Propane-injecting shallow heavy oil reservoir exploitation method

A production method and technology for heavy oil reservoirs, which can be applied in the fields of production fluids, earthwork drilling, wellbore/well components, etc., and can solve the problems of unpublished polymer gel formulation system viscosity, limited recovery rate, environmental pollution, etc. , to achieve the effect of reducing propane loss and production cost, reducing crude oil viscosity, and avoiding large flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment provides a method for producing shallow heavy oil reservoirs by injecting propane. The main oil layer of the shallow heavy oil reservoirs is buried shallow, with an average buried depth of 300m, an original reservoir pressure of 2.8 MPa, and an original reservoir temperature of 19 °C; the viscosity of crude oil is high, the viscosity of degassed crude oil at the reservoir temperature is 1.05 million centipoise, and the average effective thickness of the reservoir is 15m.

[0058] The method for producing propane injection in shallow heavy oil reservoirs provided in this embodiment includes the following specific steps:

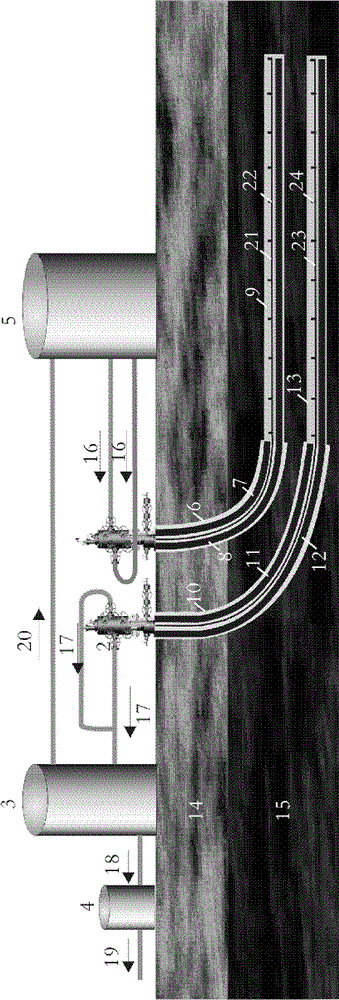

[0059] A. Deploy horizontal injection-production well pattern

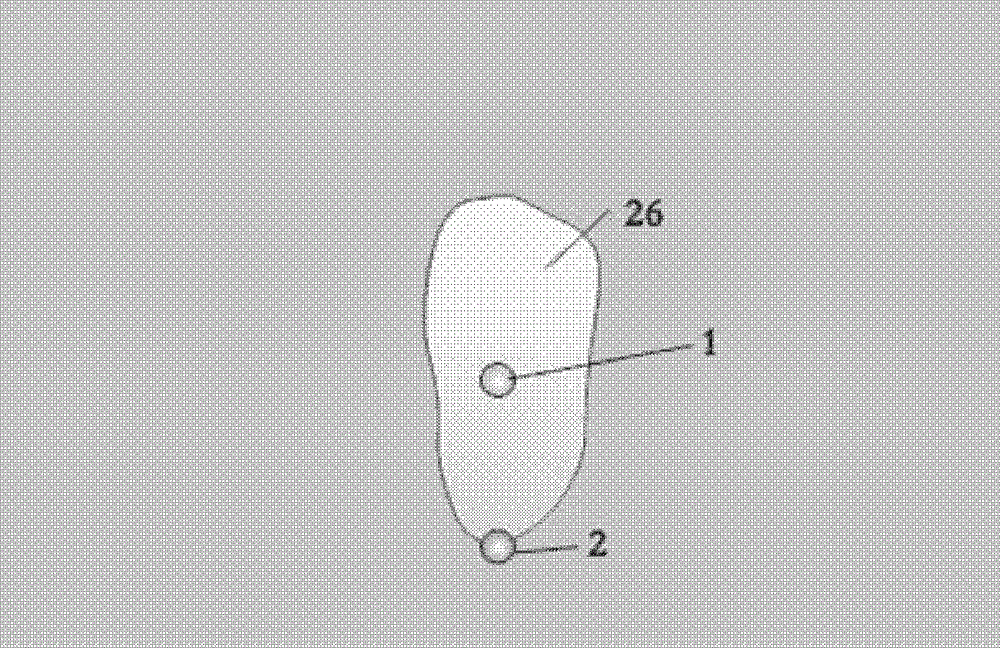

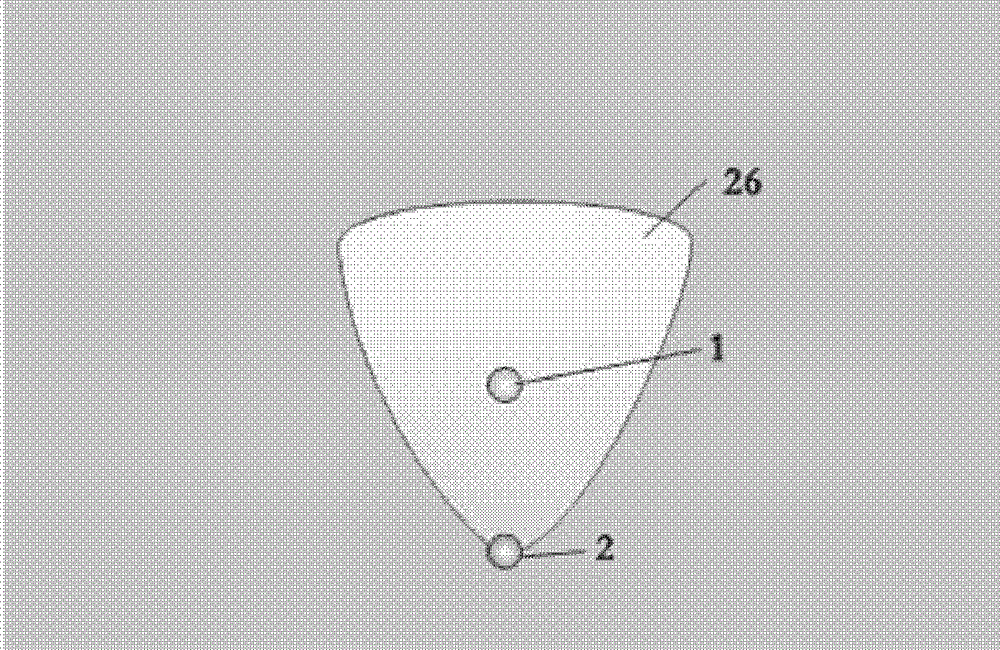

[0060] First, deploy injection wells (horizontal injection wells) 1 and production wells (horizontal injection wells) 2 in the main heavy oil layer 15 of the shallow heavy oil reservoir. The injection wells 1 and production wells 2 are located on the same plane. The distanc...

Embodiment 2

[0083] This embodiment provides a propane injection production method for a shallow heavy oil reservoir, the shallow heavy oil reservoir is the oil layer of the Badaowan Formation in the shallow heavy oil area of Fengcheng, Xinjiang Oilfield, and the main oil layer of the heavy oil area The average buried depth is 220m, the average effective thickness of the reservoir is 17m, the original reservoir pressure is 2.0MPa, the original reservoir temperature is 17°C, and the viscosity of degassed crude oil at the reservoir temperature is 870,000 centipoise.

[0084] The method for producing propane injection in shallow heavy oil reservoirs provided in this embodiment includes the following specific steps:

[0085] A. Deploy horizontal wells

[0086] First, deploy injection wells (horizontal injection wells) 1 and production wells (horizontal injection wells) 2 in the main heavy oil layer 15 of the shallow heavy oil reservoir. The injection wells 1 and production wells 2 are locate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com