, including a slide table, guide wheels, bag opening arms, carriages, carriage guide wheels, cylinders, claws, vertical cams and horizontal cams. The lower end of the table is provided with slide guide rails, the cylinder, slide table and carriage are connected in parallel in turn, the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com