Mobile terminal and method for dissipating heat of mobile terminal

A mobile terminal and heat technology, applied in the direction of cooling/ventilation/heating transformation, telephone structure, etc., can solve the problems of hot panel, poor heat dissipation effect of stainless steel, poor consumer experience, etc., and achieve the effect of reducing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

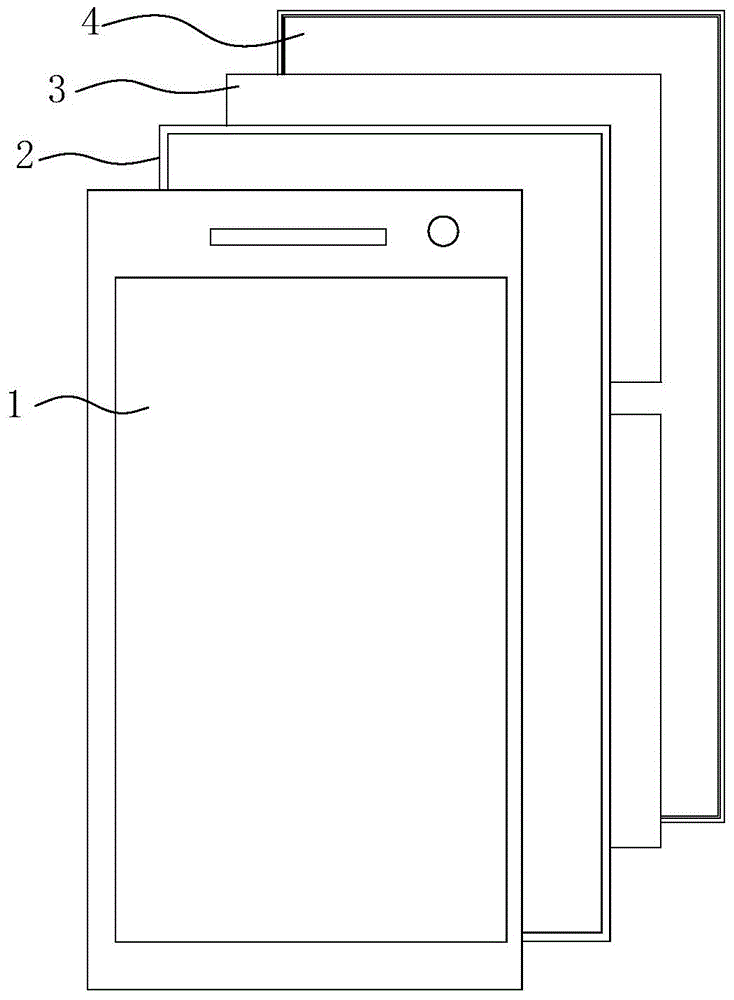

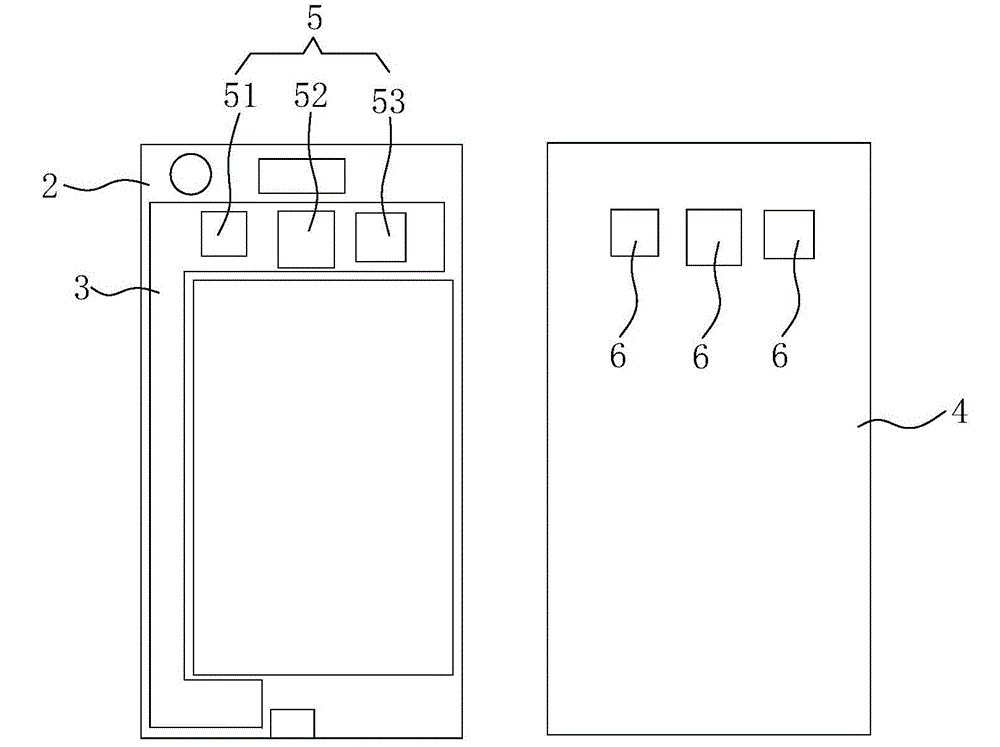

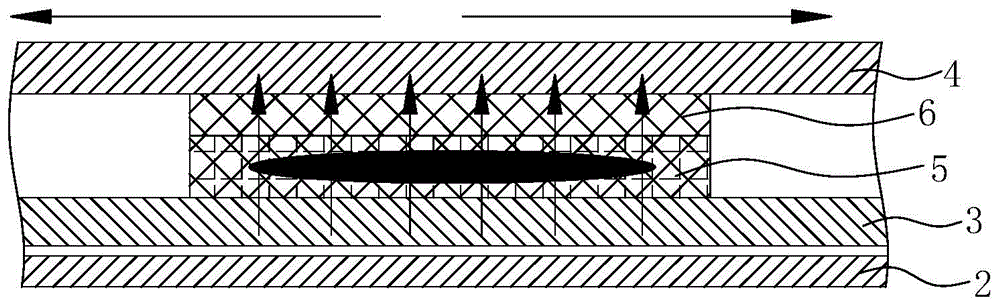

[0019] image 3 It is a schematic cross-sectional structural view of a mobile terminal provided by an embodiment of the present invention. Such as image 3 As shown, in this embodiment, the mobile terminal includes a main board 3 for installing a chip 5, a main board support member 2 and a rear case 4, and the rear case 4 is arranged on a side of the chip 5 away from the main board 3, A heat conduction layer 6 is provided between the chip 5 and the rear case 4 . By providing a heat conduction layer 6 between the chip 5 and the back shell 4, most of the heat of the mobile terminal can be transferred to the side away from the motherboard support member 2 through the heat conduction layer 6, that is, most of the heat is transferred to the back shell 4 to reduce heat dissipation. The heat transferred...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com