Third-section acid pickling integrated well completion pipe string and method

A completion pipe string and pickling technology, which is applied in the direction of earthwork drilling, wellbore/well components, cleaning equipment, etc., can solve the problems of poor pickling effect, high operating cost, and long well-occupancy period, so as to improve efficiency , The effect of simplifying the acid washing completion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with specific examples, but not as a limitation of the present invention. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

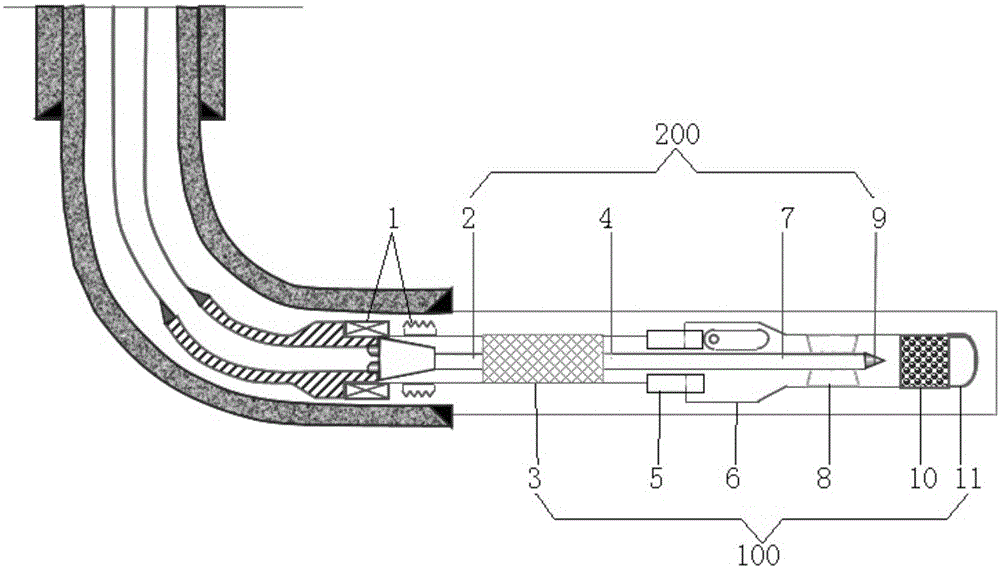

[0022] figure 1 It is a structural schematic diagram of the three-opening acid-washing integrated completion string in the embodiment of the present invention. like figure 1 As shown, the three-opening acid-washing integrated completion string includes the hanging packer 1, the three-opening acid-washing integrated well-staying string 100 and the three-opening acid-washing integrated service string 200, and the hanging packer 1 is For the double-suspension packer, the three-opening acid-washing integrated well-staying string is connected to the outer suspension ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap