Multi-tape gluing device for paper tube machine

A gluing device and paper tube machine technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of high technology and production experience requirements, affecting the production quality of paper tubes, uneven bonding of paper tubes, etc. , to achieve the effect of low work experience requirement, simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

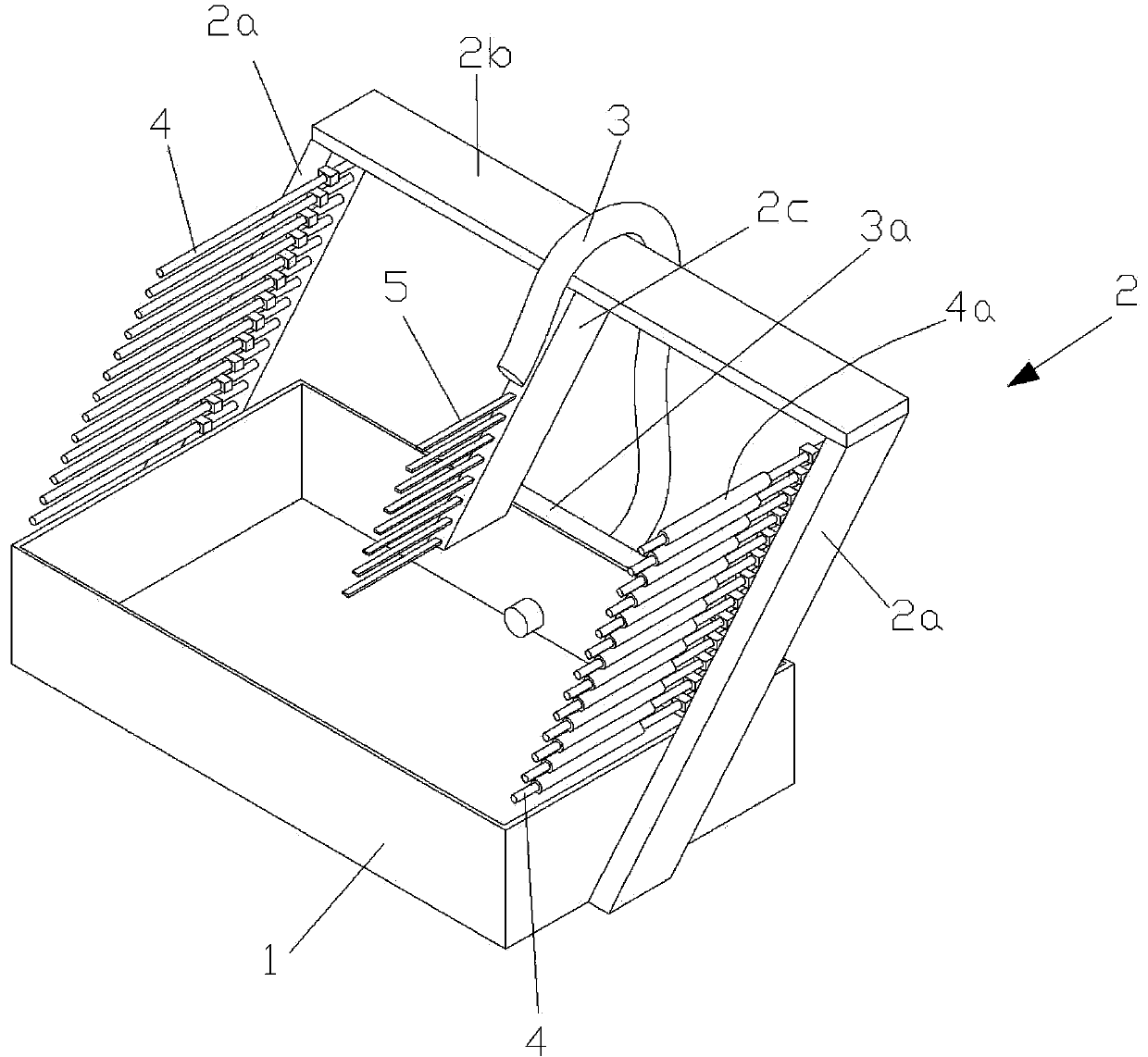

[0014] Such as figure 1 As shown, the multi-tape gluing device of the paper tube machine includes a rectangular glue pool 1, and a frame 2 is straddled above the glue pool 1.

[0015] The frame 2 includes two brackets 2a symmetrically connected to the outer wall of the glue pool 1, and one end of the brackets 2a is inclined to the side of the glue pool 1, and a beam 2b is erected on the top of the two brackets 2a.

[0016] The glue spray pipe 3 is erected above the middle part of the beam 2b. One end of the glue spray pipe 3 communicates with the glue pool 1 through the pump body 3a, and the other end corresponds to the glue pool 1 downward.

[0017] Below the middle part of the crossbeam 2b, an extension 2c is provided downwards, one end of which has a certain distance from the glue pool, and the extension corresponds to the brackets 2a on both sides, and is arranged obliquely.

[0018] A group of paper rods 4 are respectively connected to the inner sides of the two brackets...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com