Safety cone automatic retraction process

A safety cone, fully automatic technology, applied in the directions of roads, road signs, traffic signals, etc., can solve the problems of high cost, unfavorable promotion and application, complex structure, etc., to reduce the probability of secondary accidents, increase the scope of application, and increase the operation process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

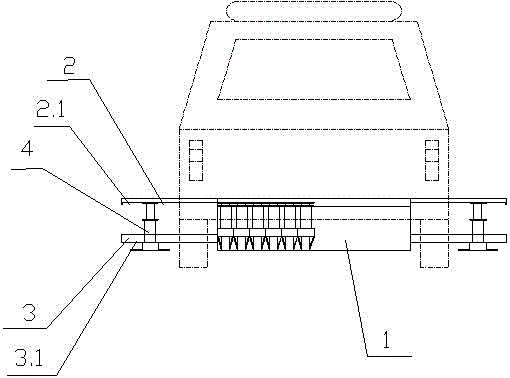

[0043] see Figure 1~9 , the present invention relates to a fully automatic retracting process for safety cones, the retracting process includes the following steps:

[0044] When spreading:

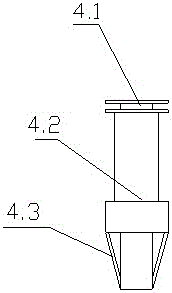

[0045] Step 1.1: The shift fork suction cup 2.1 on the translation rod 2 absorbs the inner cylinder 4.1 of the safety cone 4 on the storage rack 1, and the lifting suction cup 3.1 on the lifting rod 3 absorbs the outer sleeve 4.2 set on the inner cylinder 4.1;

[0046] Step 1.2: Move the translation rod 2 and the lifting rod 3 horizontally to move the safety cone 4 horizontally above the deployment point;

[0047] Step 1.3: The elevating rod 3 moves downward, so that the outer sleeve 4.2 moves downward relative to the inner cylinder 4.1, thereby opening the support foot 4.3 hinged at the bottom of the inner cylinder 4.1 to a horizontal state;

[0048] Step 1.4: The safety cone 4 is detached from the adsorption of the fork suction cup 2.1 and the lifting suction cup 3.1, and placed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com