Full-automatic deburring device

A deburring, fully automatic technology, applied in the field of injection molding product processing, can solve the problems of low operation efficiency, time-consuming and laborious, insufficient precision, etc., and achieve the effect of simple operation mode, reduced production cost, and high removal accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in more detail below in conjunction with the accompanying drawings and embodiments.

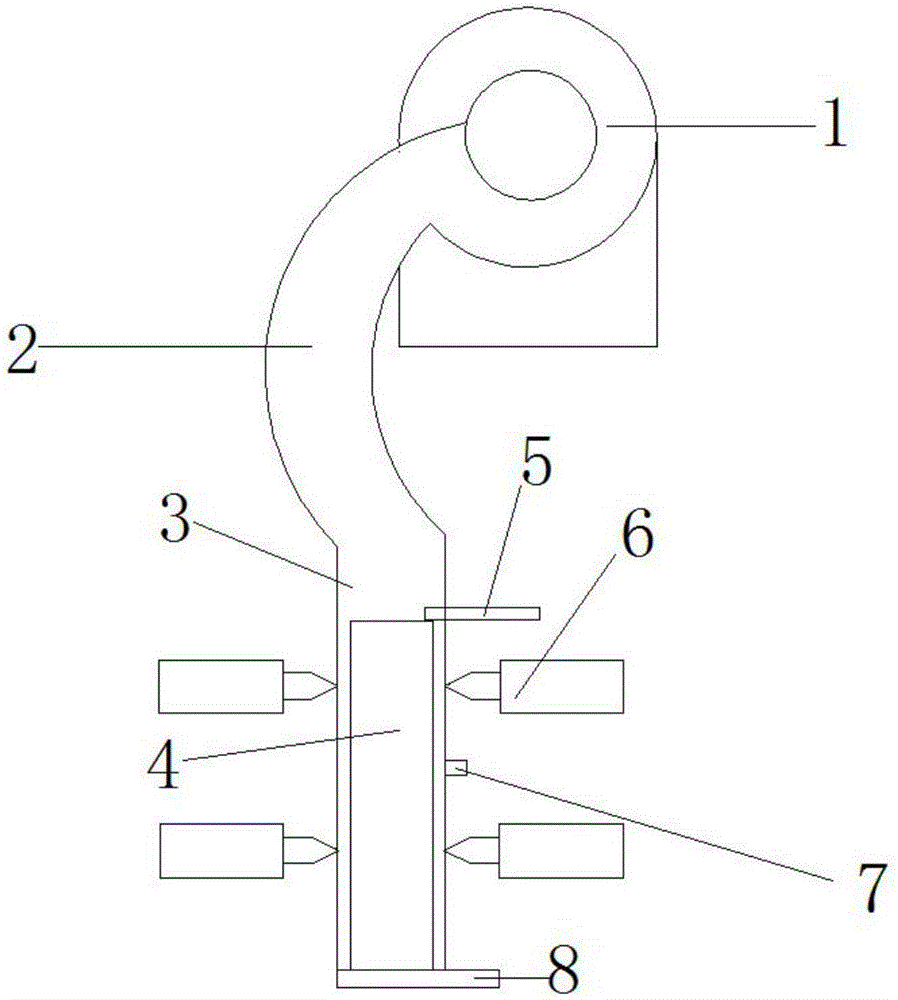

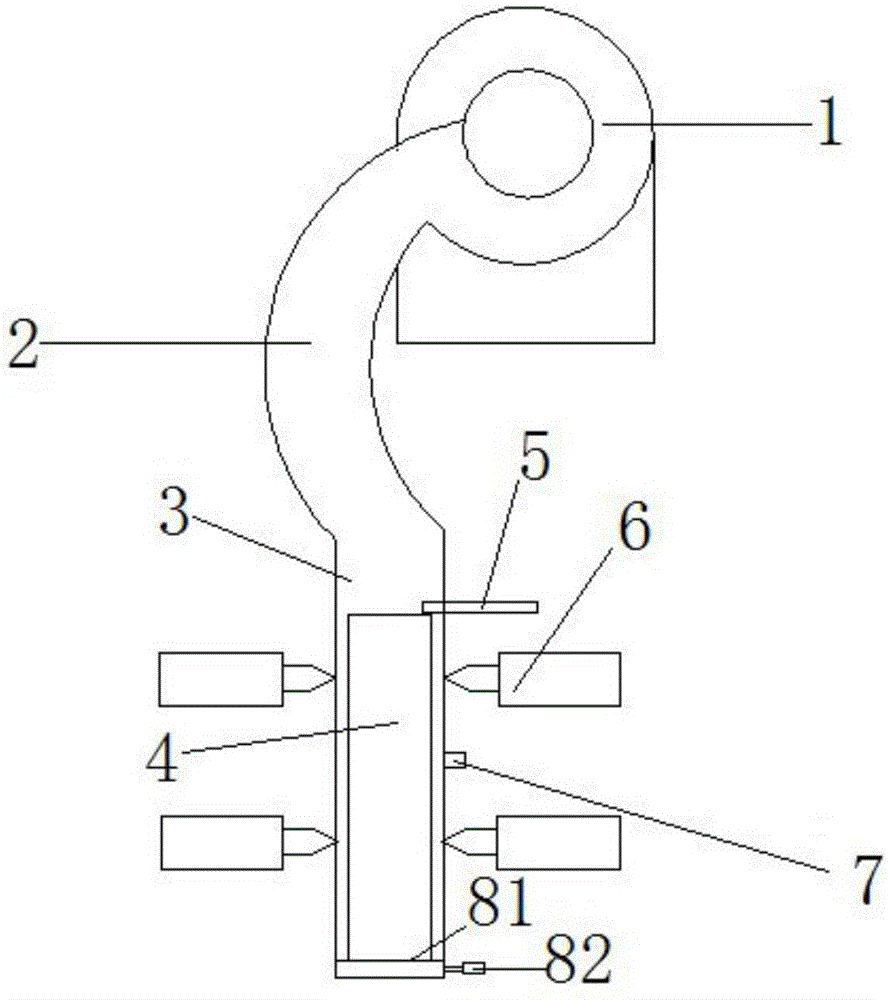

[0014] like figure 1 As shown, a fully automatic deburring device includes a frame and a controller installed on the frame, a photoelectric sensor 7, a front limit device 5, a rear limit device 8, a punch cylinder 6, a vibrating plate 1, Conveying track 2, conveying line 3, described vibrating plate 1, conveying track 2, conveying line 3 are sequentially connected, and described conveying line 3 bottom is provided with product positioning mold 4, and described photoelectric sensor 7 is installed on the product positioning mold 4, both sides of the conveying line 3 are equipped with punching needle cylinders 6, and the front limiting device 5 and the rear limiting device 8 are respectively installed at the front and rear ends of the product positioning mold 4. Photoelectric sensor 7, front limiter 5, rear limiter 8, punch cylinder 6 are all conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com