Nail puller for wooden formwork of building external wall

A technology for wood boards and nails, which is applied in the field of external wall wood mold recycling, can solve the problems of steel nails being unfavorable for the fixed use of wood boards, easy to scratch, and nail penetration, etc., so as to shorten the pull-out time, increase the service life, and reduce the force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

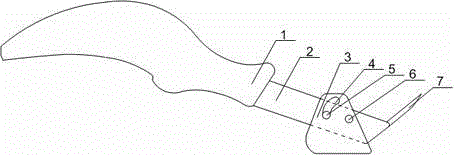

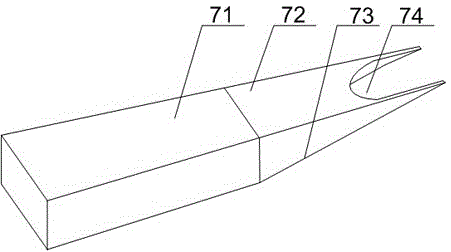

[0020] like figure 1 and figure 2 As shown, this embodiment includes a U-shaped bracket 3, and a handle section 1 and a support section 2 that are connected to each other. The support section 2 is rotated on the bracket 3 through a hinge shaft 6. Nail piece 7, described nail pulling piece 7 is made up of connecting section 71 and nail pulling section 72 connected with each other, and described nail pulling section 72 upper surface is horizontal plane and its lower surface is inclined surface 73, and described horizontal plane and inclined surface 73 An acute angle is formed between them, and an arc-shaped groove for the steel nail body to pass is opened at the end of the nail pulling section 72 along its end surface pointing to the direction of the connecting section 71 .

[0021] The upper surface of the nail-pulling section 72 is a horizontal plane, and the lower surface is an inclined surface 73, and an arc-shaped groove is provided on the nail-pulling section 72 along it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com