An anti-oxidation high-temperature infrared radiation ceramic coating and its preparation method and application

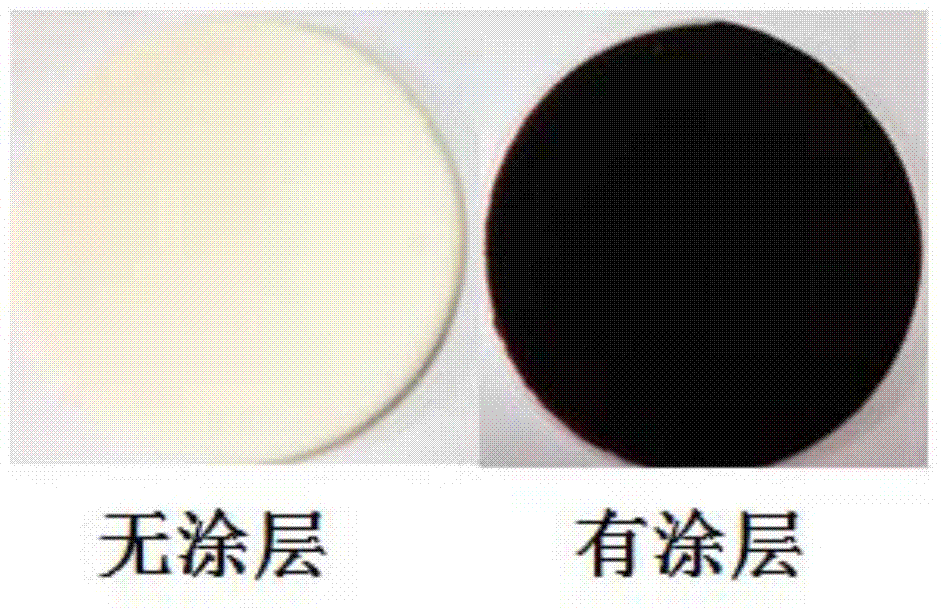

A ceramic coating, high-temperature infrared technology, applied in the direction of coating, etc., can solve the problems of unstable emissivity, shedding, low infrared radiation rate, etc., and achieve the effect of excellent oxidation resistance, excellent thermal shock resistance and high emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1) Preparation of paint

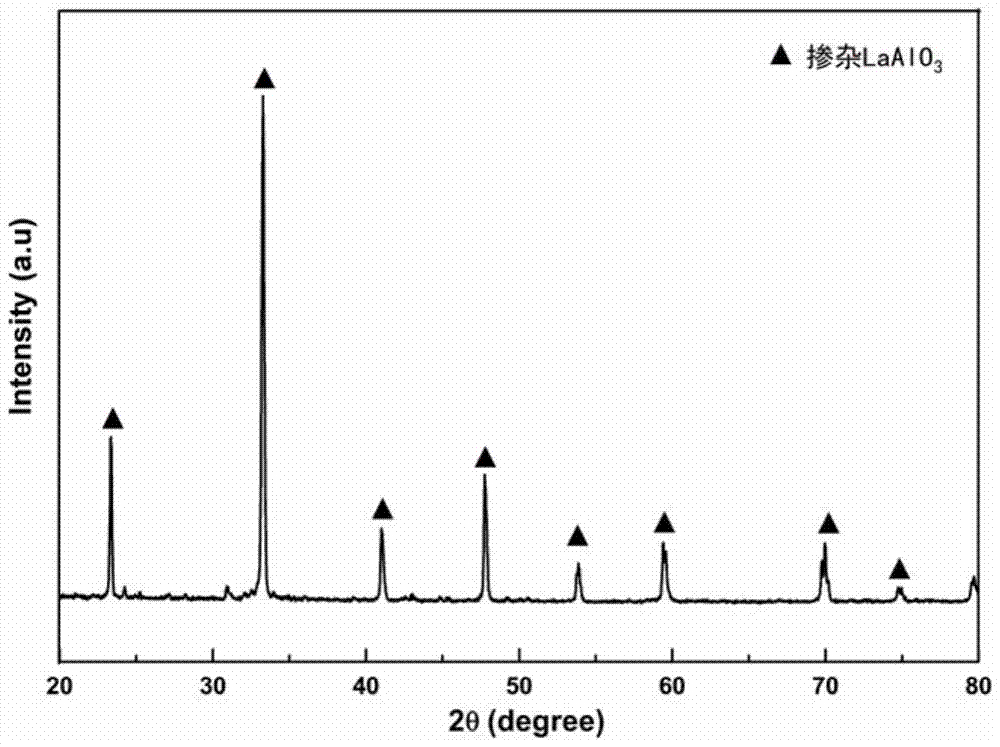

[0039] Calcium-chromium ion-doped lanthanum aluminate was prepared according to the method of the patent (CN2015101198851); 1 kg of calcium-chromium ion-doped lanthanum aluminate was mixed with 2000 ml of absolute alcohol, and star-shaped ball milled for 2 hours; after ball milling, it was dried to obtain 325 mesh Radiation base material of particle size; 1 kg of said radiation base material, 150 g of ultrafine nano silicon dioxide, 15 g of polyacrylic acid with an average degree of polymerization of 3000, 50 g of polyvinyl alcohol with an average degree of polymerization of 1750 and 1.66 kg of water are mixed and stirred , put into a star ball mill and mix at high speed for 2 hours. Made into anti-oxidation high temperature coating.

[0040] 2) Use of paint

[0041] Send the anti-oxidation high-temperature paint into the F-75 spray gun. Under the condition of 0.4MPa pressure, the spraying distance is 20cm, and the spraying time is 5 seconds....

Embodiment 2

[0044] 1) Preparation of paint

[0045] Calcium-chromium ion-doped lanthanum aluminate was prepared according to the method of the patent (CN2015101198851); 1 kg of calcium-chromium ion-doped lanthanum aluminate was mixed with 5000 ml of anhydrous alcohol, and star-shaped ball milled for 2 hours; after ball milling, it was dried to obtain 325 mesh The radiation base material of particle size; the said radiation base material of 1kg, the superfine nano silicon dioxide of 50g, the polyacrylic acid that the average polymerization degree of 15g is 3000, the polyvinyl alcohol and the water of 1.0kg that the average polymerization degree of 50g is 1750 Mix and stir, put into a star ball mill and mix at high speed for 2 hours. Made into anti-oxidation high temperature coating.

[0046] 2) Use of paint

[0047] Send the anti-oxidation high-temperature paint into the F-75 spray gun. Under the condition of 0.4MPa pressure, the spraying distance is 20cm, and the spraying time is 5 seco...

Embodiment 3

[0050] 1) Preparation of paint

[0051] Prepare calcium-chromium ion-doped lanthanum aluminate according to the method of the patent (CN2015101198851); mix 1kg of calcium-chromium ion-doped lanthanum aluminate with 3000ml of absolute alcohol, star ball mill for 2 hours; dry after ball milling to obtain 325 mesh Radiation base material of particle size; 1kg of the radiation base material, 300g of silica sol, 15g of polyacrylic acid with an average degree of polymerization of 4500, 50g of polyvinyl alcohol with an average degree of polymerization of 1000 and 560g of water are mixed and stirred, and put into a star shape The ball mill was mixed at high speed for 2 hours. Made into anti-oxidation high temperature coating.

[0052] 2) Use of paint

[0053] Send the anti-oxidation high-temperature paint into the W77 spray gun. Under the condition of 0.4MPa pressure, the spraying distance is 20cm, the spraying time is 5 seconds, and it is dried for 24 hours after spraying. Put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com