Pipeline maintenance and first-aid repair pipe clamp

A pipeline and arc-shaped technology, which is applied in the field of pipeline maintenance and repair, can solve the problems of small pipeline deformation and low plugging success rate, and achieve the effects of reduced jacking force, good adaptability, and simple and flexible structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

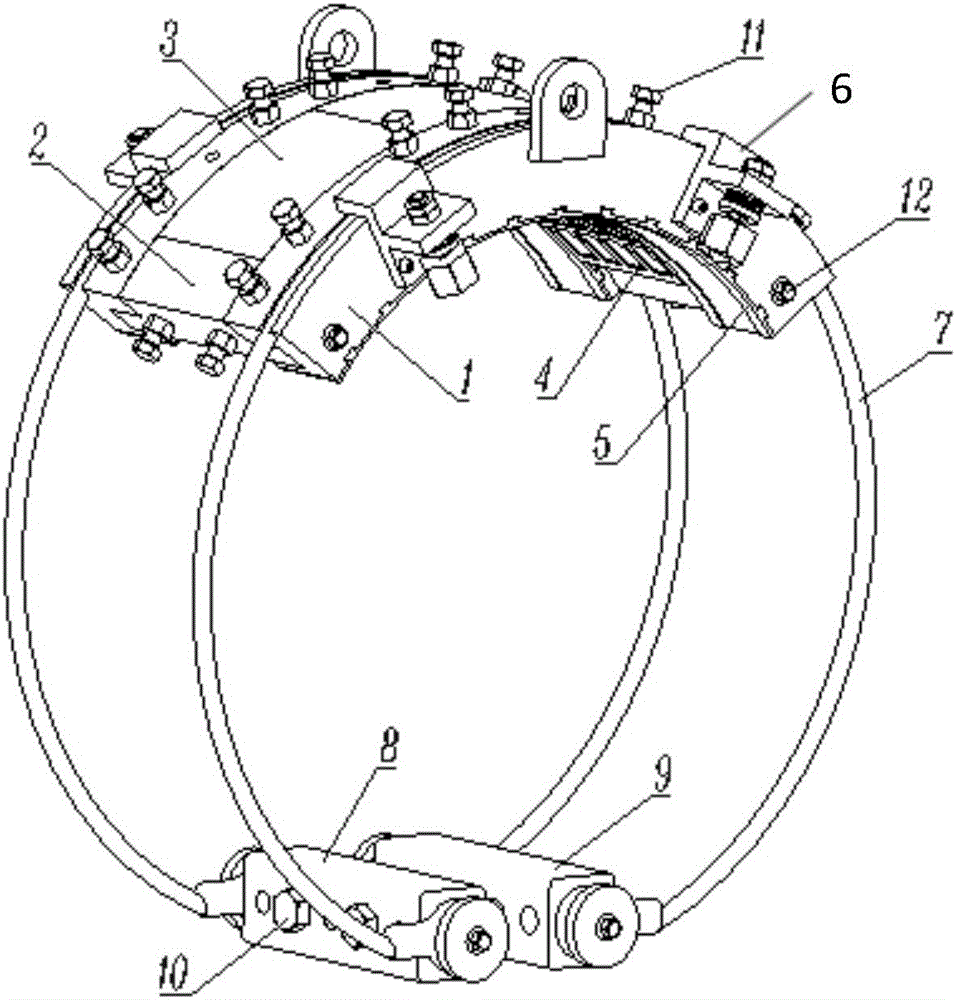

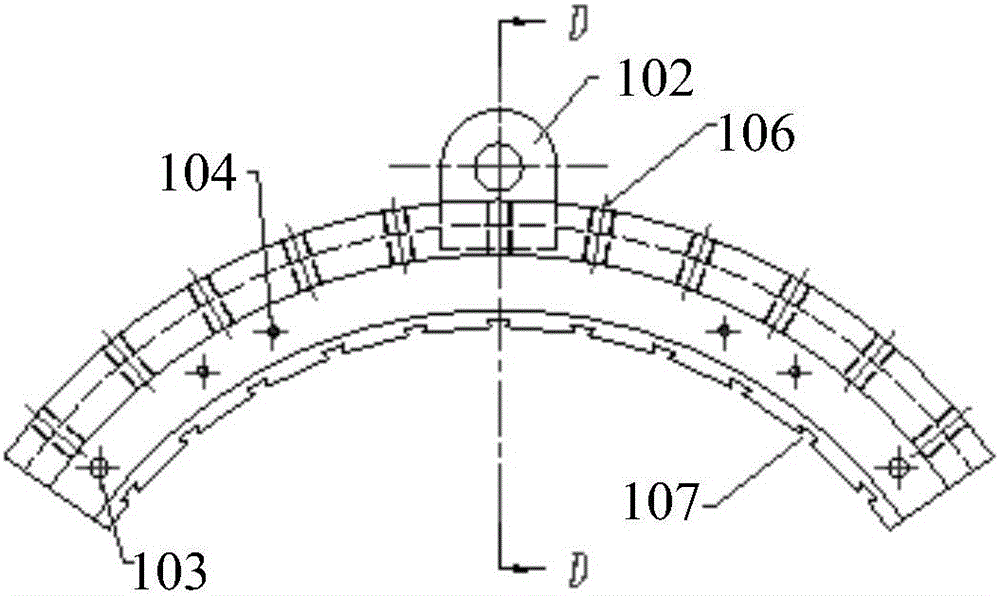

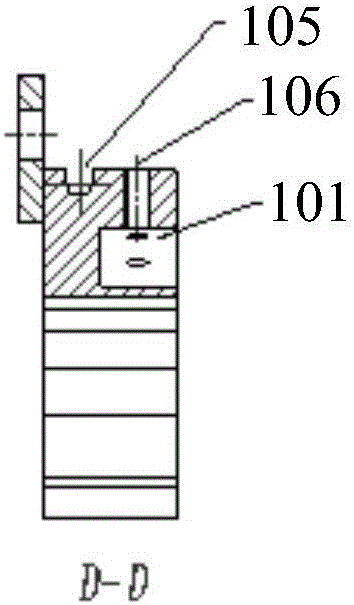

[0045]The present invention differs from the prior art in the following key points: 1: Utilize the arc-shaped compression block to press the sealing rubber pad with grid-like sealing strips to block the leaking part of the pipeline, and seal the surface of the pipeline around the leaking part to form a multi-layer multi-layer The sealing method of the pipeline makes the present invention suitable for sealing large-area leakage, cracks or perforations of medium and high pressure pipelines, and has good adaptability to pipeline deformation deviation and good sealing reliability. 2: The unique design of the assembled rigid arc-shaped frame, the adjustable combined arc-shaped pressing block, the grid-shaped sealing strip sealing rubber pad, and the flexible sling binding and fixing makes the present invention light in weight and compact in structure. Simple and flexible, easy and labor-saving installation and adjustment, convenient for land and underwater sealing construction.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com