Board feeding machine of flexible circuit board pretreatment line

A flexible circuit board and board machine technology, which is applied to the assembly of printed circuits with electrical components and PCB positioning during processing, can solve the problems of low manual counting efficiency, high labor intensity of workers, and pre-processing line jams, etc., to achieve The structure is simple and reasonable, the degree of automation is high, and the effect of single-machine efficiency and speed improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

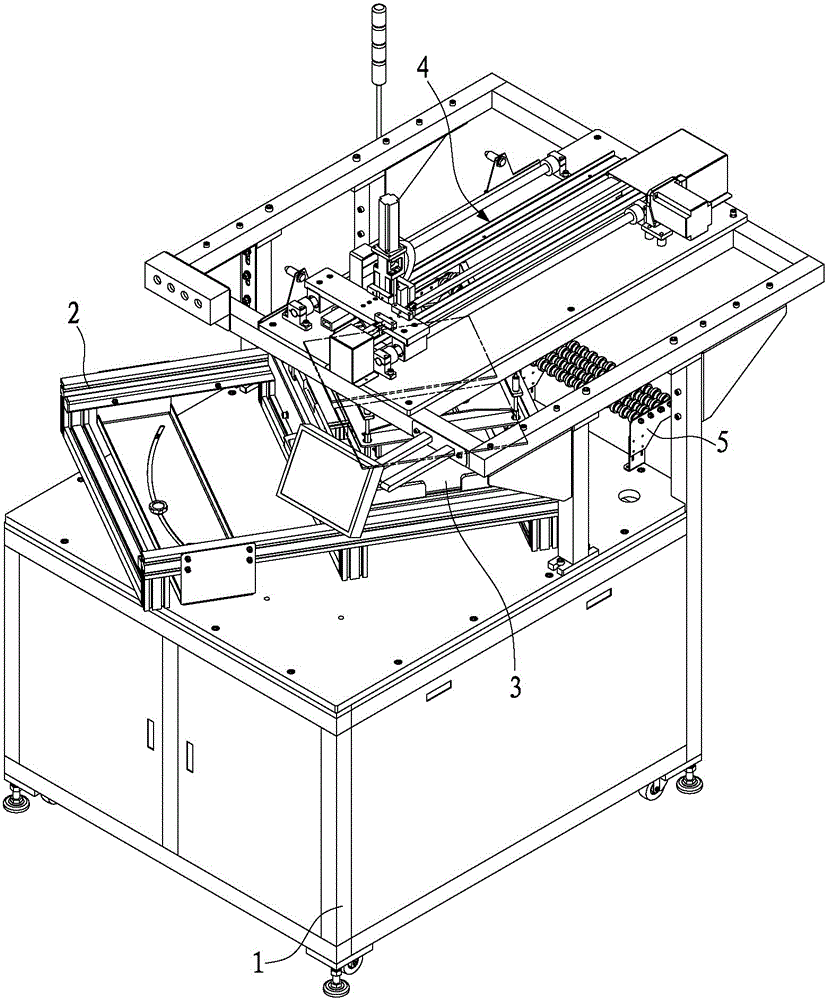

[0028] Such as figure 1 As shown, the present invention is a loading machine for a pre-processing line of flexible circuit boards, including a frame assembly 1 , a magazine bracket 2 , an adjustable magazine assembly 3 , a feeding assembly 4 and a transition bracket assembly 5 .

