A kind of aniline sewage decolorization treatment agent and its preparation method and use method

A treatment agent and decolorizing agent technology, applied in water/sewage treatment, adsorption water/sewage treatment, reduced water/sewage treatment, etc., can solve the problems of severe corrosion of high-pressure reactors, poor water solubility and toxicity of ozone, and limited industrial applications. Achieve the effects of reducing aniline content, facilitating management, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

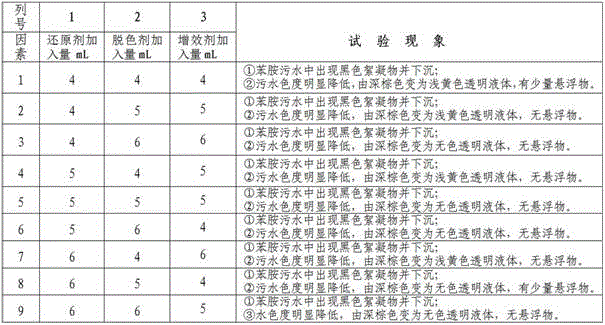

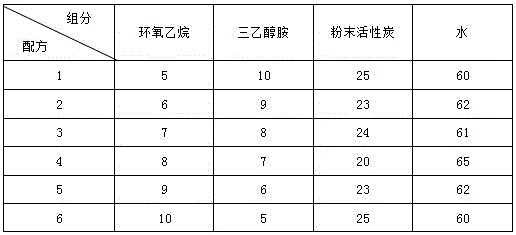

Examples

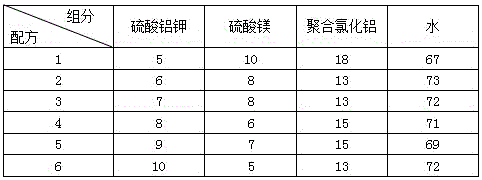

preparation Embodiment 1

[0023] Reductant preparation example 1: According to the data in formula 1 in Table 1, add 67 grams of water to the reaction kettle, add 5 grams of aluminum potassium sulfate while stirring, slowly heat up to 45 ° C and stir for at least 30 minutes; Slowly add 10 grams of magnesium sulfate and 18 grams of polyaluminum chloride while stirring; heat the above solution to 45°C, stir for at least 1.5 hours and then cool to room temperature. The finished product is a pale yellow liquid with a pH value of 4.7.

preparation Embodiment 2

[0024] Reductant preparation example 2: According to the data in formula 2 in Table 1, add 73 grams of water to the reaction kettle, add 6 grams of aluminum potassium sulfate while stirring, slowly heat up to 45 ° C and stir for at least 30 minutes; Slowly add 8 grams of magnesium sulfate and 13 grams of polyaluminum chloride while stirring; heat the above solution to 60°C, stir for at least 1.5 hours and then cool to room temperature. The finished product is a light yellow liquid with a pH value of 4.6.

preparation Embodiment 3

[0025] Reductant preparation example 3: According to the data in formula 3 in Table 1, add 72 grams of water to the reaction kettle, add 7 grams of aluminum potassium sulfate while stirring, slowly heat up to 45 ° C and stir for at least 30 minutes; Slowly add 8 grams of magnesium sulfate and 13 grams of polyaluminum chloride while stirring; heat the above solution to 50°C, stir for at least 1.5 hours and then cool to room temperature. The finished product is a light yellow liquid with a pH value of 4.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com