Automatic grabbing device and grabbing method for soft board

A technology for grabbing devices and soft boards, which is applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems of high labor costs, low production efficiency, and large volume, and achieve the effect of reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

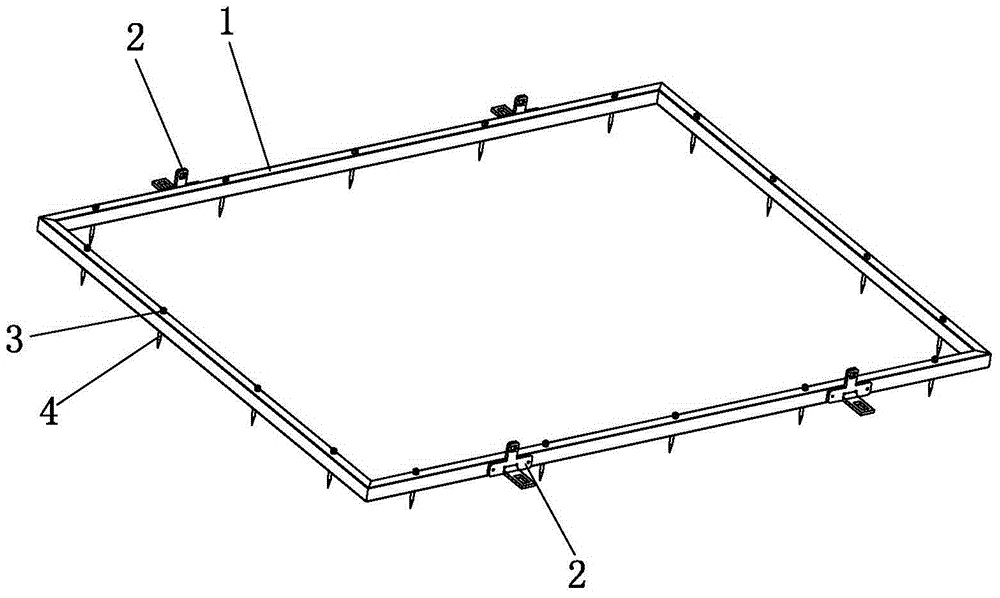

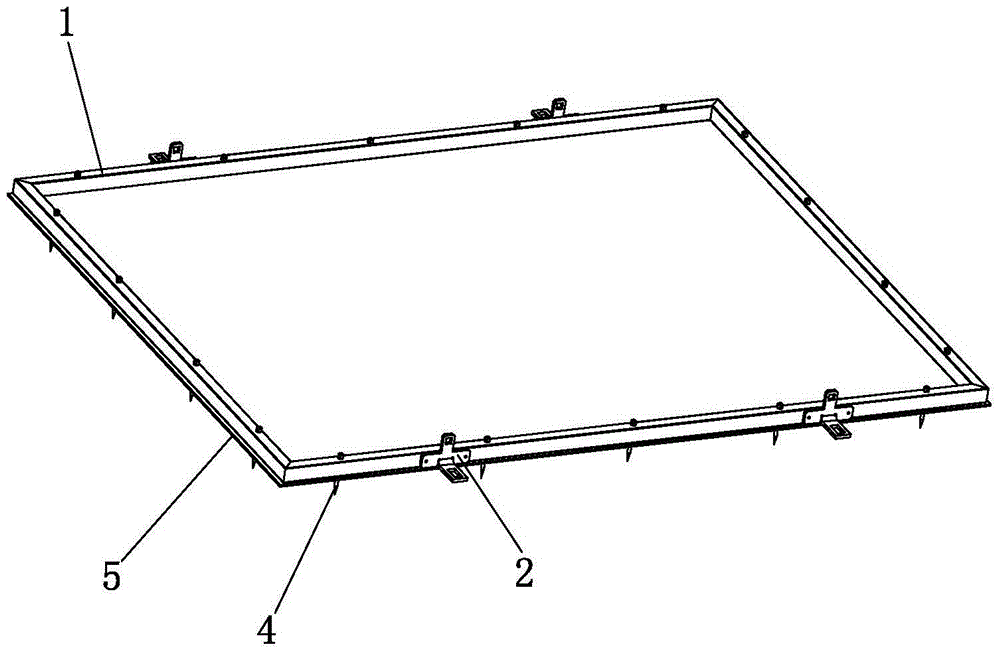

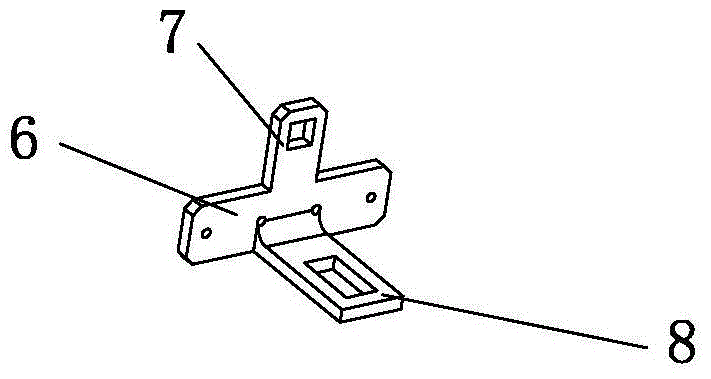

[0020] Such as Figure 1 to Figure 4 As shown, the automatic grabbing device for soft boards of the present invention (referred to as "grabbing device") includes a nail frame 1, a straight nail 4 and a positioning seat 2, and the upper end of the straight nail 4 is provided with an external thread, and the middle surface is rough , the bottom end is sharp, the middle part of the straight nail 4 can be knurled to make the surface rough, and the surface of the middle part of the straight nail 4 is rough so that the soft board is not easy to fall when it is inserted into the soft board. A plurality of straight nails 4 are installed on the nail frame 1 , the straight nails 4 vertically penetrate the nail frame 1 , and the rough middle part and the sharp bottom end of the straight nails 4 protrude below the nail frame 1 . The upper end of the straight nail 4 is connected with a nut 3 for fixing the straight nail 4 on the nail frame 1 . The straight nails 4 are arranged non-uniform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com