Method and device for applying exciting force in spatial direction

A technology of spatial direction and application device, applied in the field of excitation force application, measurement error calibration of test instruments, and vibration testing, which can solve the problem that the excitation force direction cannot be changed in space, the output displacement cannot be freely adjusted, and the structure of the exciter Stability and other issues, to achieve the effect of novel structure, high positioning accuracy and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

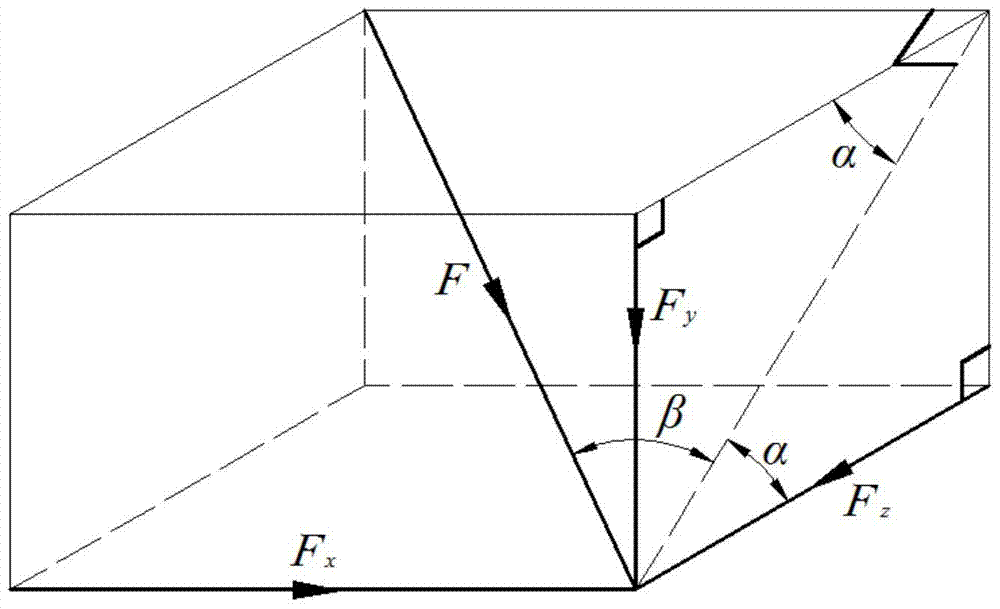

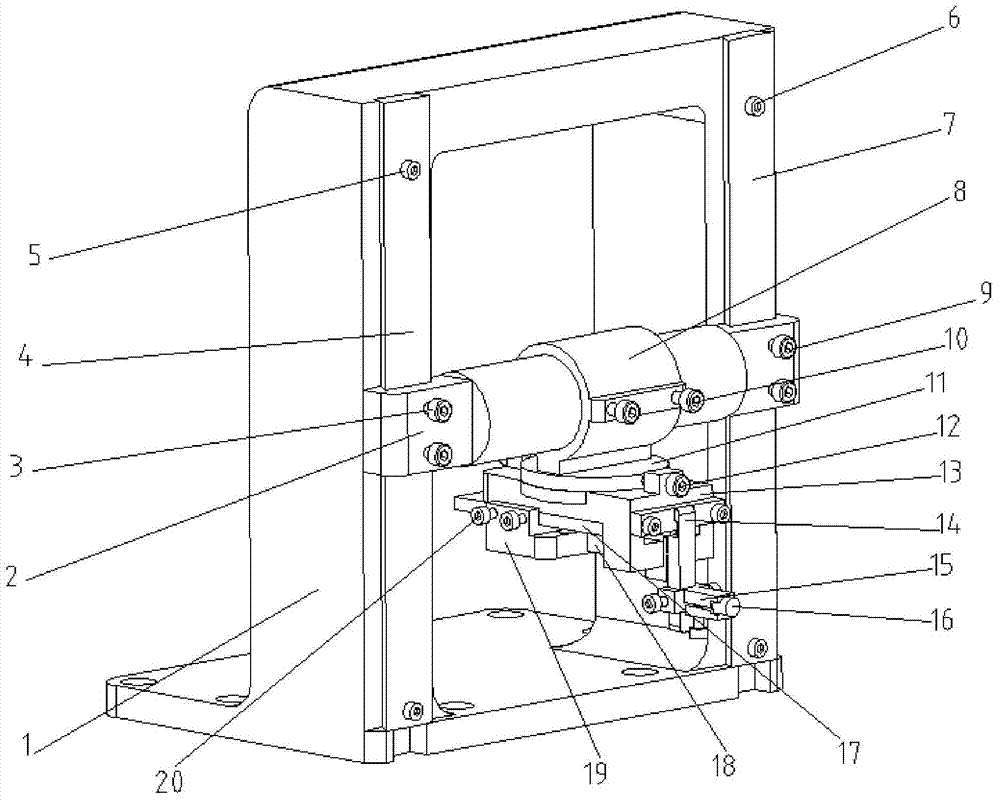

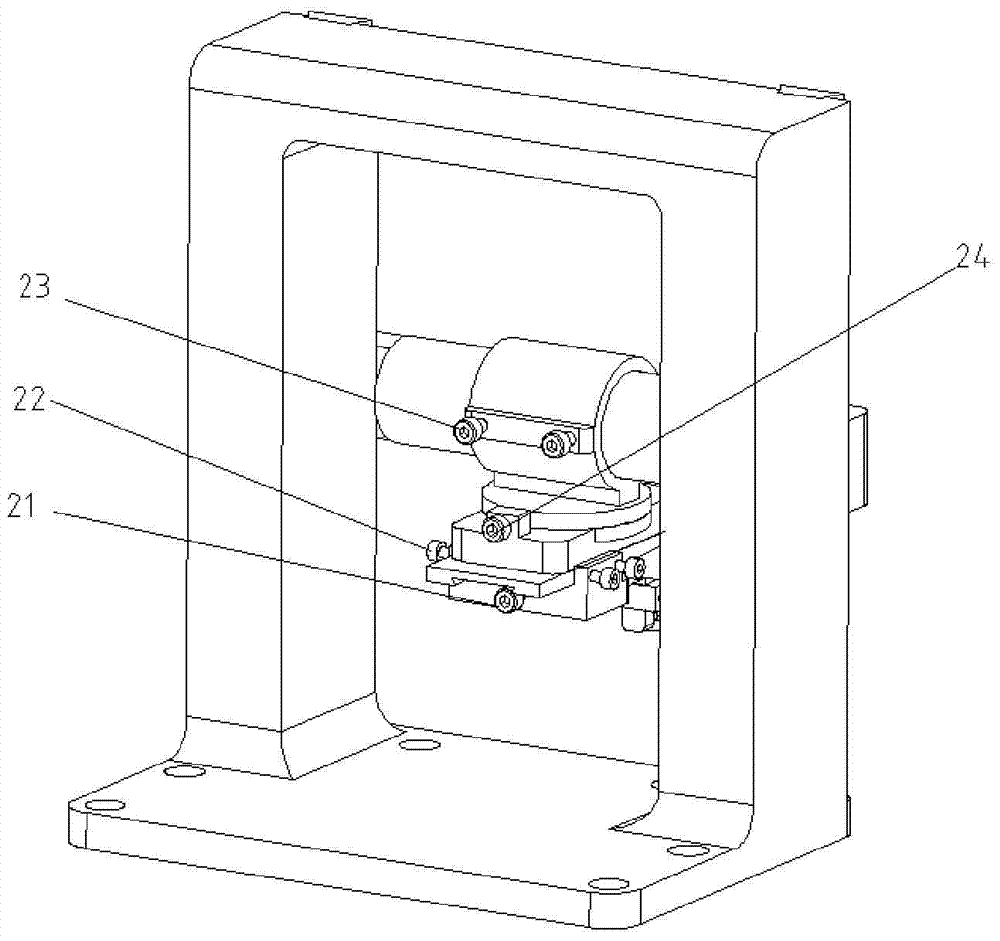

[0042] A method for applying an exciting force in a spatial direction, comprising the following steps:

[0043] (1) Move the vertical (Y direction) moving body to an appropriate height along the two vertical guide rails, and fix the position with set screws;

[0044] (2) Move the horizontal (X direction) moving and rotating block to an appropriate position along the cylindrical part of the vertical moving body;

[0045] (3) Rotate the horizontally moving and rotating block around the cylindrical part of the vertical moving body at a certain angle, and fix the position with a set screw, so that the angle between the axis of the pressure sensor and the horizontal direction is α;

[0046] (4) Rotate the piezoelectric stack bracket around the fixed disc by a certain angle β, and fix the position with a set screw;

[0047] (5) Move the clamping mechanism of the pressure sensor to an appropriate position along the long arm of the lever amplification mechanism, and fix the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com