Rock-drilling carriage assembly device of extreme-thin ore layer electric coal drill

A combined device and ultra-thin mine technology, which is applied in ground mining, earth drilling, underground mining, etc., can solve the problems of increased production costs and increased wall-cutting engineering volume, and achieve the reduction of mining power consumption, high labor intensity, and The effect of high mining labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below:

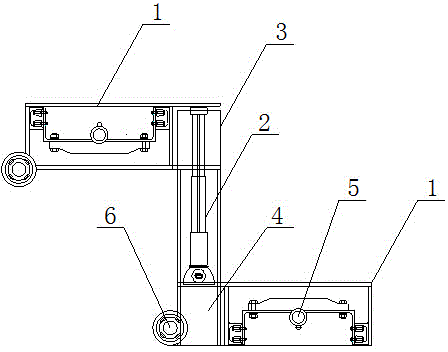

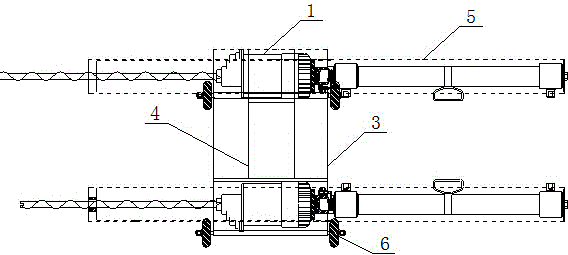

[0014] Such as figure 1 , figure 2 As shown, a combination device for electric drilling and rock drilling for extremely thin seam coal is characterized in that the combination device includes a set of electric drill frames 1, and the electric drill frames 1 are fixedly connected by lifting brackets 3, and inside the lifting brackets 3 A jack 2 is provided, and the lower end of the lifting bracket 3 is connected to the sliding guide rail 4, and the lifting bracket 3 can move back and forth on the sliding guide rail 4; the electric drill frame 1 is provided with a coal electric drill 5 in the same direction. 1 lower end is equipped with one group of walking wheels 6.

[0015] When the present invention is used in practice, the combined device is also externally connected with an air compressor with a rated air pressure of 0.8MPA, an external size of 54*27*66cm, a power of 1.5KW, an air supply volume of 0.206m3 / min, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap