Control method for preventing tail flicking in steel-strip precision rolling

A control method and strip steel technology, applied in the direction of rolling force/roll gap control, metal rolling, metal rolling, etc., can solve the problem that strip steel tailing cannot be fundamentally prevented

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

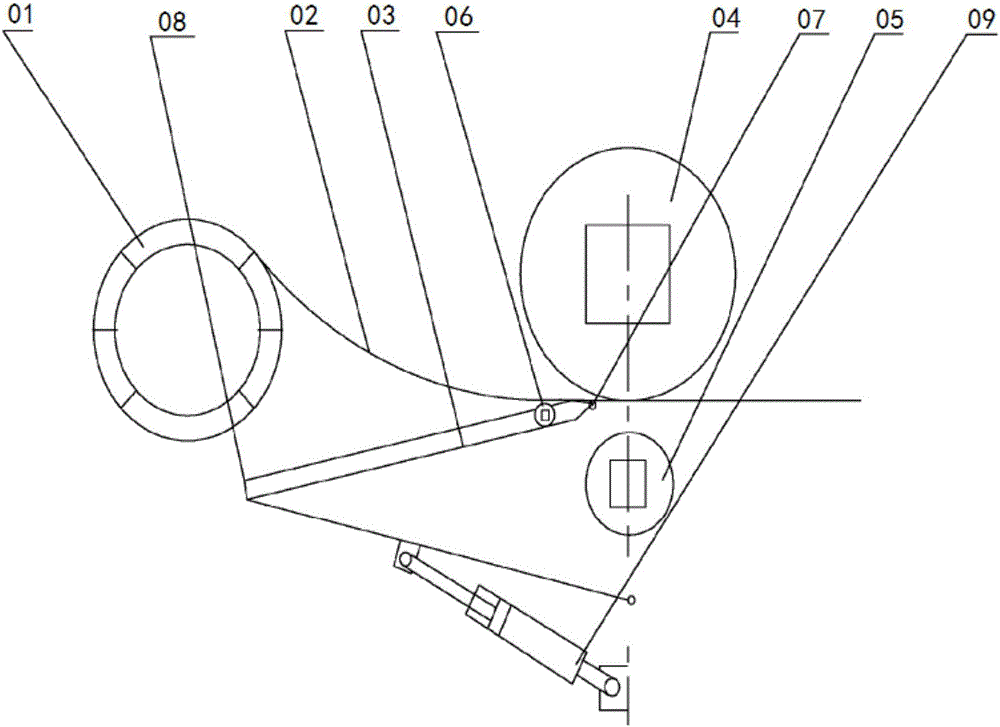

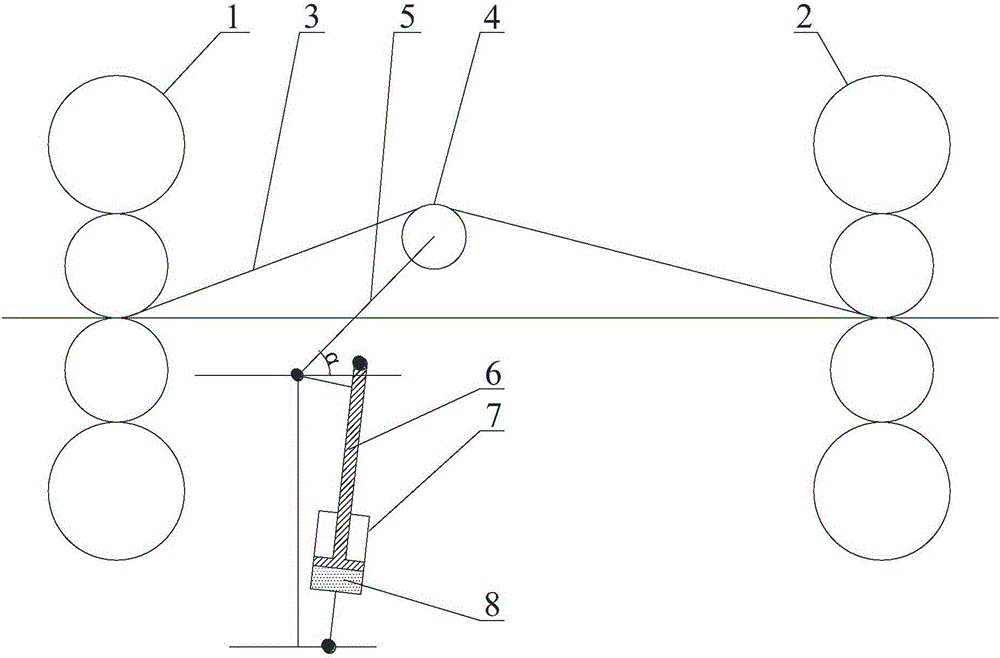

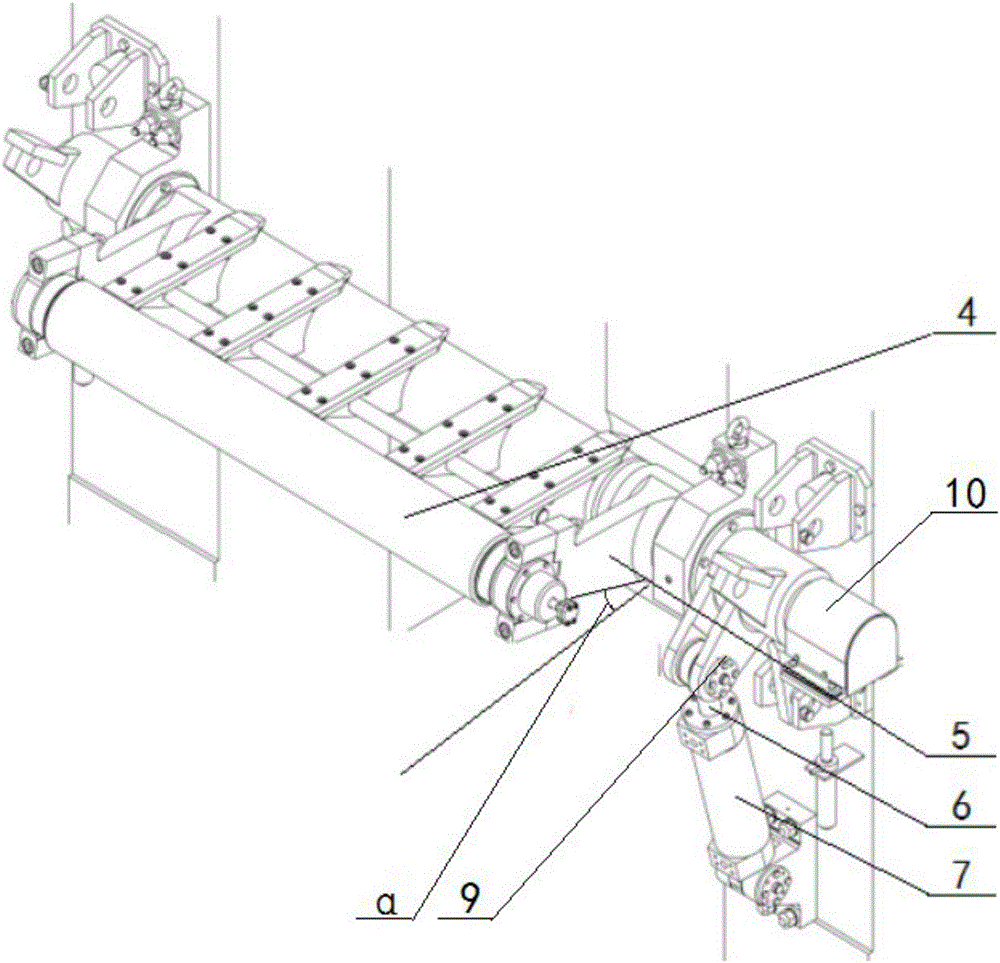

[0048] In the control method for preventing tailing in the strip finish rolling provided by the present invention, the rolling train of the strip comprises a multi-stand rolling mill, see the attached Figure 4 , in this embodiment, the number of rolling mills is 7, and loopers and angle control components are respectively arranged between adjacent two rolling mills. In this embodiment, the loopers are respectively 1# looper, 2# looper, and 3# Looper, 4# Looper, 5# Looper, 6# Looper, see attached figure 2 , taking the looper arranged between the first rolling mill 1 and the second rolling mill 2 as an example, the looper includes a looper roller 4, a looper support arm 5, and the angle control assembly is used to control the angle of the looper support arm 5, When the strip 3 passes between two adjacent rolling mills, the looper roll 4 is used to support the strip 3 between the adjacent two rolling mills;

[0049] See attached Figure 4 And attached Figure 5 , the method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com