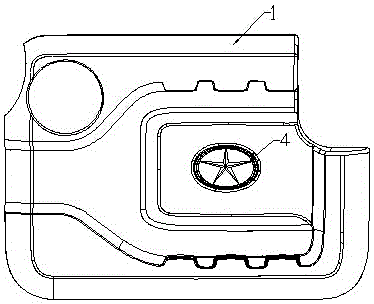

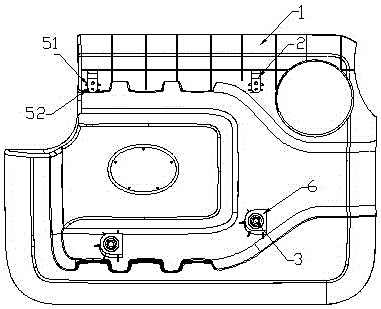

Engine cover assembly

An engine cover and assembly technology, which is applied in the direction of engine components, machines/engines, mechanical equipment, etc., can solve the problems of single appearance of the engine cover, unsightly installation method, complicated installation work, etc., to improve stability and anti-shedding , Easy and fast installation, and the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

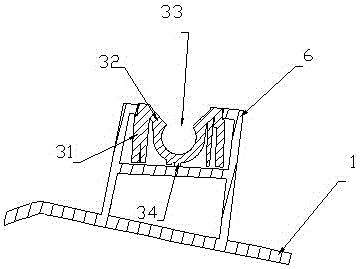

[0018] Depend on figure 1 , figure 2 , image 3 Known, a kind of engine cover assembly, is made up of engine cover main body 1, two pieces of rubber rings 3, and described engine cover main body 1 inner surface is provided with two installation seats 6, and installation seat 6 is provided with circular installation hole, A rubber ring 3 is fixed inside, and the rubber ring 3 consists of an outer ring main body 31, which is arranged on the outer ring end of the rubber ring 3, and has a circular shape that fits with the circular mounting hole on the aforementioned mounting seat 6. A sunken platform is provided on the shape; the inner ring part 32 is integrally formed on the inner side of the outer ring main body part 31. The inner ring part 32 is provided with a center hole 33, and the outer top end of the inner ring part 32 is provided with Boss 34; when the rubber ring 3 is pressed into the circular mounting hole on the mounting seat 6, the rubber ring 3 is limited in the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com