Food processing device and control method thereof

A technology of a food processing device and a control method, applied in the field of food processing, can solve the problems of inability to control the weight and shape of rice balls well, inconvenience in mass production, inconvenience in packaging and selling, etc. , the effect of eliminating health problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

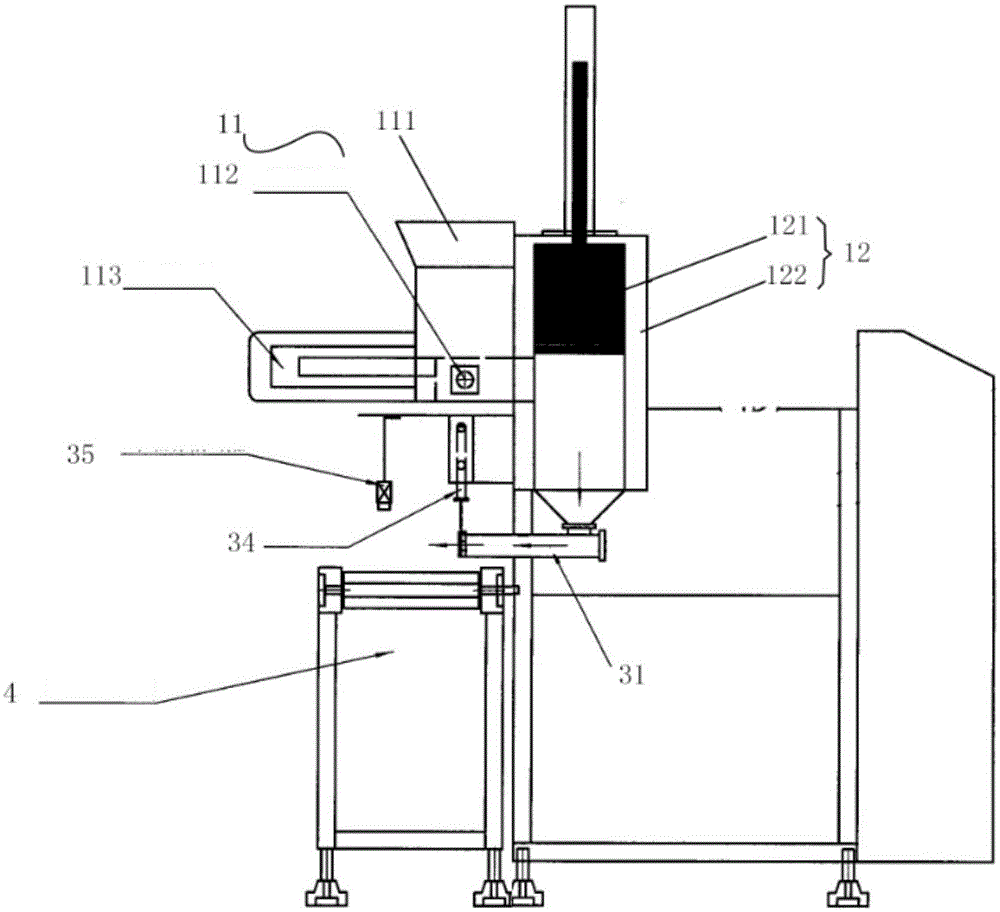

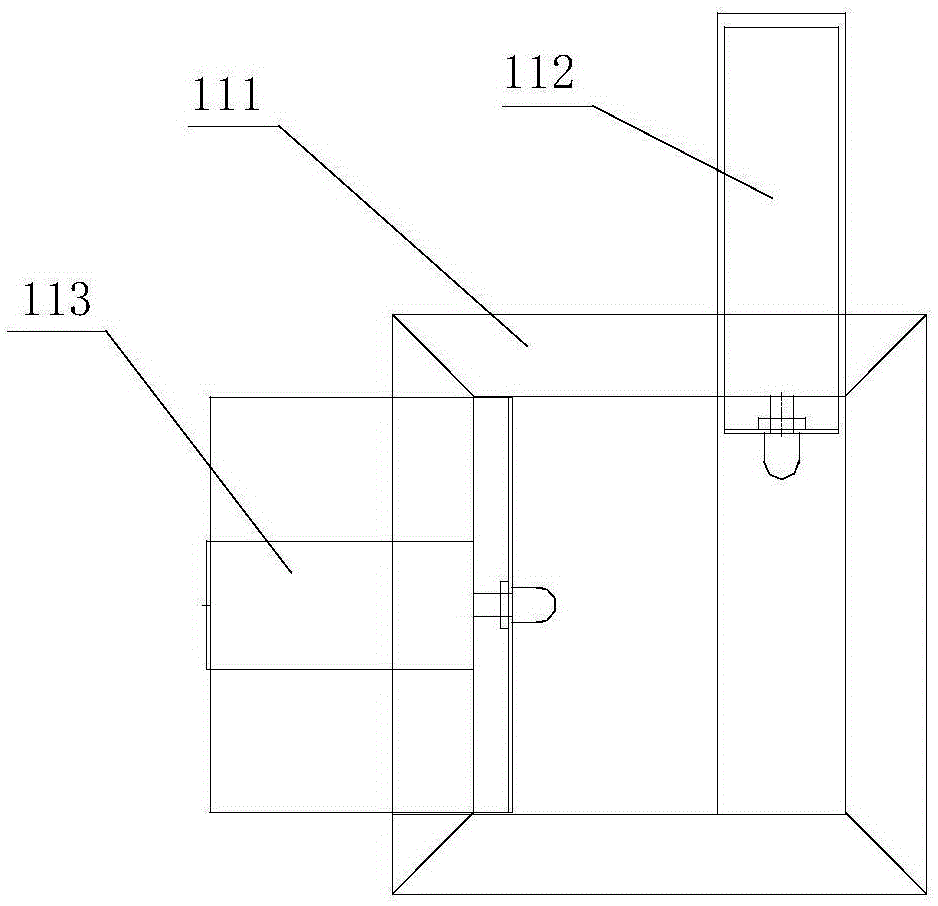

[0034] Such as figure 1 Shown, the molding device that makes instant food comprises main material conveying device 11, main material extruding device 12, main material forming device and control device, the outlet of described main material conveying device 11 is sealed with the entrance of main material extruding device 12 Fixed connection, the outlet of the main material extruding device 12 is sealed and fixedly connected with the inlet of the main material forming device, the main material forming device is a first pipeline 31 with one end closed, and the side wall of the first pipeline 31 It is sealed and fixedly connected with the outlet of the main material extruding device 12, and the control device is connected with the main material conveying device and the main material extruding device, and is used to control the flow of the main material conveying device and the main material extruding device. run.

[0035] The working process of the device described in Embodiment...

Embodiment 2

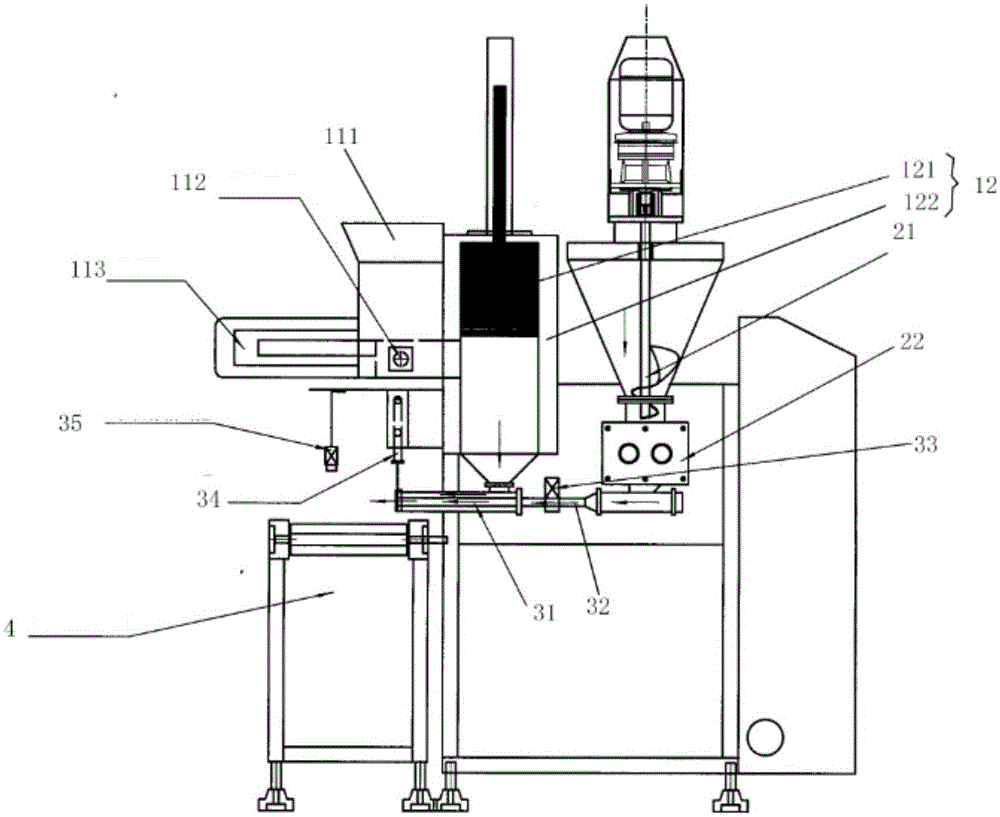

