Automatic labeler

A labeling machine and automatic technology, which is applied in the field of packaging production line technology and equipment, can solve the problems of limited application range, inability to apply at the same time, large winding radius, etc., and achieve the effects of high degree of automation, easy operation, and reduced replacement frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in combination with real-time examples and accompanying drawings, but the protection scope of the present invention is not limited to the embodiments.

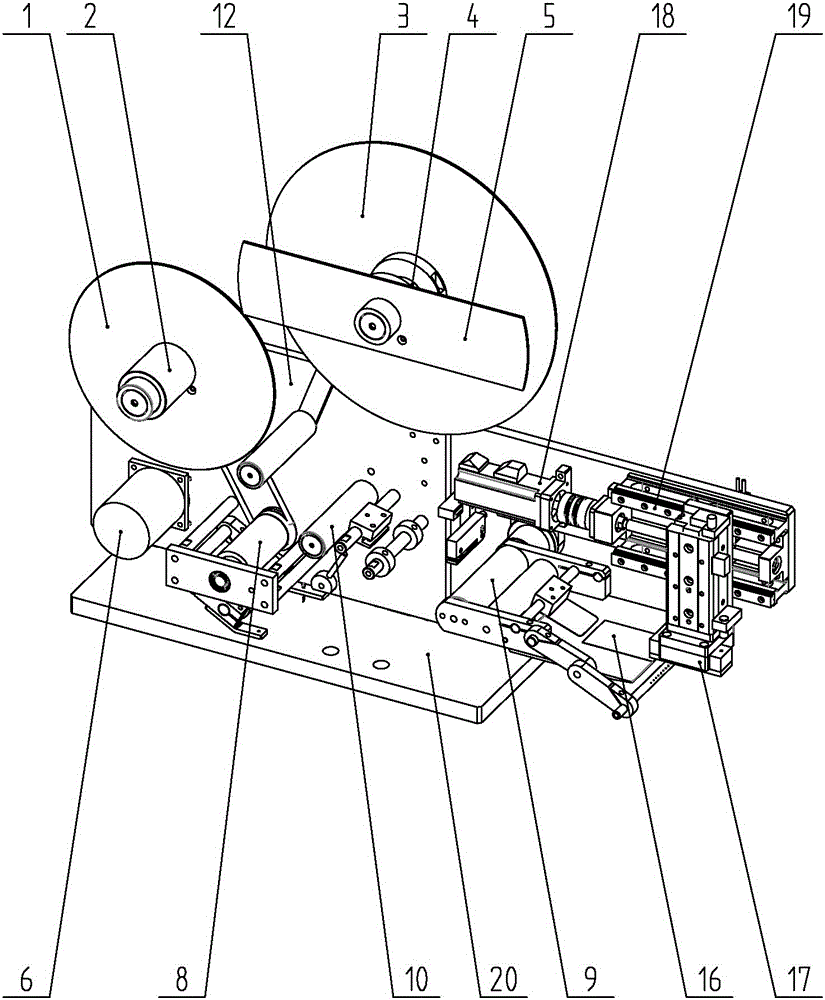

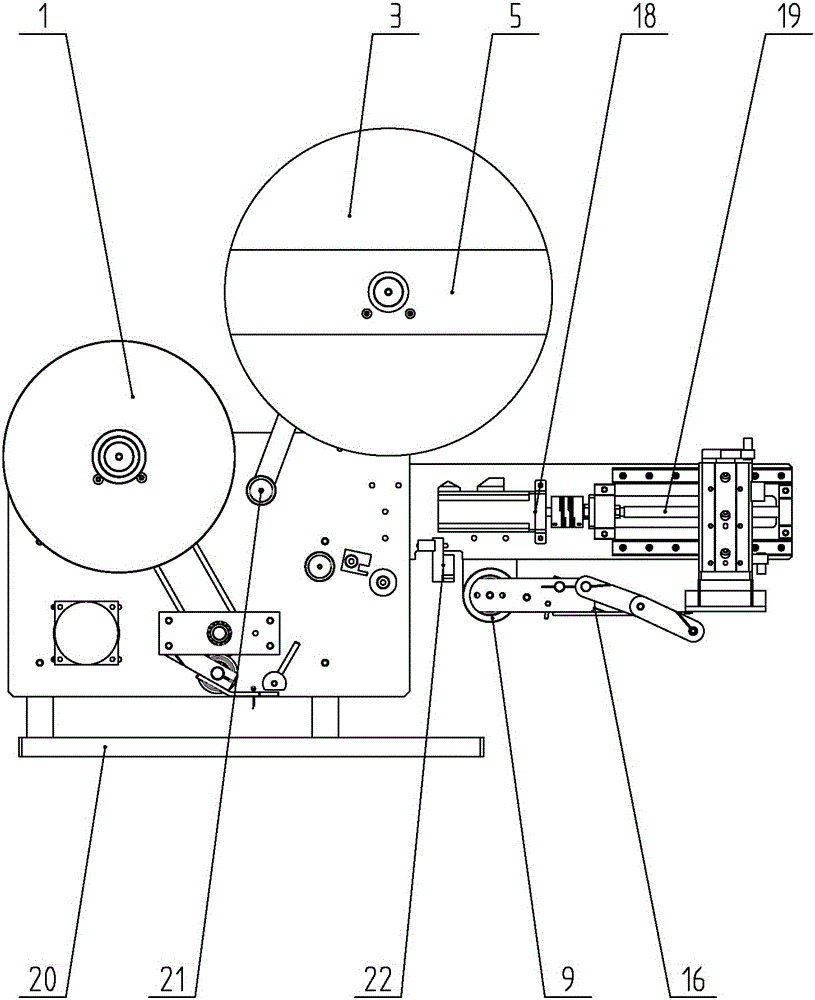

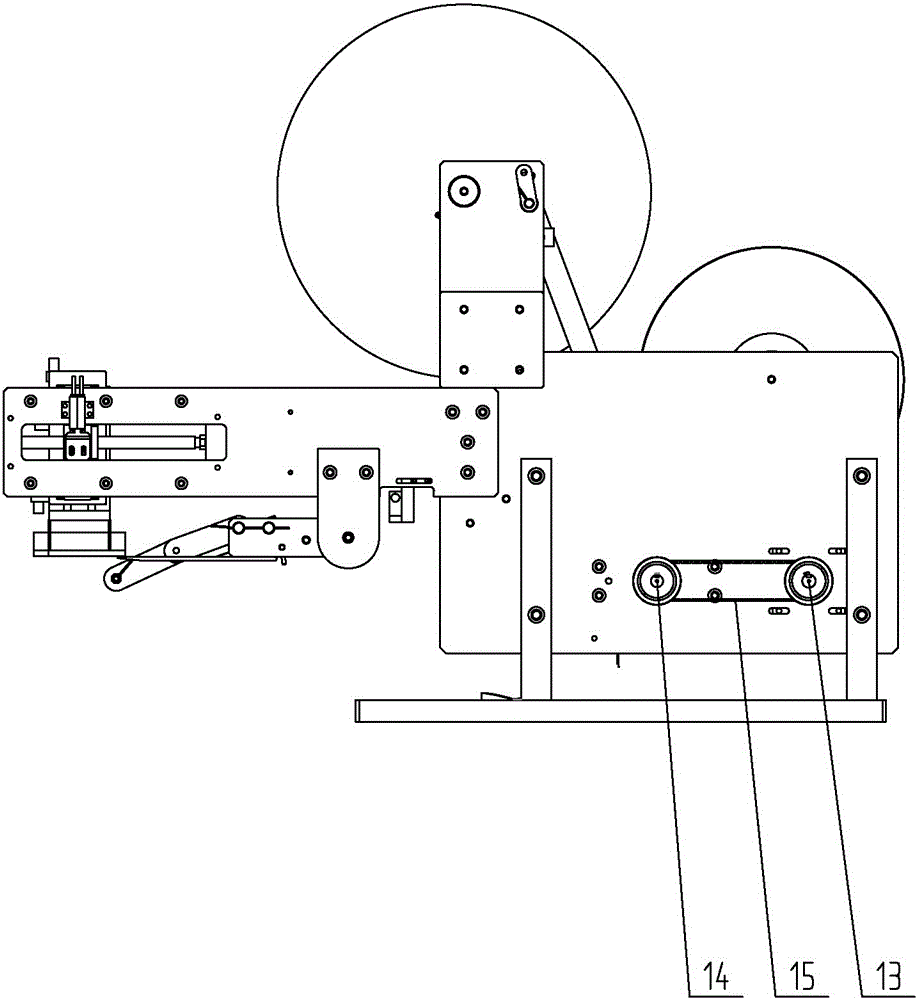

[0030] Such as Figures 1 to 6 As shown, an automatic labeling machine includes a machine table 20, a label moving mechanism, a labeling mechanism and a driving mechanism.

[0031] The machine platform 20 is provided with a vertical fixing plate 12 for fixing other components.

[0032] The labeling mechanism includes a support, a screw drive mechanism 19, a labeling platform 16, an inductor 22 and a cylinder 17. The support is installed on the fixed plate 12, and the lead screw transmission mechanism 19 is horizontally installed on the support, and the lead screw transmission mechanism 19 is driven by the lead screw motor 18 so that the slider therein can move horizontally. Cylinder 17 is installed vertically downwards on the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com