High temperature and high pressure heat tracking compensation adiabatic static oxidation and dynamic oxidation displacement device

A high temperature and high pressure, heat tracking technology, applied in the direction of material inspection products, etc., can solve the problems of the reactor cannot be insulated, the heat loss of the reactor, the difficulty of heat accumulation, etc., to improve the oil recovery rate, reduce the viscosity of the crude oil, and increase the mixing intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

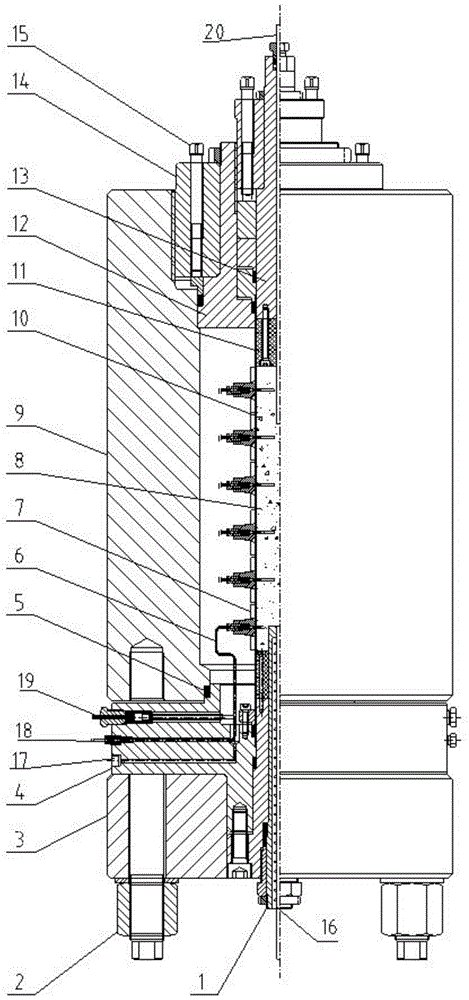

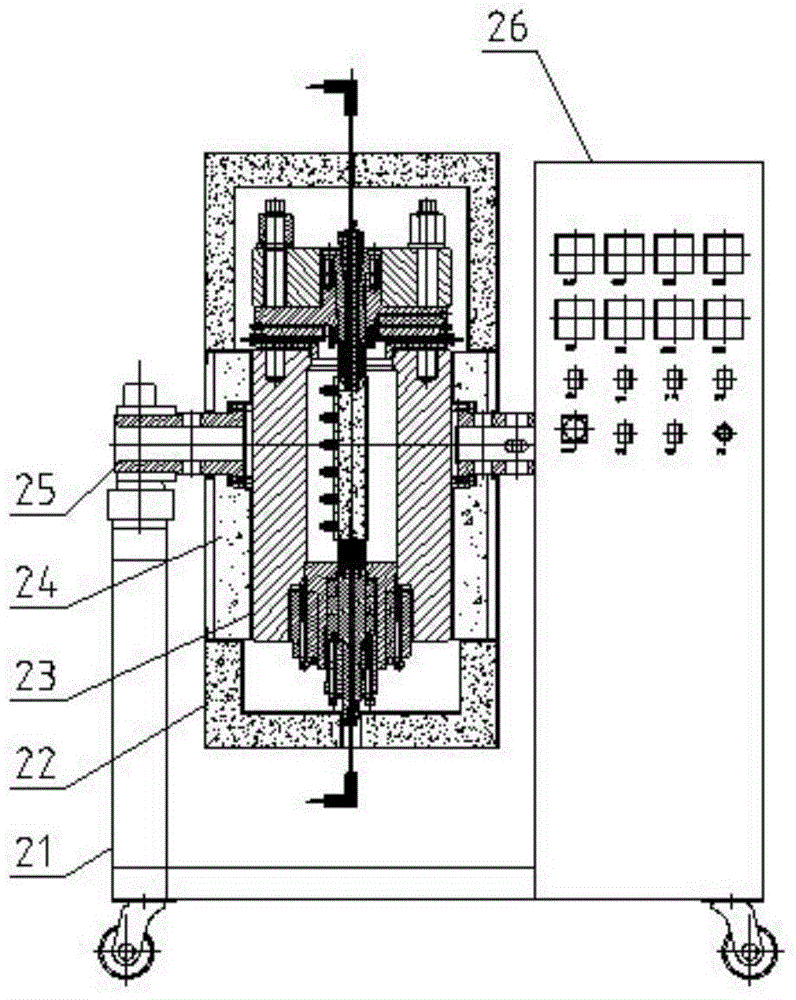

[0029] During the static oxidation experiment, inert gas is injected from the annular pressure port 17 to keep the internal pressure of the metal sleeve 8 consistent with the external annular pressure, and air or oxygen is injected from the air injection port 16. Generally, only low-temperature oxidation experiments are performed in static experiments. In the process, the gas and the sample 10 carry out an oxidation reaction; the temperature data of the temperature field are derived through the thermocouple interface 18, and if the temperature inside the metal sleeve 8 and the temperature at the center of the metal sleeve 8 exceed the set threshold value, the temperature field is controlled by a program. The temperature can be quickly compensated without exceeding the temperature of the reaction center, so that the internal temperature of the whole experiment can be balanced, and the heat loss of the center part can be reduced to the outside, so as to understand the effect of st...

Embodiment 2

[0031]In the dynamic oxidation displacement experiment, inert gas is injected from the annular pressure port 17 to keep the internal pressure of the metal sleeve 8 consistent with the external annular pressure, and air or oxygen is injected from the air injection port 16. In the high temperature oxidation experiment, the gas and the sample 10 Oxidation reaction is carried out, and in the combustion displacement experiment, when the temperature cannot reach spontaneous combustion, the sample 10 is combusted with oxygen to generate heat to form a displacement heat front through the action of the igniter 1. Both the high temperature oxidation experiment and the combustion displacement experiment The temperature data of the temperature field is derived through the thermocouple interface 18. If the temperature inside the metal sheath 8 and the temperature of the center of the metal sheath 8 exceed the set threshold, the temperature of the temperature field can be compensated quickly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com