Micro-motion induction switch

A touch switch and switch technology, applied in the field of sensors, can solve problems such as poor contact, lack of overheating protection, and short service life, and achieve the effects of reducing the possibility of false triggering, novel and reasonable structure, and clear on and off states

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

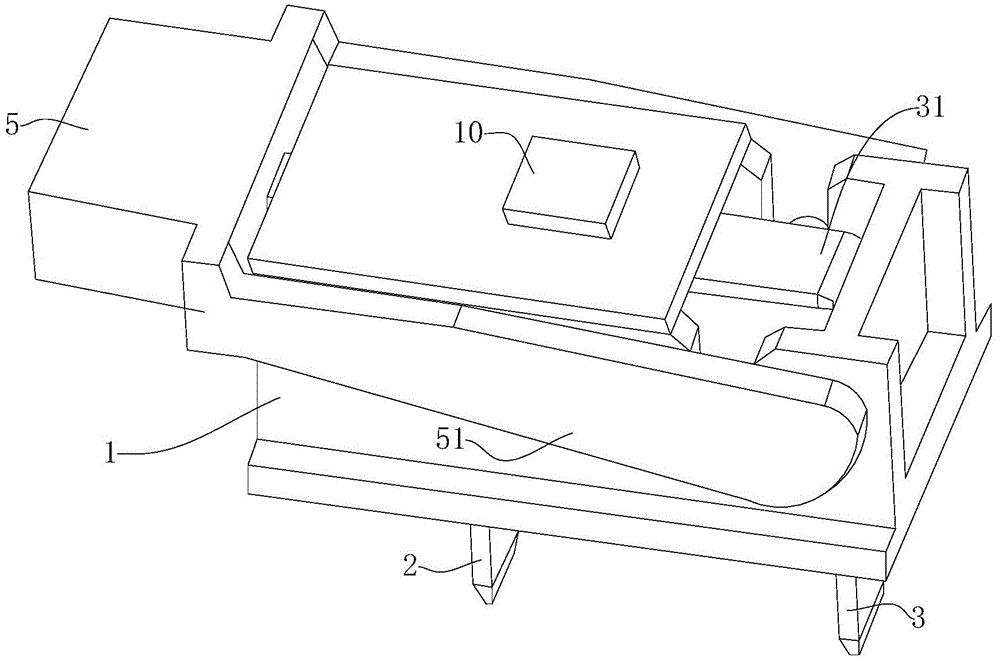

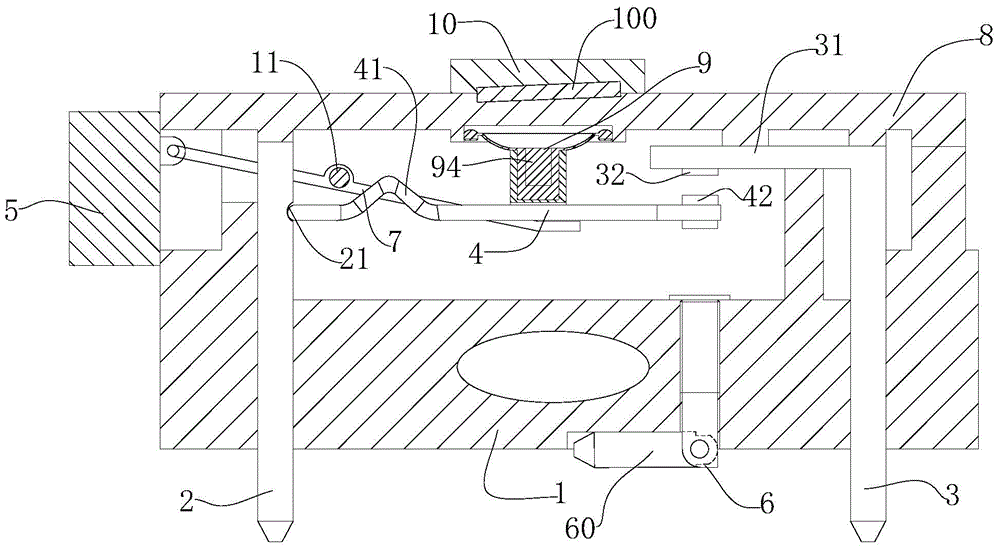

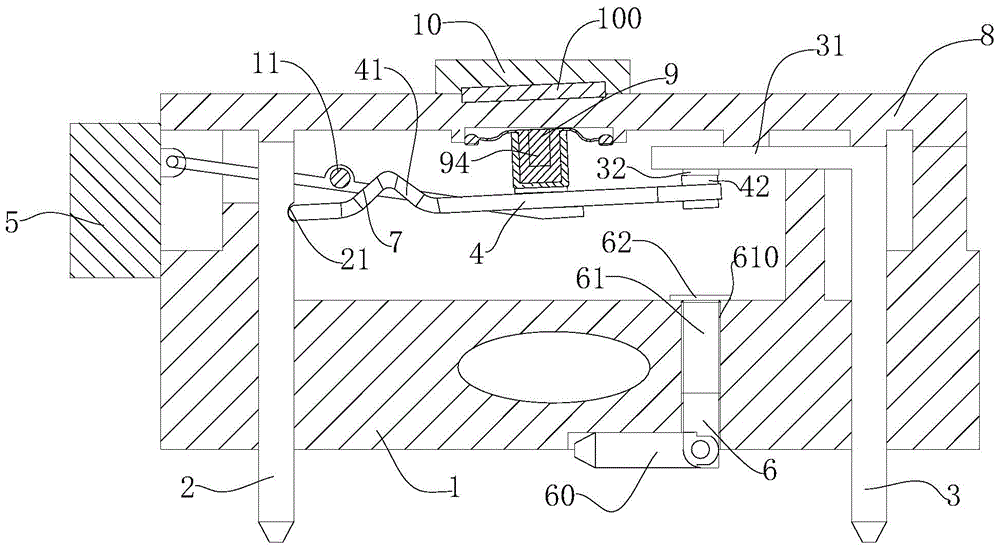

[0040] Such as Figure 1-9 The micro-motion sensor switch shown is composed of a housing 1, a touch switch and a touch pressure block 5. The top of the housing 1 is an upper cover 8, and two wing plates 51 are provided on one side of the touch block 5, and the two wing plates 51 are symmetrically spaced apart.

[0041] The inner side of the distal end of the wing plate 51 is provided with a T-shaped clip connection end 52, and the two sides of the housing 1 corresponding to the clip connection end 52 are respectively provided with a notch 13 hinged to the clip connection end. The touch pressure block 5 is movably hinged on the outside of the housing 1 through a snap connection end 52 at its distal end, and is connected to a touch switch. The touch pressure block 5 can move up and down with the pressure, thereby driving the touch switch to complete the on and off action. The above-mentioned tact switch main body is installed in the housing 1, and the upper cover 8 covers the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com