Device and method for measuring column capacity of chromatographic column

A column capacity, ion chromatography column technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of high pressurization of stationary phase, complex operation process, pressure fluctuation, etc., achieve pulse supply pressure relief, overcome technical defects, The effect of reducing volatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

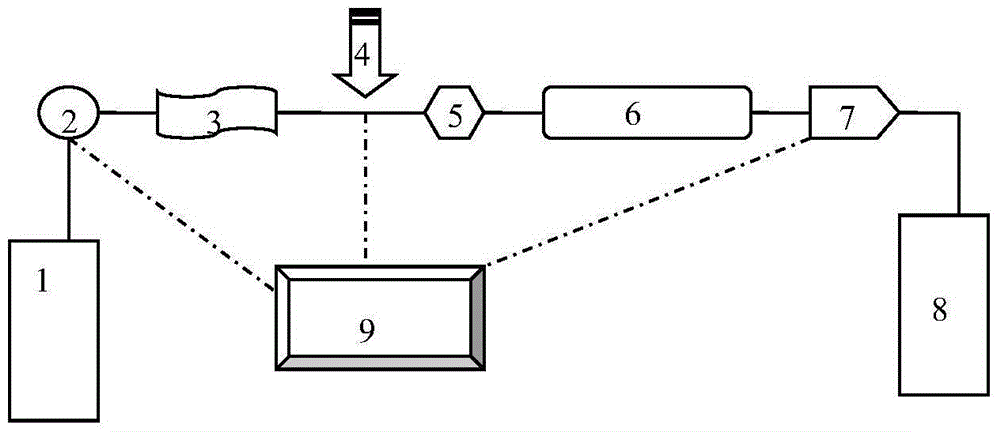

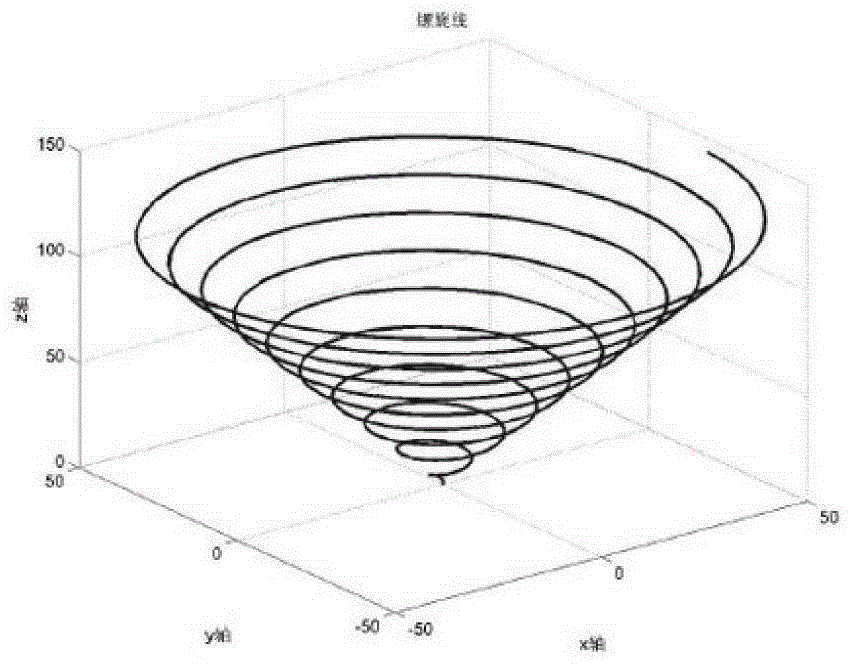

[0013] The present invention will be further described below in conjunction with specific embodiments, as appended figure 1 , as shown in 2.

[0014] A device for measuring the capacity of a chromatographic column, comprising the following components: a buffer solution storage tank 1, a pump 2, a slow flow device 3, a sample injection syringe 4, a guard column 5, a chromatographic column to be tested 6, a detector 7, and waste liquid collection Tank 8, liquid circulation pipeline, data line, computer terminal 9 with data processing and control and display functions; the liquid circulation pipeline is connected to the following components in sequence: buffer solution storage tank 1, pump 2, slow flow device 3, sample injection syringe 4 , a guard column 5, a chromatographic column to be tested 7, a detector 7, and a waste liquid collection tank 8; and, the pump 2, the injection syringe 6, and the detector 7 are connected to the terminal 9 through data lines.

[0015] The flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com