A deacidification method and deacidification device

A deacidification method and deacidification technology, applied in the field of deacidification, can solve the problems of relatively stringent requirements for instruments and equipment, limitations in industrial application, and inconspicuous deacidification effect, and achieve sample deformation, uniform deacidification effect, and enhanced mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

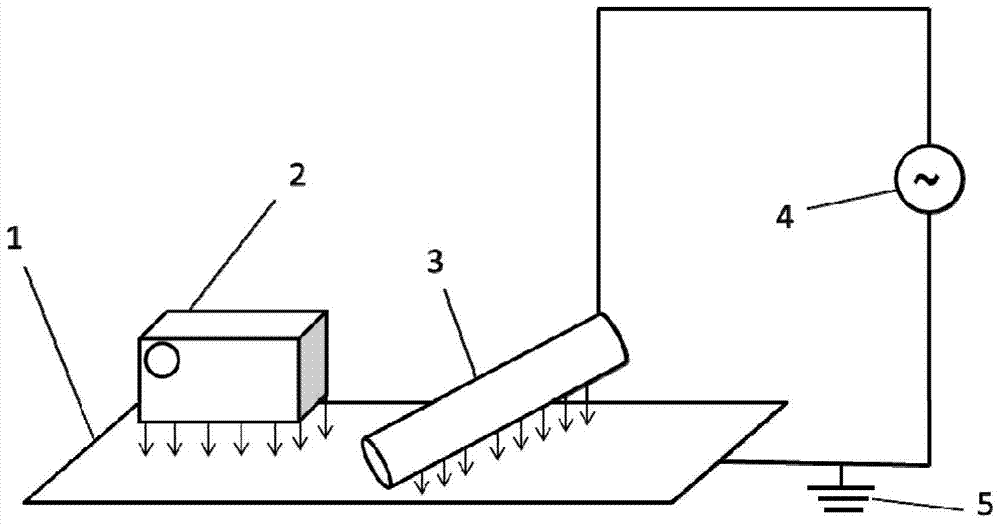

Image

Examples

Embodiment 1

[0056] (1) Spread the paper to be deacidified on the movable table;

[0057] (2) Inject Mg(HCO pH=8.2) into the deacidification agent supply device 3 ) 2 Aqueous solution, and atomization treatment, spray the deacidification agent after atomization on the paper to be deacidified at a flow rate of 100mL / h, and the spraying time is 30s;

[0058] (3) Turn on the pulse power supply, adjust the current to 0.1A, and adjust the voltage to 75V to form a stable blue-violet linear filamentous plasma, and use the plasma to perform a full-range moving scan on the paper, and the scan time is 1min to complete the stripping process. Acid treatment.

[0059] The pH value and tensile strength of the deacidified paper were tested according to standard procedures to quantify the deacidification effect and determine the effect of deacidification on paper properties.

[0060] After deacidification treatment, the acidified paper was converted from acid (pH=6.0) to alkaline (pH=7.9), and the tens...

Embodiment 2

[0062] (1) Spread the paper to be deacidified on the movable table;

[0063] (2) Inject Mg(HCO pH=8.2) into the deacidification agent supply device 3 ) 2 Aqueous solution, and atomization treatment, spray the deacidification agent after atomization on the paper to be deacidified at a flow rate of 100mL / h, and the spraying time is 45s;

[0064] (3) Turn on the pulse power supply, adjust the current to 0.15A, and adjust the voltage to 75V to form a stable blue-violet linear filamentous plasma, and use the plasma to perform a full-range moving scan on the paper, the scan time is 1min, and the removal of the paper is completed. Acid treatment.

[0065] The pH value and tensile strength of the deacidified paper were tested according to standard procedures to quantify the deacidification effect and determine the effect of deacidification on paper properties.

[0066] After deacidification, the acidified paper was converted from acid (pH=6.2) to alkaline (pH=7.5), and the tensile ...

Embodiment 3

[0068] (1) Spread the paper to be deacidified on the movable table;

[0069] (2) Inject Mg(HCO pH=8.2) into the deacidification agent supply device 3 ) 2 Aqueous solution, and atomization treatment, spray the deacidification agent after atomization on the paper to be deacidified at a flow rate of 100mL / h, and the spraying time is 1min;

[0070] (3) Turn on the pulse power supply, adjust the current to 0.25A, and adjust the voltage to 70V to form a stable blue-violet linear filamentous plasma, and use the plasma to perform a full-range moving scan on the paper, the scan time is 1min, and the stripping is completed. Acid treatment.

[0071] The pH value and tensile strength of the deacidified paper were tested according to standard procedures to quantify the deacidification effect and determine the effect of deacidification on paper properties.

[0072] After deacidification, the acidified paper was converted from acid (pH=6.6) to alkaline (pH=8.1), and the tensile strength w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com