Embedded scraper transporter head assembly having scraper chain automatic compensation function

A technology of buried scraper conveyor and scraper chain, which is applied in the field of head assembly of buried scraper conveyor, which can solve problems such as unreliability, chain skipping, and increased friction, so as to reduce working intensity and ensure long-term Safety and life-prolonging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

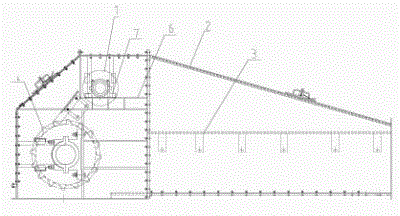

[0022] like figure 2 As shown, a head assembly of buried scraper conveyor with automatic compensation function of scraper chain, including head shell 2, which is equipped with upper guide rail 3, head wheel 4, chain knife 5. The chain supporting knife 5 is installed close to the rear of the head wheel 4 to support the chain and smoothly enter the upper guide rail 3, and the upper guide rail 3 is smoothly connected with the chain supporting knife 5. Supporting roller 1 is installed in the head shell 2, and described supporting roller 1 is fixed on the supporting roller frame 6, and supporting roller frame 6 is positioned at head wheel 4 tops, and supporting roller 1 is close to wheel 4. The supporting roller 1 is fixed on the supporting roller frame 6 by connecting bolts 7 .

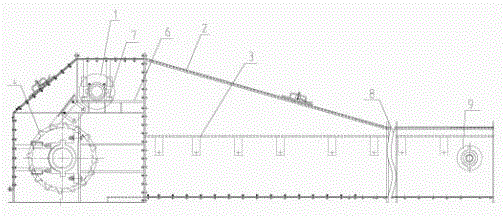

[0023] A kind of buried scraper conveyor adopting the head assembly of the present invention, such as image 3 As shown, the head assembly is connected to the middle section 8, and the middle section 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com