Exhaust gas turbocharger with a rotor

An exhaust gas turbine and exhaust gas booster technology, which is applied in the direction of rotating bearings, turbine/propulsion device lubrication, engine lubrication, etc., can solve limited problems and achieve the effect of improved installation and quiet operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

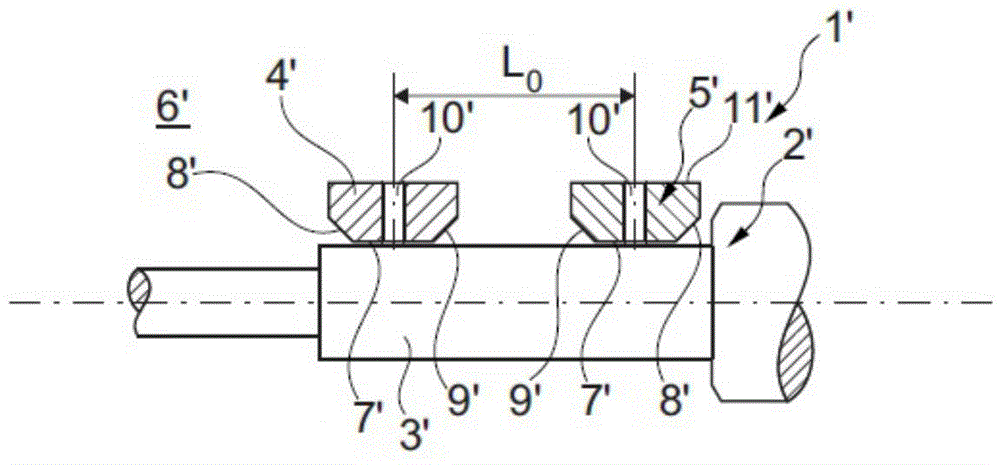

[0018] according to figure 1 , an exhaust gas turbocharger 1' according to the prior art comprises a rotor 2' whose shaft 3' is mounted in a bearing housing 6' via two radial bearing bushes 4' and 5'. The two radial bearing bushes 4' and 5' respectively have two bevels 8' and 9' on their inner surface 7' facing the shaft 3', wherein the bevels 8' and 9' are formed to have the same dimensions. This produces a center-to-center axial spacing L of the two inner surfaces 7' 0 .

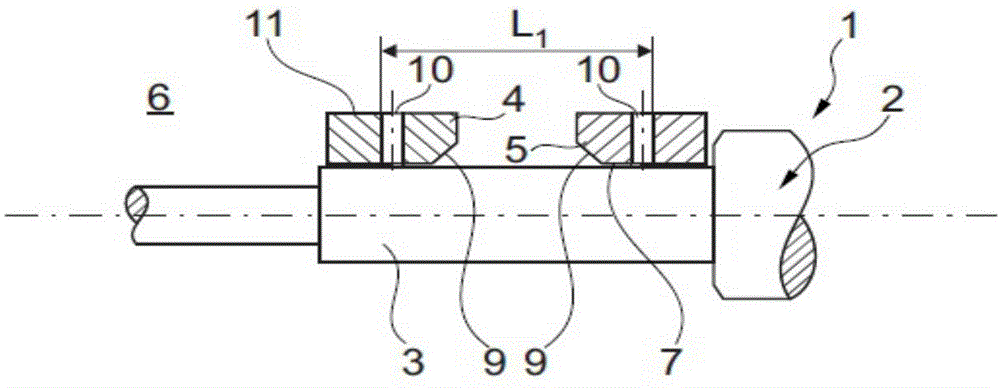

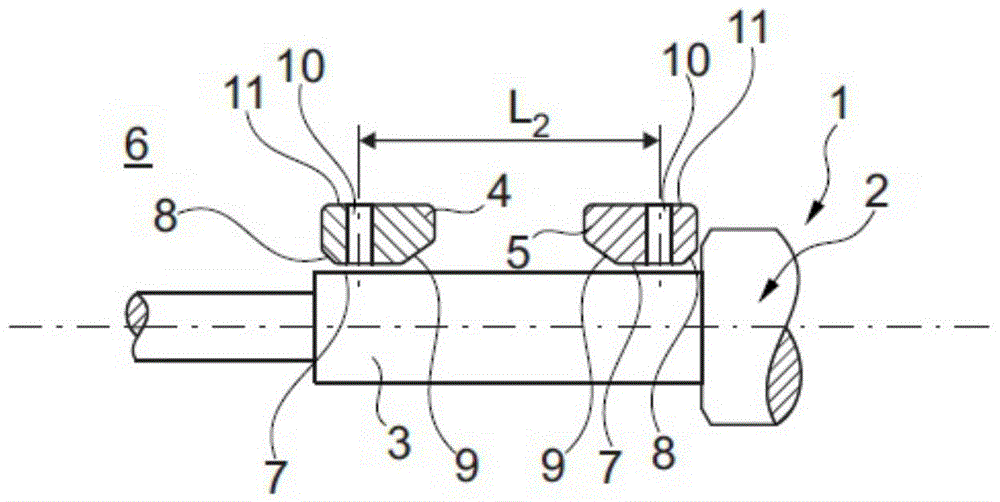

[0019] according to Figure 2 to Figure 4 , the exhaust gas turbocharger 1 according to the invention similarly comprises a rotor 2 whose shaft 3 is mounted in a bearing housing 6 via two radial bearing bushes 4 , 5 . and figure 1 In this case, by contrast, the reference numerals are written without an apostrophe. see figure 2 It is presently evident that each of the two radial bearing bushes 4 , 5 according to the invention has only a single bevel 9 on its inner surface 7 facing the shaft 3 , which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com