Cotton sliver doubling machine auxiliary winding device

A cotton spinning sliver, auxiliary roll technology, applied in winding mechanism, textile and papermaking, fiber processing and other directions, can solve the problems of sticky roll, sticky layer, wool roll, etc., to prevent abnormal delamination, improve weight unevenness , The effect of improving product quality and output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

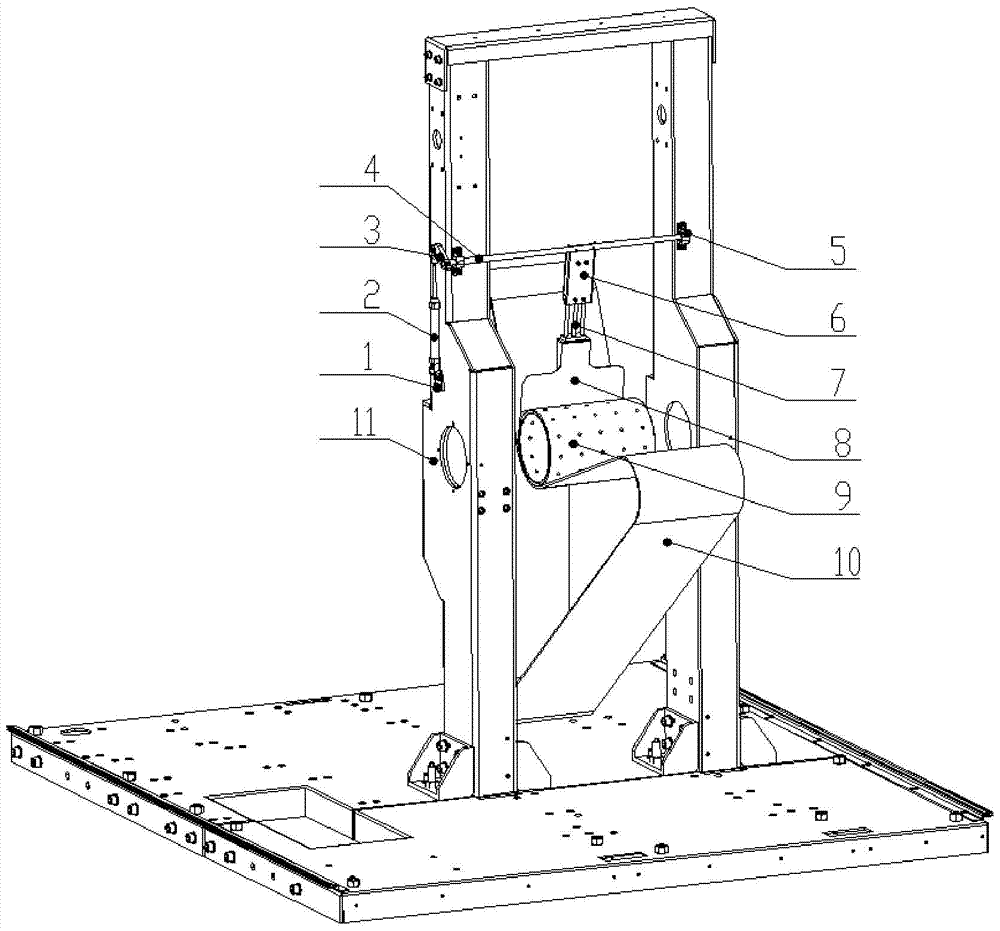

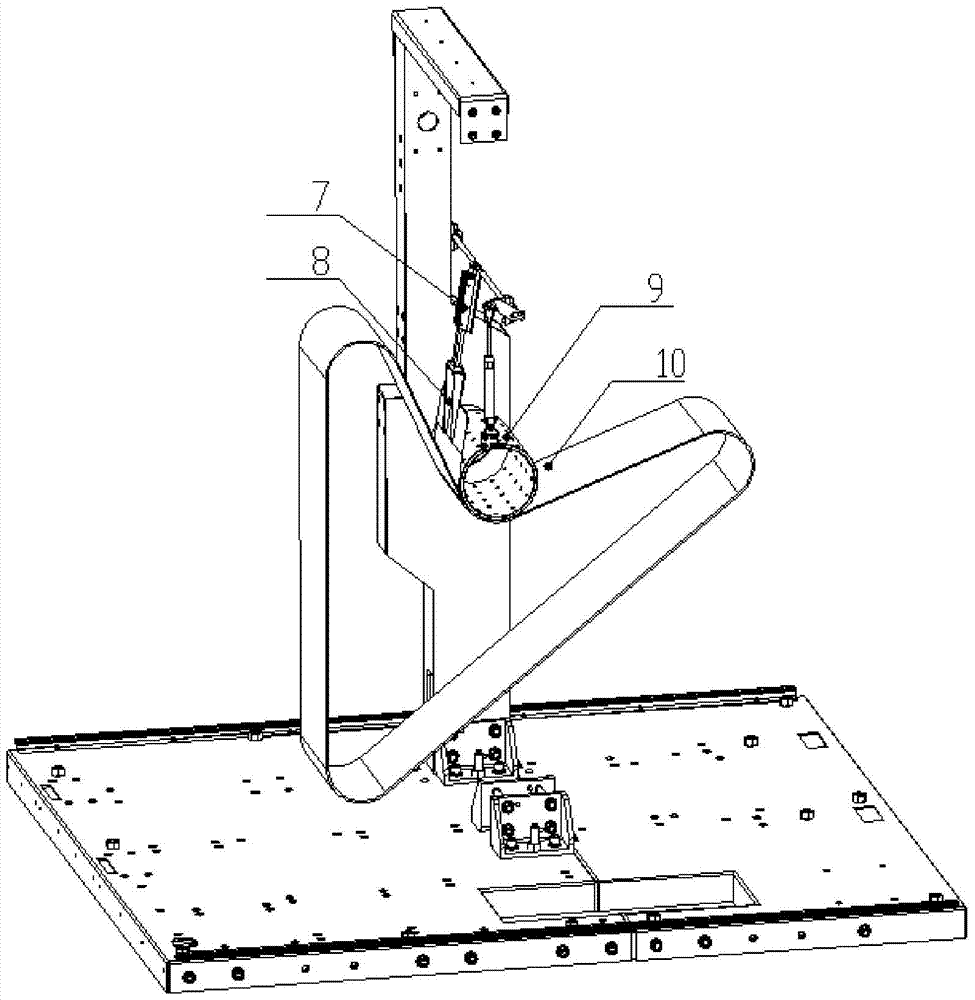

[0022] Embodiment: an auxiliary winding device for a cotton sliver doubling machine, including a rotating shaft 4, a lap pressing device, a rotating drive device and a control system. One end of the roll pressing device is fixedly positioned with the outer surface of the rotating shaft 4, and the other end can just extend into the gap between the cotton roll 12 and the winding belt 10 at the front end of the winding direction, and the other end of the cotton roll pressing device can just touch the cotton roll. On the surface of the roll 12, the rotating drive device drives the rotating shaft 4 to rotate, and the control system controls the operation of the rotating driving device. During the production process, the control system controls the action of the rotating driving device according to the diameter change of the cotton roll 12, and then drives the rotating shaft 4 clockwise or counterclockwise. The reciprocating rotation of the cotton lap 12 during production increases, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com