Multiflora natural fiber jacquard loom

A natural fiber, jacquard loom technology, applied in the direction of jacquard, textile, textile and paper making, can solve the problems of inability to jacquard, complex, the height of the brown frame cannot meet the production requirements, etc., to increase economic benefits and improve product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

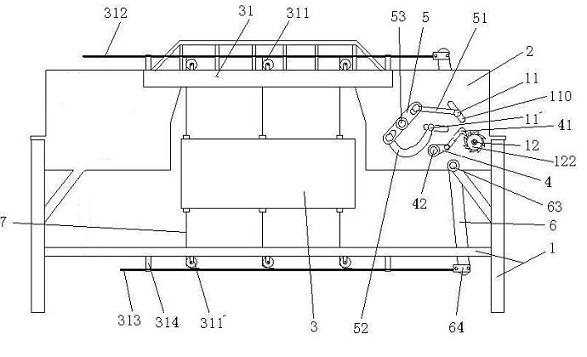

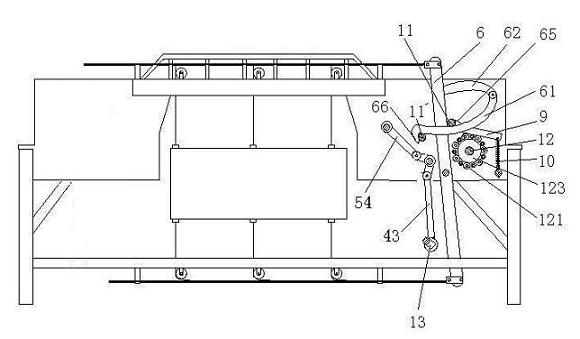

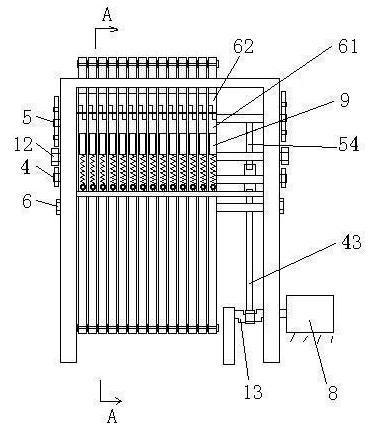

[0031] Such as figure 1 , 2 Shown, the present invention comprises frame 1 and the frame wallboard 2 of two ends thereof, also comprises heald frame 3, drives the power unit that heald frame 3 moves up and down, further comprises first, second, the 3rd swing arm 4, 5,6.

[0032] still as figure 1 , 2 As shown, the two ends of the swing arm shafts 42, 53 of the first and second swing arms pass through the frame wallboard 2 and are respectively fixedly connected with the first and second swing arms 4, 5. The swing arm shafts 42, 53 It is movably connected to the frame wallboard 2. Both ends of the swing arm shaft 63 of the third swing arm 6 are fixedly connected to the frame wallboard 2 , and the third swing arm 6 is located in the frame wallboard 2 and is movably connected to the swing arm shaft 63 .

[0033] The upper and lower ends of the third swing arm 6 are provided with drag cables 7, respectively connected to the upper and lower frames of the heald frame 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com