[0038] Such as figure 2 and Figure 4 As shown, on the basis of Embodiment 1, Embodiment 2 also includes a filling material conveying device 21, a filling material extruding device 22 and a filling material forming device, and the outlet of the filling material conveying device 21 is connected to the The inlet of the device 22 is sealed and fixedly connected, and the outlet of the stuffing extruding device 22 is sealed and fixedly connected with the inlet of the stuffing forming device. A second pipe 32 with an outer diameter smaller than the inner diameter of the first pipe 31, one end of the second pipe 32 is located axially inside the opening end of the first pipe 31, and the other end is located at the closed end 311 of the first pipe 31 The axially outer side is sealed and fixedly connected with the outlet of the stuffing extruding device 22 , and the closed end 311 of the first pipeline 31 is sealed and fixedly connected with the second pipeline 32 .

[0039] The work...

Embodiment 3

[0055] The present invention also provides a control method of a food processing device. The food processing device includes a main material conveying device, a main material extruding device, a main material forming device and a control device, such as Figure 6 shown, including the following steps:

[0056] S101, acquiring the information that the main material extruding device has run to the initial extruding position;

[0057] In step S101, the main material extruding device performs a reciprocating extrusion movement, so before extrusion, it needs to run to the initial position, and wait for the main material to be sent into the main material extruding device by the main material conveying device.

[0058] S102, the control device controls the operation and timing of the main material conveying device, and the main material conveying device sends the main material into the main material extruding device;

[0059] In step S102, once the main material extruding device reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com