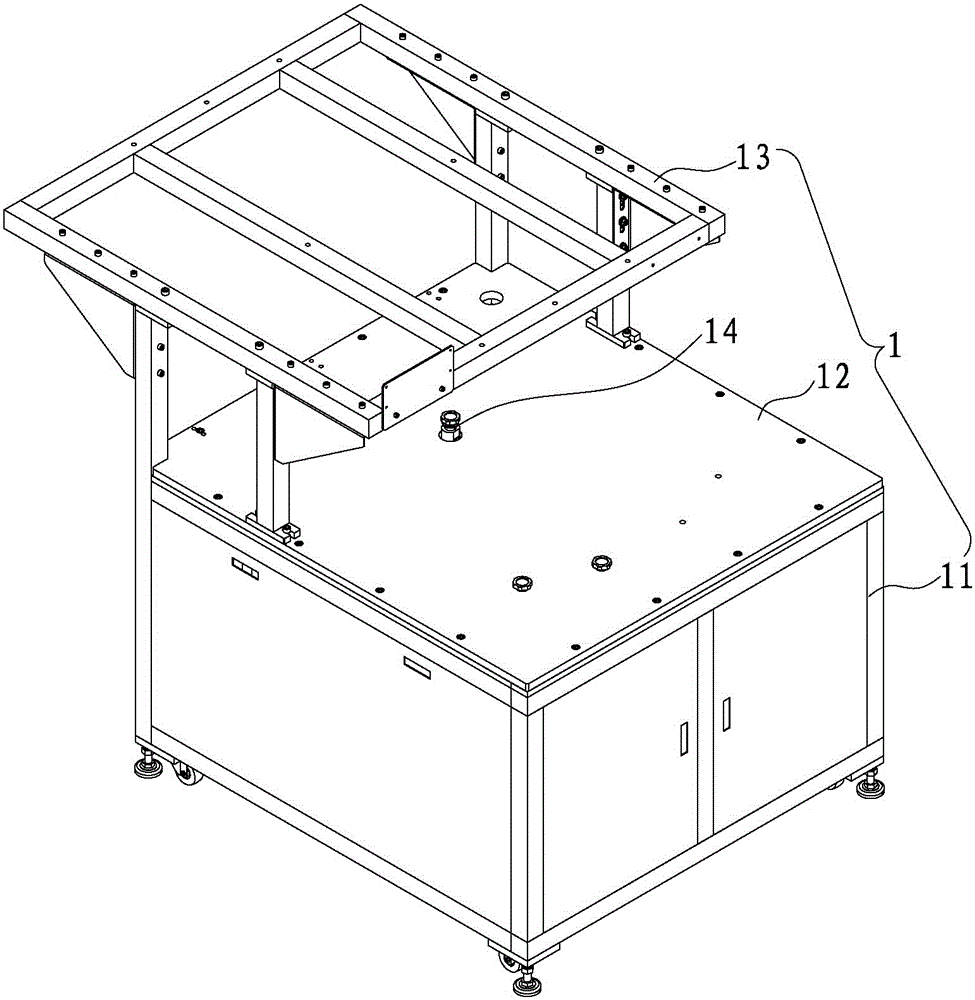

[0029] Such as figure 2 As shown, the frame assembly 1 includes a frame 11 , a working surface 12 , a top frame 1 , and a rotating shaft 14 . The worktable 12 and the top frame 13 are arranged at the middle and the top of the frame 11 respectively, and the rotating shaft 14 is arranged at the middle of the inner end of the worktable 12 .

[0030] Such as Figure 10 As shown, the outer end of the cartridge bracket 2 is provided with an arc-shaped groove 21 , and the inner end is provided with a hinged hole 22 .

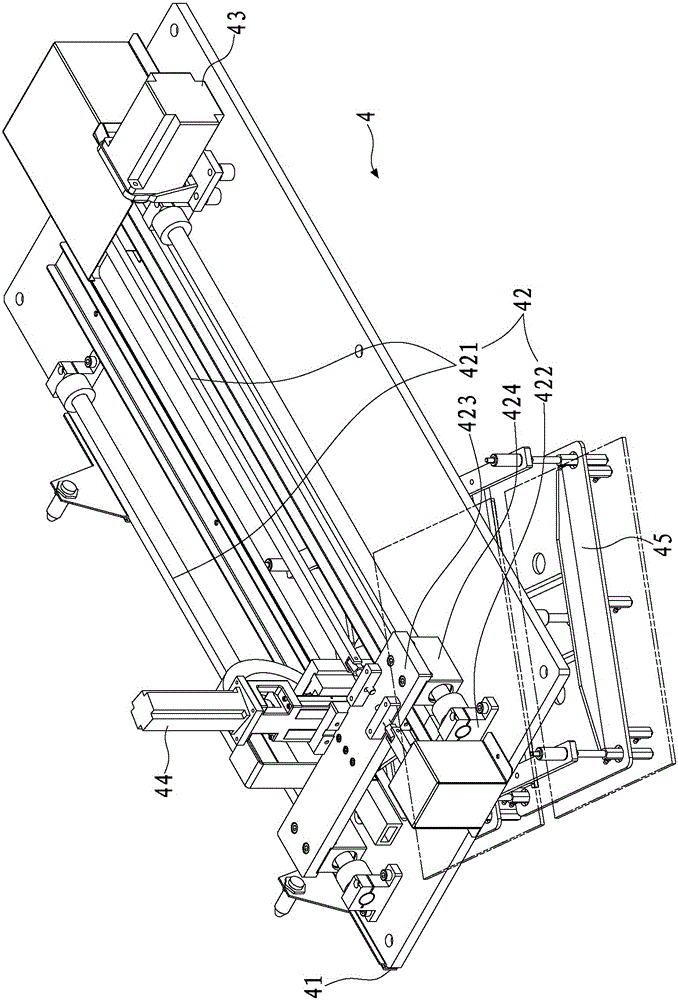

[0031] Such as figure 1 , figure 2 As shown, the middle part of the inner end of the magazine bracket 2 passes through the hinged hole 22 (as Figure 10 shown) is hinged on the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com