Hydraulic wheel anti-skid device capable of automatically stretching out

An anti-skid device and wheel technology, applied in the direction of wheels, wheel accessories, vehicle parts, etc., can solve the problems of aggravated tire wear, slippery road surface, serious traffic accidents, etc., and achieve the effect of increasing friction and preventing skidding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

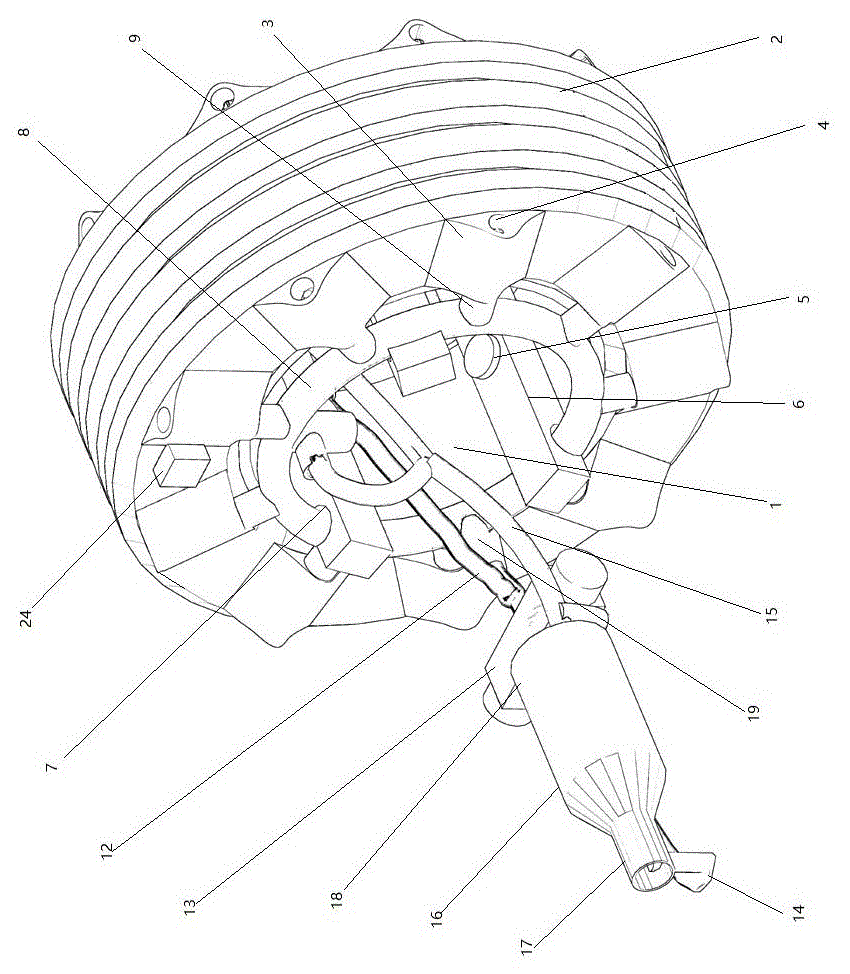

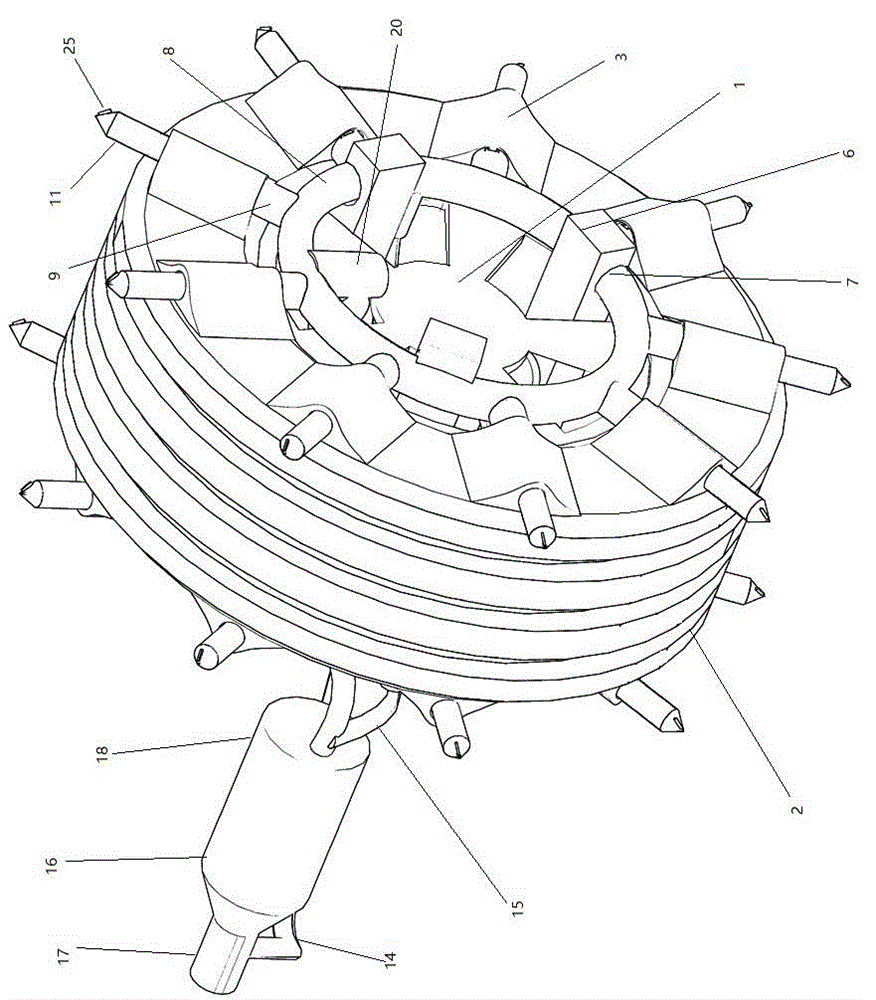

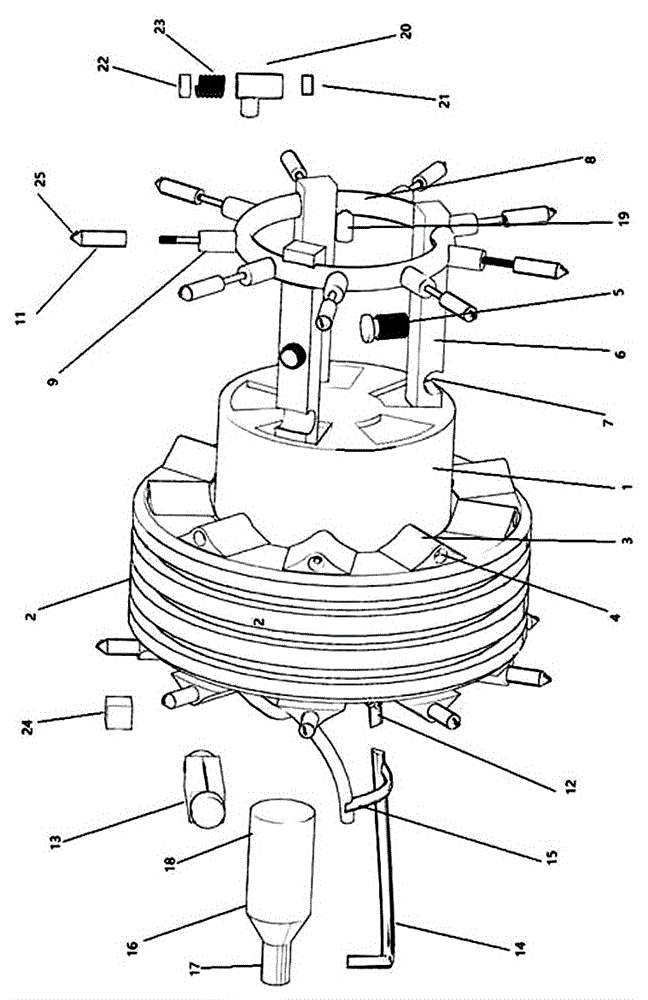

[0016] Such as figure 1 , figure 2 , image 3 As shown, the hydraulic self-protruding wheel anti-skid device includes a wheel hub 1; a tire 2 is installed on the outside of the wheel hub 1; evenly distributed arched protrusions 3 are arranged on both sides of the tire 2; the middle position of the arched protrusion 3 is in the The tire 2 is provided with a through hole 4 in the radial direction; the inner side of the hub 1 is fixedly connected with evenly distributed fixing frames 6 through screws 5; both ends of each fixing frame 6 are provided with limiting grooves 7; the limiting grooves on each side 7 An annular hydraulic pipe 8 is fitted on both sides of the hub 1; the outer sides of the two hydraulic pipes 8 are radially connected to the radial direction of the tire 2, and there are uniformly distributed single-rod piston hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com