Drive drawing mechanism of enameling machine wire storage device

The technology of a traction mechanism and a wire storage device is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

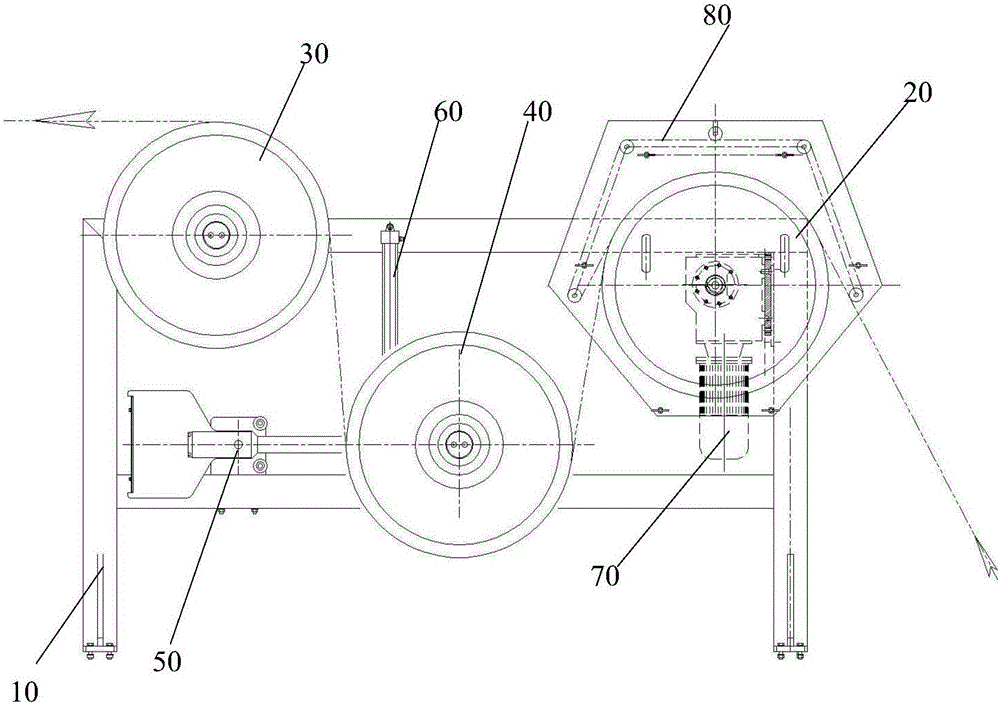

[0015] Next, an active pulling mechanism of an enamelling machine wire accumulator as an example of the present invention will be described based on the drawings.

[0016] figure 1 It is an enlarged schematic diagram showing the active traction mechanism of the enamelling machine wire storage device of the present invention.

[0017] Such as figure 1 As shown, the active traction mechanism of the wire storage device of the enamelling machine of the present invention has a frame body 10 , a traction wheel 20 , an output wheel 30 , a traction control wheel 40 , a rotary encoder 50 and a damping cylinder 60 .

[0018] The traction wheel 20 and the output wheel 30 are installed at both ends of the frame body 10 , and the traction control wheel 40 is installed on the frame body 10 between the traction wheel 20 and the output wheel 30 .

[0019] The traction wheel 20 is connected to the drive motor 70 via a reduction mechanism (not shown), the traction control wheel 40 abuts again...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com