Patents

Literature

42results about How to "Increased resistance to shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

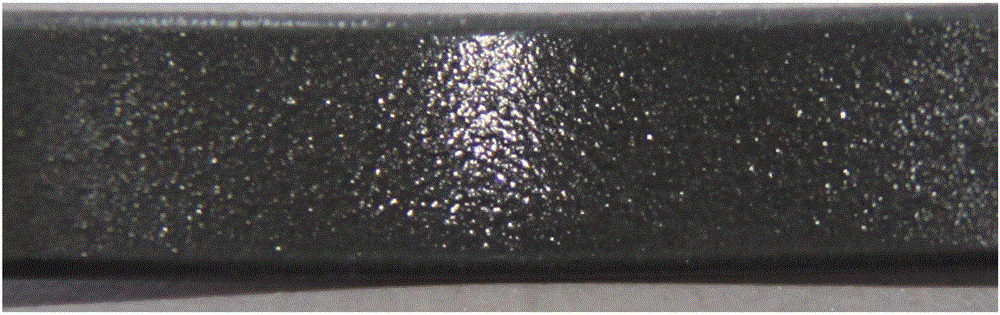

Oxidation-resistant material and method employing same for preparing tantalum-tungsten alloy anti-oxidation coating

ActiveCN105112915AWide operating temperature rangeStrong anti-oxidation ability under continuous static loadMetallic material coating processesAntioxidant capacityThrust chamber

The invention relates to an oxidation-resistant material and a method employing the same for preparing a tantalum-tungsten alloy anti-oxidation coating. The oxidation-resistant material is characterized by comprising a first anti-oxidation material and a second anti-oxidation material, wherein the first anti-oxidation material comprises 1-5wt% of Cr, 1-5wt% of Ti, 0.1-2wt% of Y2O3, 0.5-3wt% of W, 0.5-3wt% of Nb, 1-5wt% of HfO2, and the balance Si; the second anti-oxidation material comprises 6-15wt% of Mo, 0.5-3wt% of W, 0.5-3wt% of Nb, 0.3-2.2wt% of Y, 1-5wt% of HfO2, and the balance Si. The tantalum-tungsten alloy anti-oxidation coating prepared by the method has a wide operating temperature range, and is high in continuous static load and antioxidant capacities, and is particularly suitable for high-temperature structural components such as a thrust chamber, a nozzle jet, a front edge and a guide tube of an airspace engine.

Owner:NINGXIA ORIENT TANTALUM IND +1

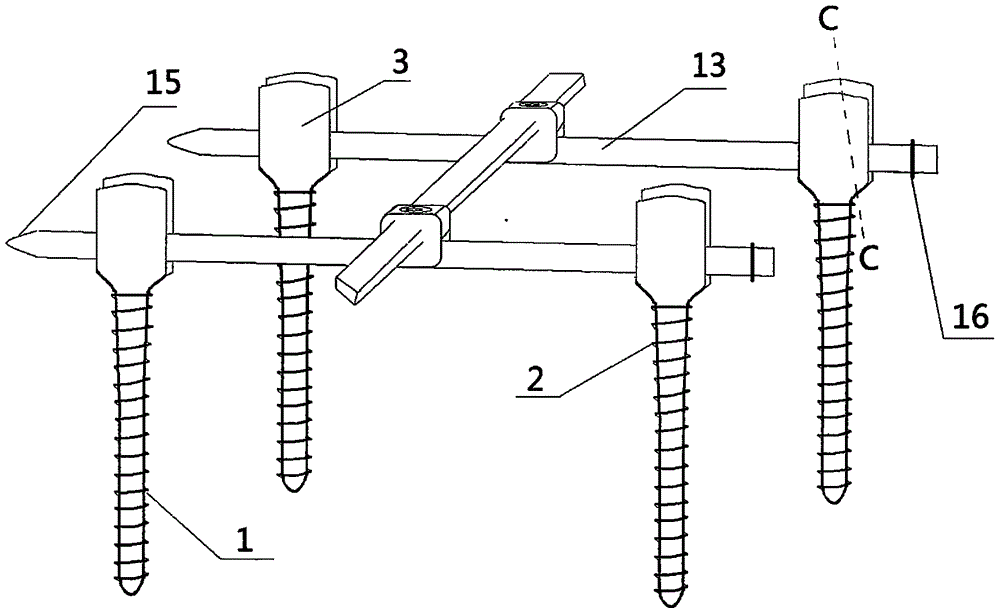

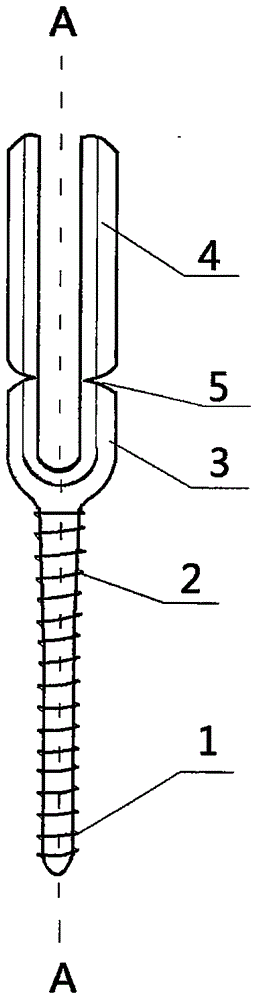

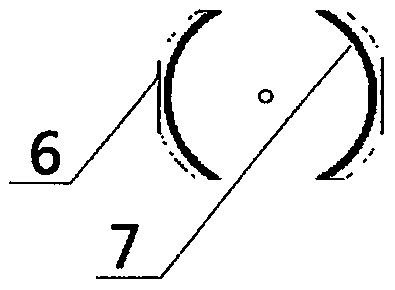

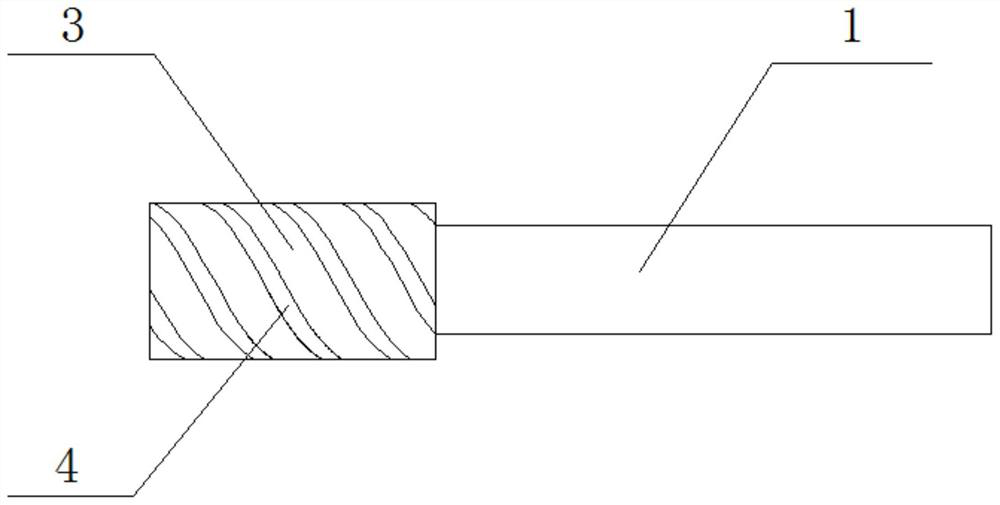

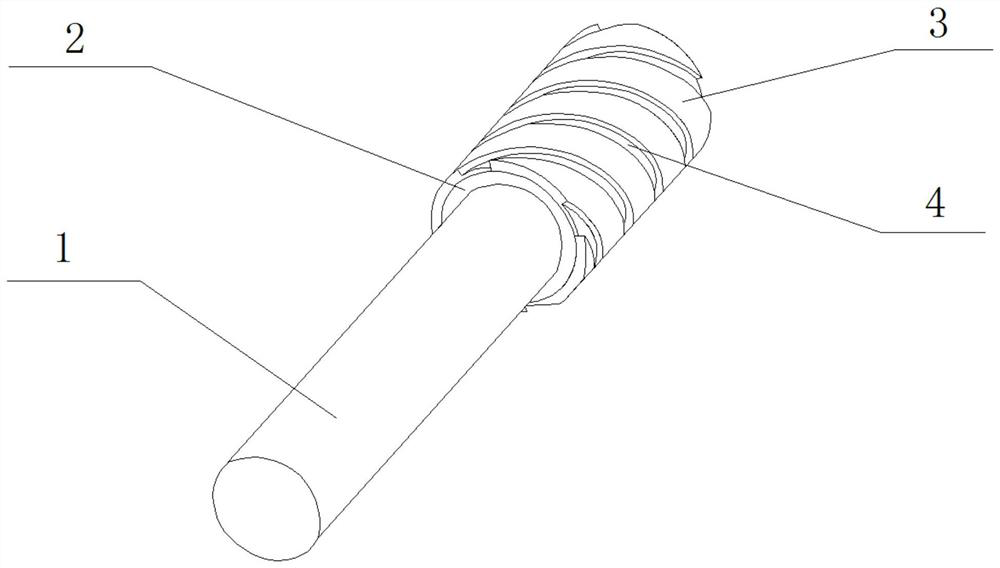

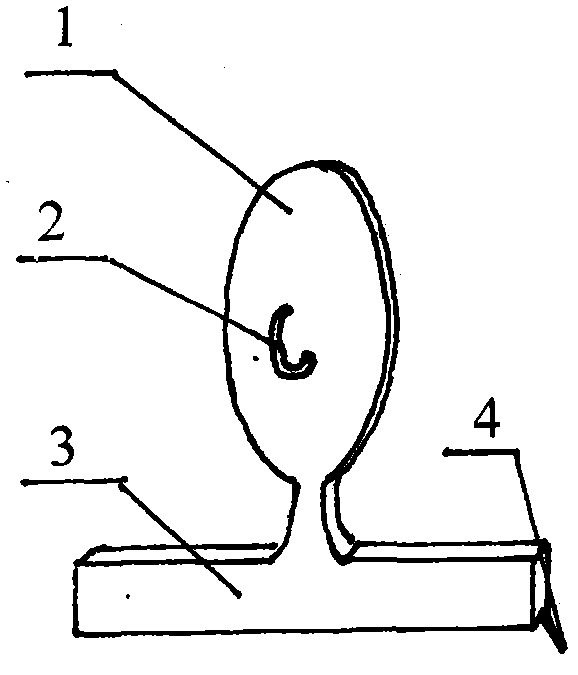

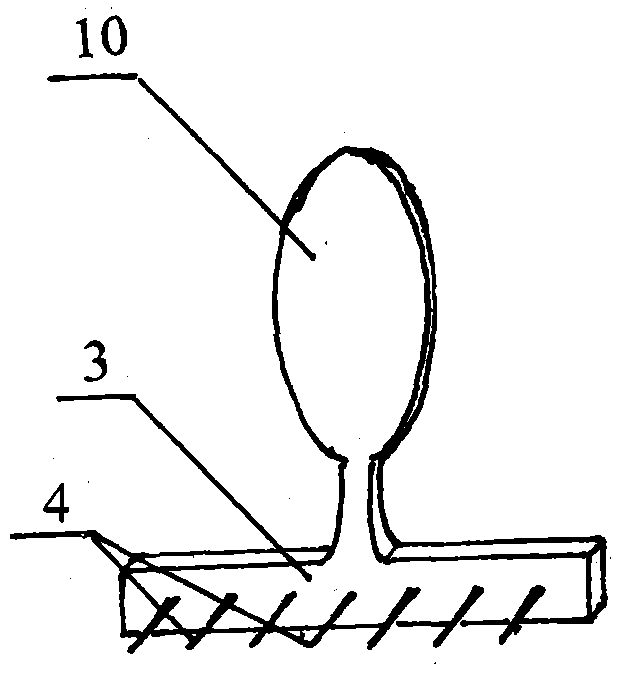

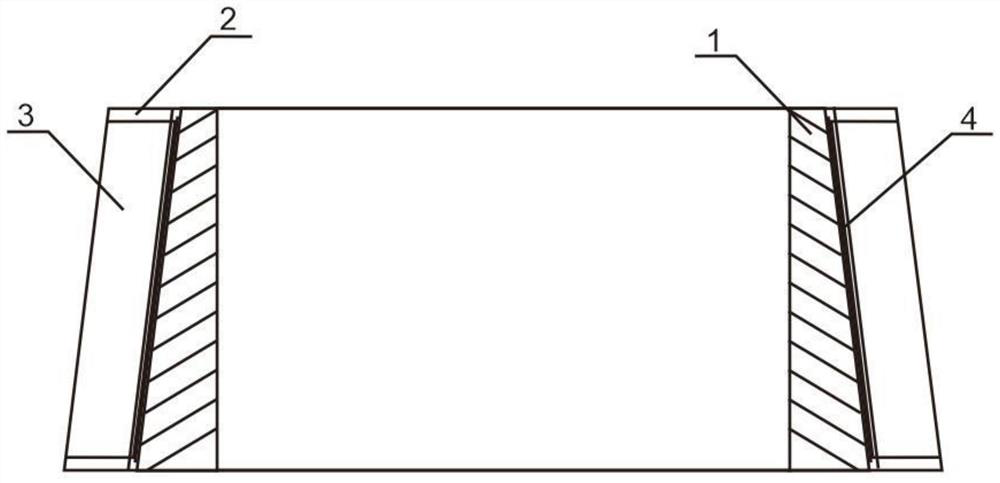

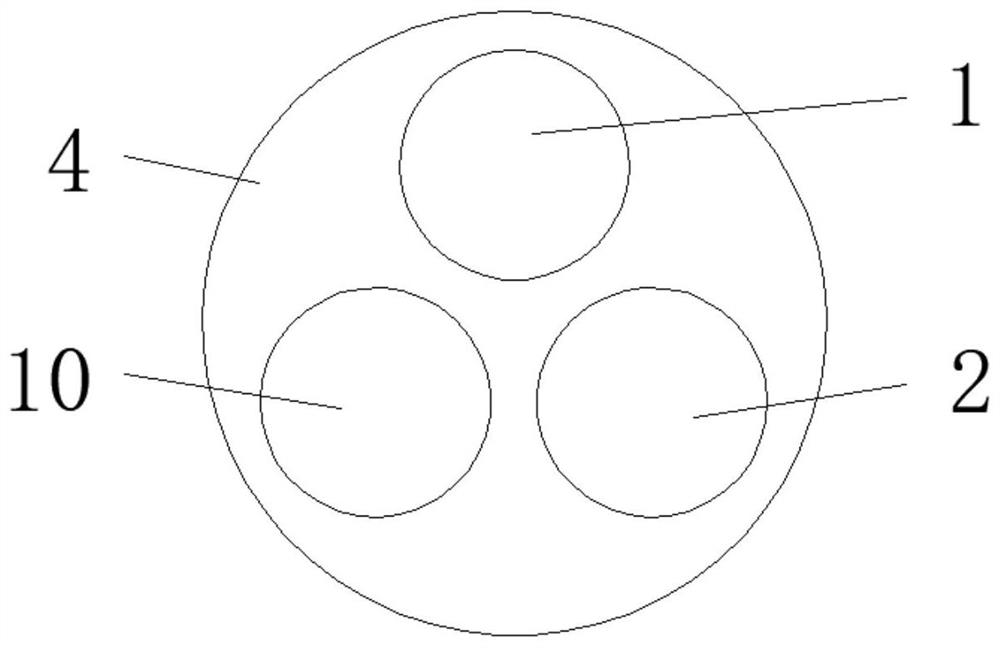

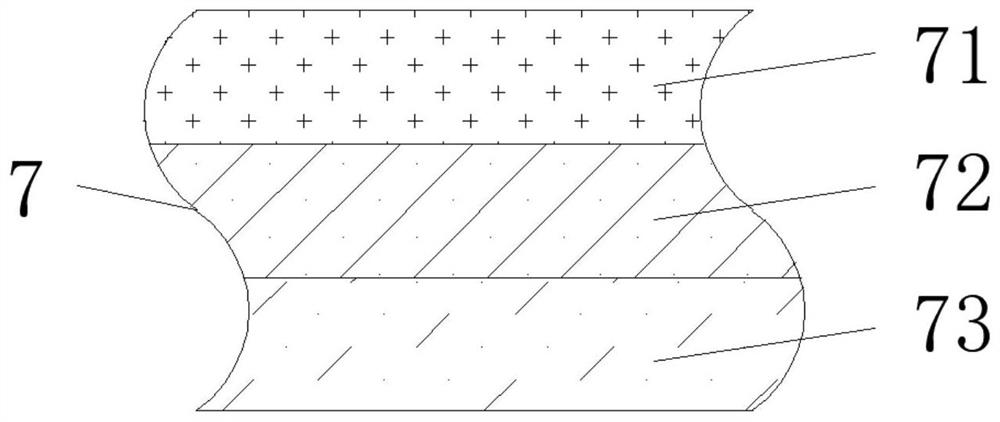

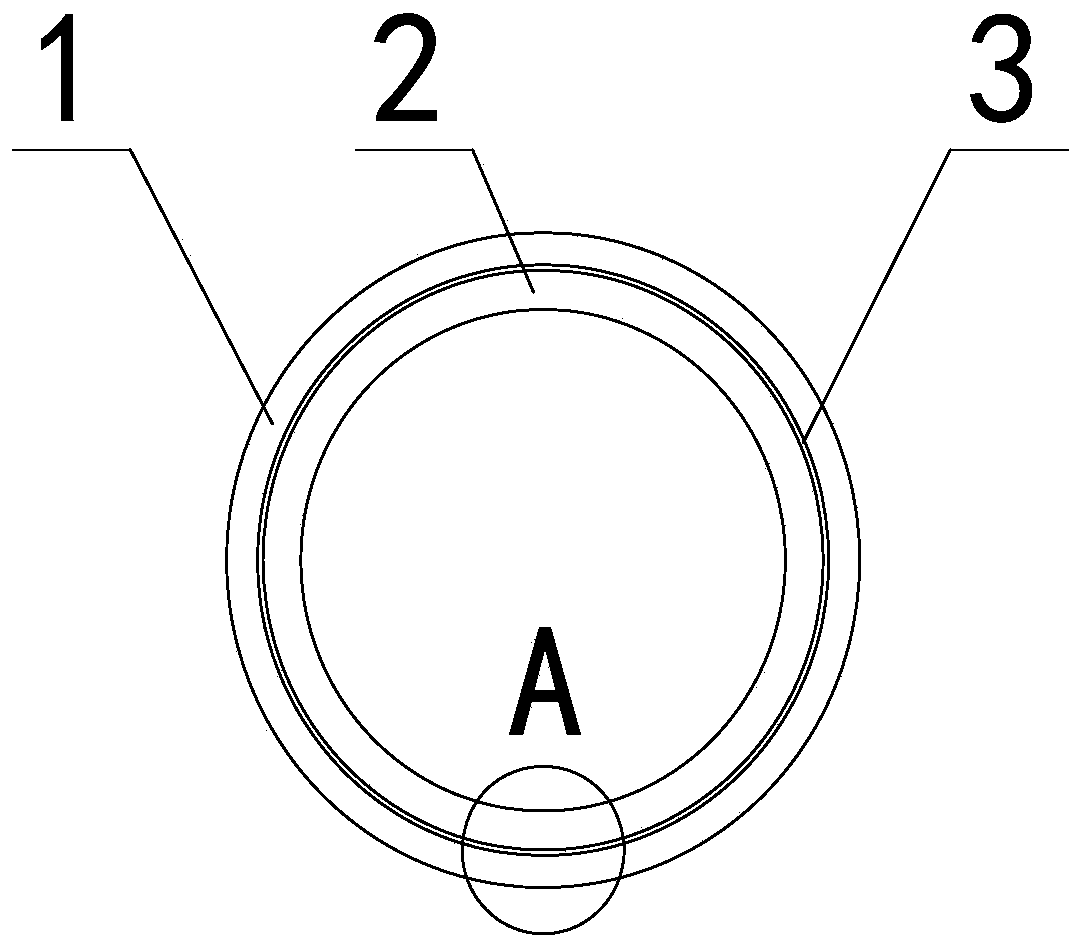

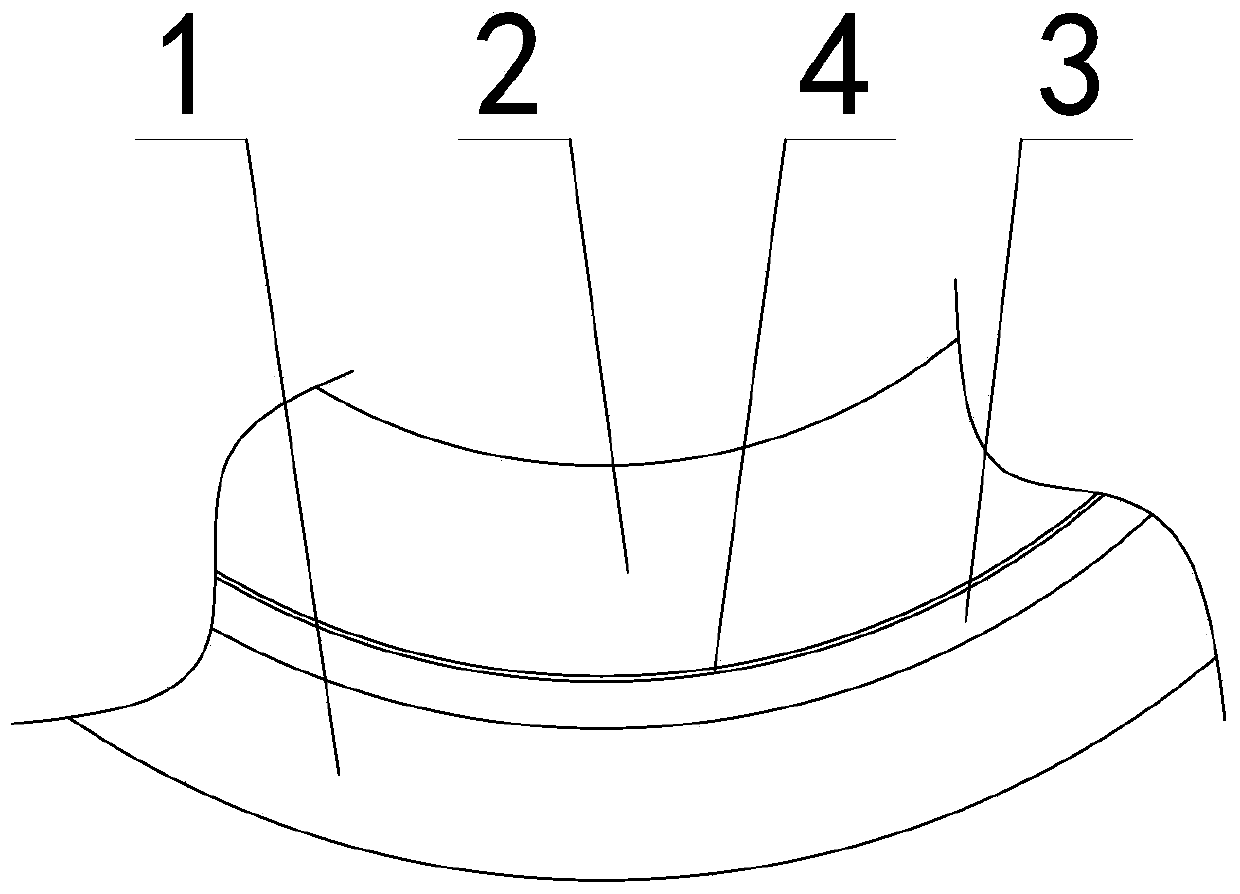

Posterior minimally invasive screw-rod system for thoracolumbar vertebral fracture

InactiveCN105708535AWon't hurtWide range of clinical applicationsInternal osteosythesisMedicineLumbar vertebrae

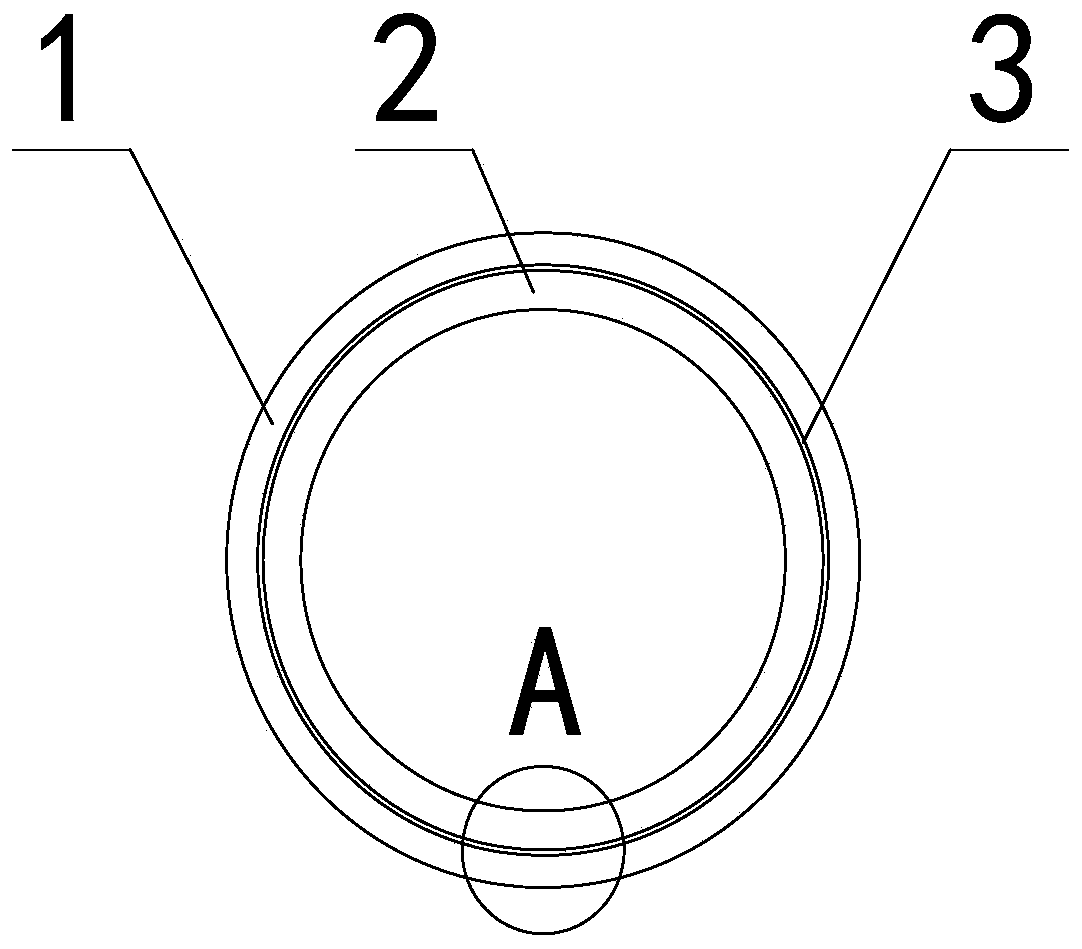

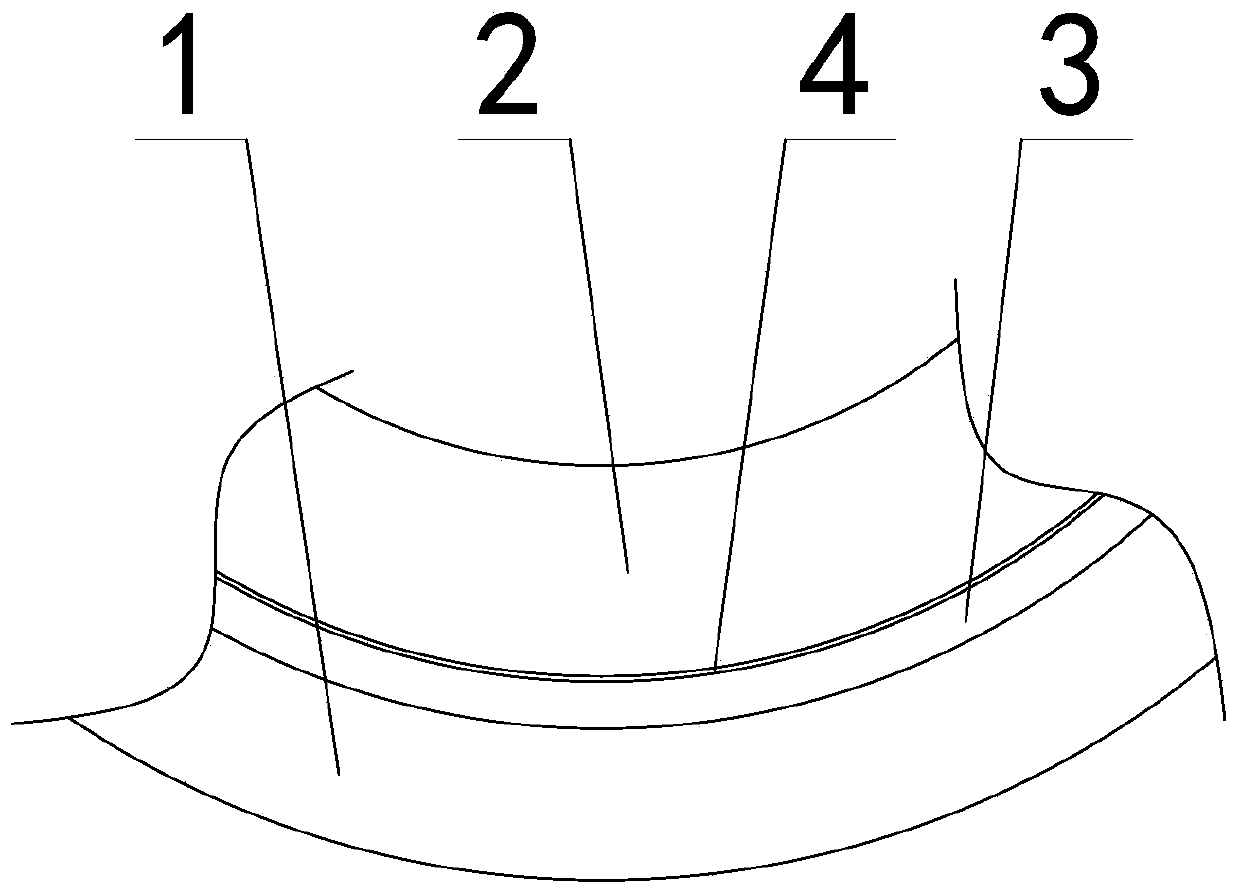

The invention provides a posterior minimally invasive screw-rod system for thoracolumbar vertebral fracture. The posterior minimally invasive screw-rod system is characterized in that each pedicle screw is designed to be a long-tail hollow screw, the far end of the hollow screw is provided with cancellous bone threads (1), the near end of the hollow screw is provided with cortical bone threads (2), a screw tail (3) is U-shaped, and the far end of the screw tail is provided with a long tail (4); a screw tail self-breaking mark (5) is arranged on the outer side of the joint of the screw tail and the long tail, and the outer side of the long tail is provided with a long-tail plane (6); trapezoidal threads (7) are arranged on the inner sides of the screw tail and the long tail, and square-corner grooves (8) are formed in the trapezoidal threads; the outer side of each screw cap is provided with top-horizontal trapezoid-shaped convex threads (9), a plum-blossom-shaped groove (10) is formed in the middle of the screw cap, and is provided with reverse concave threads (11), and the near end of each screw cap is provided with a U-shaped clamp block (12); each screw cap is connected with the corresponding U-shaped clamp block through a movable embedding manner; each connecting rod is a T-shaped rod, the far end of the connecting rod is provided with a main rod (13), and the near end of the connecting rod is provided with a T-shaped handle (14); the tail end of the main rod is provided with a conical tip (15), and the near end of the main rod is provided with a positioning sheet (16); the T-shaped handle is provided with an arc-shaped arm (17); and a connecting rod self-breaking mark (18) is arranged at the joint of the main rod and the arc-shaped arm.

Owner:邓宇

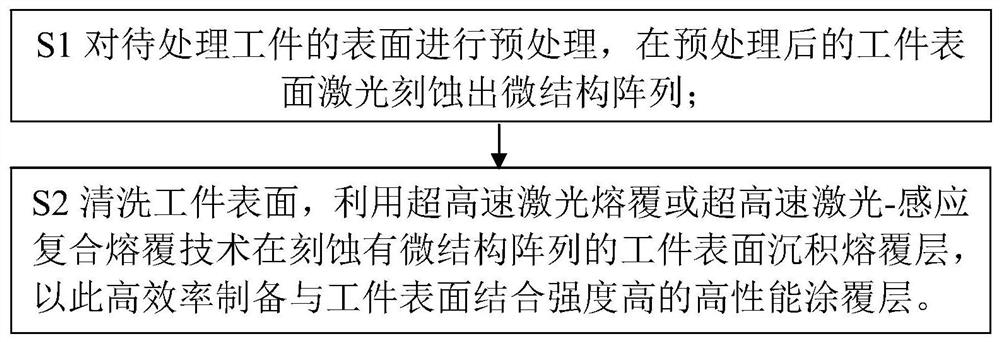

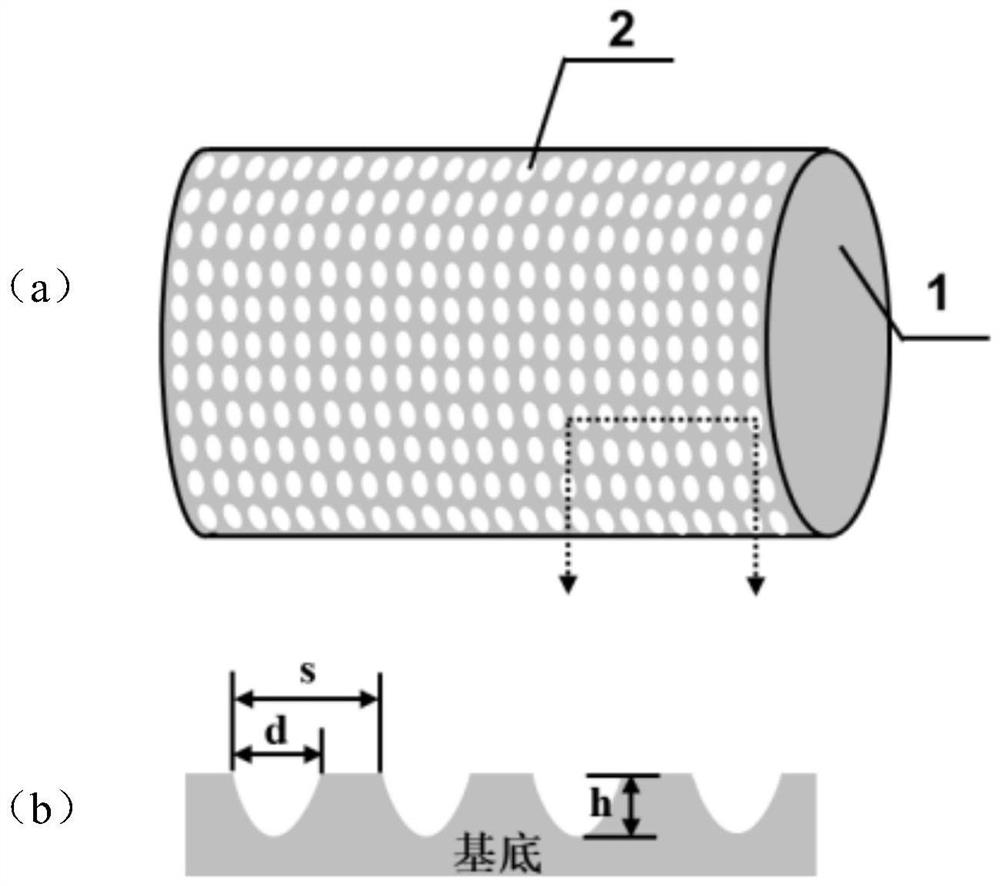

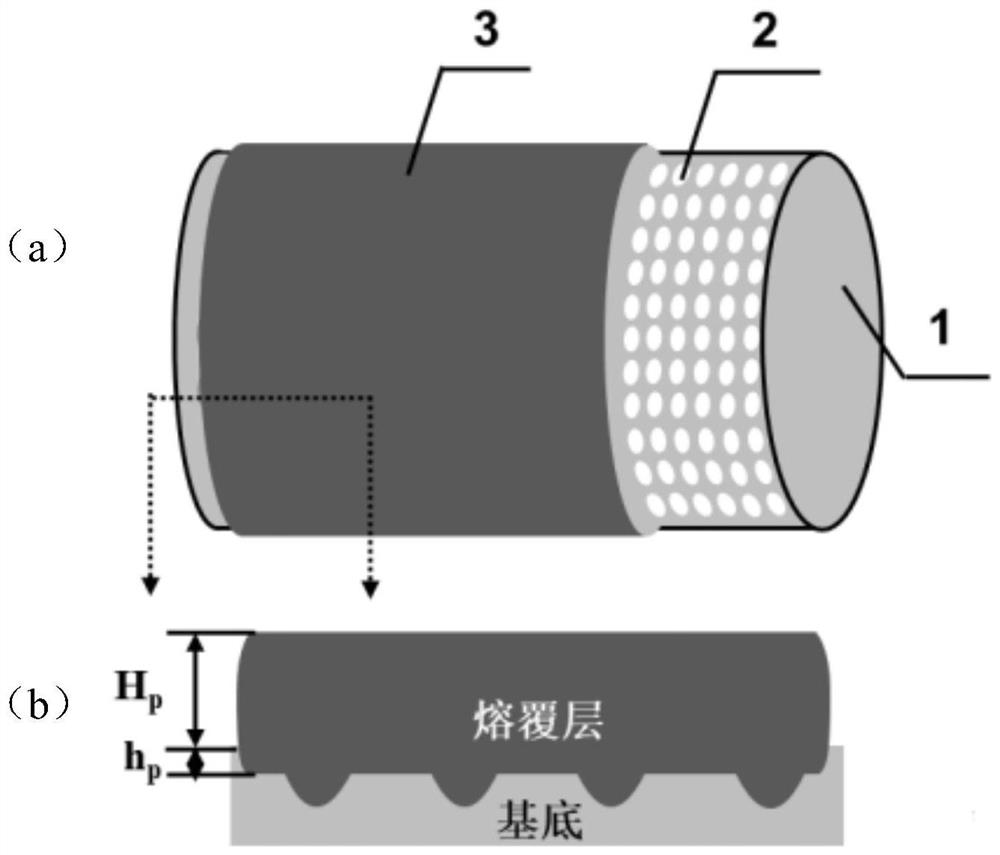

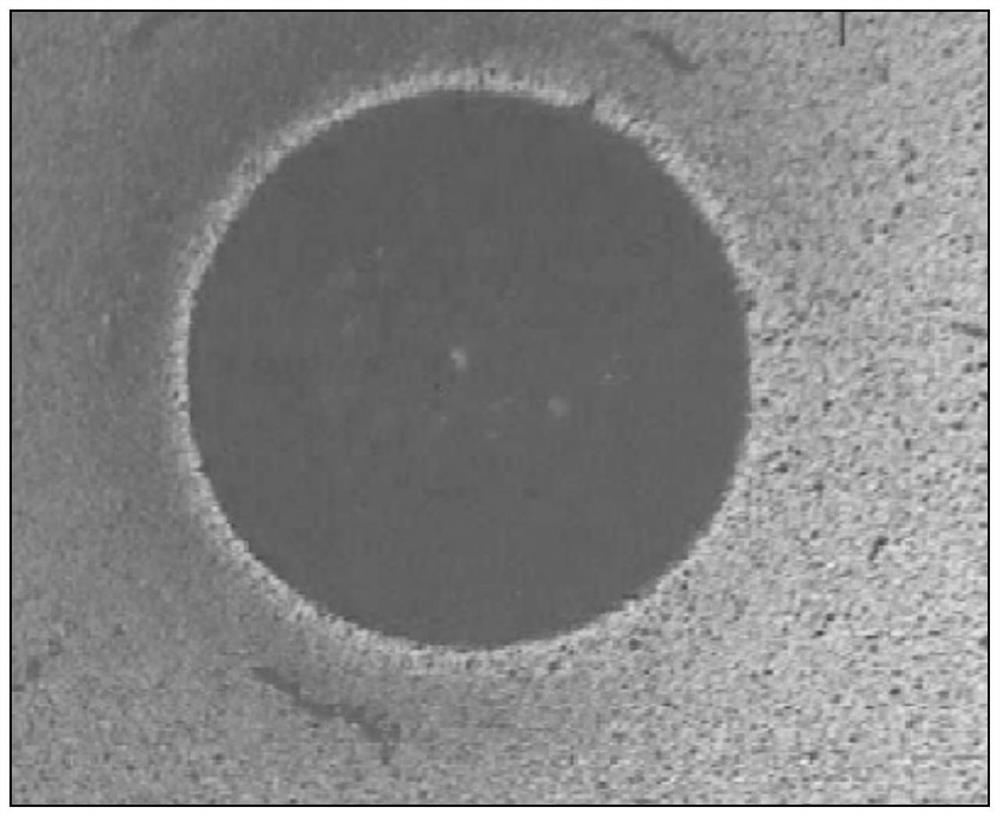

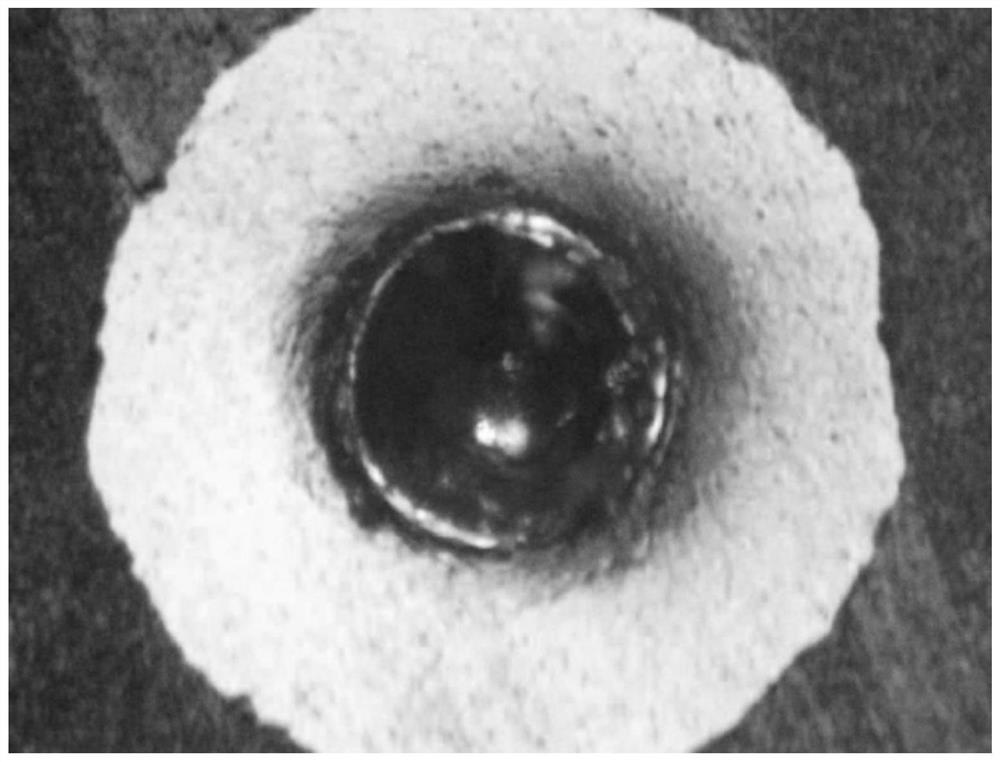

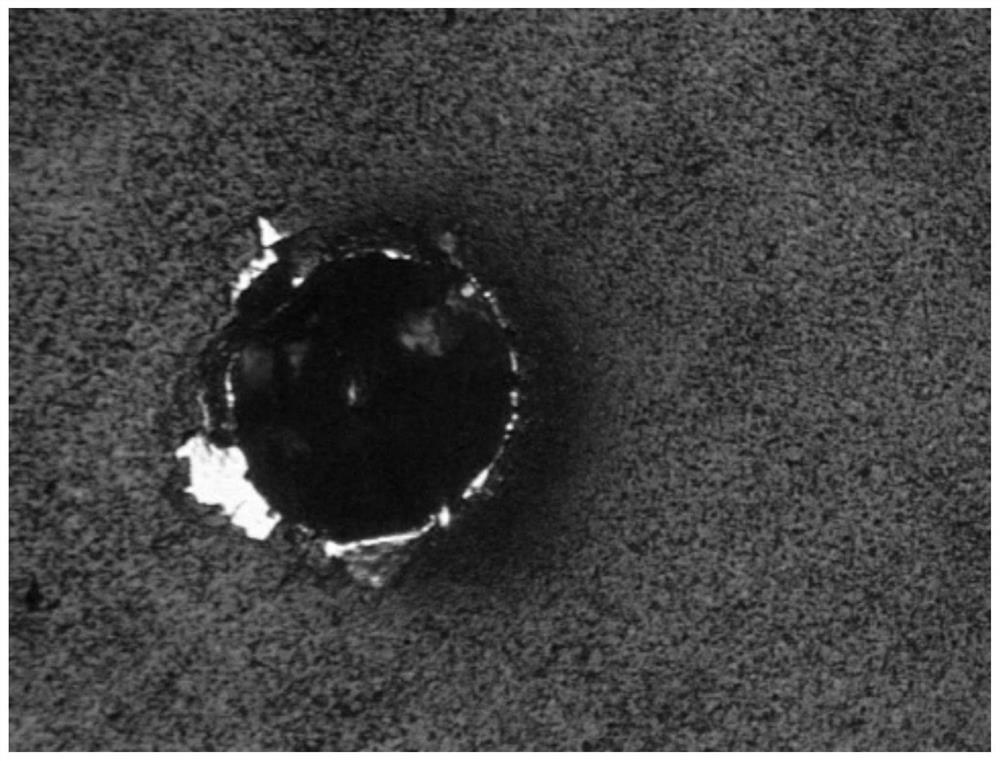

Method and device for efficiently preparing high-performance coating layer

PendingCN112323061AEfficient preparationImprove production efficiencyMetallic material coating processesLaser etchingUltra high speed

The invention belongs to the field of surface coating processing, and particularly discloses a method and a device for efficiently preparing a high-performance coating layer. According to the method,firstly, laser etching is carried out on the surface of a workpiece to be treated to form a microstructure array; and then a cladding layer is deposited on the surface of the workpiece etched with themicrostructure array by utilizing an ultra-high-speed laser cladding technology or an ultra-high-speed laser induction composite cladding technology so as to realize high-efficiency preparation of the high-performance coating layer. According to the method and the device, while the high-performance cladding layer is prepared on the surface of a metal component, the interface bonding area and bonding strength of the cladding layer and a substrate can be improved, the interface stress of the cladding layer and the substrate is reduced, the cladding layer is prevented from being broken and peeled off in the service process, and then the fatigue performance and friction and wear properties of the cladding layer are improved.

Owner:武汉飞能达激光技术有限公司

High-adhesion nano cutter coating and preparation method thereof

PendingCN113652632AImprove structural strengthGood adhesionVacuum evaporation coatingSputtering coatingInterface layerHigh adhesion

The invention relates to the field of hard coatings, and particularly discloses a high-adhesion nano cutter coating and a preparation method thereof. The high-adhesion nano cutter coating comprises a CrN interface layer, an AlTiN intermediate layer, an AlTiN / TiSiN connecting layer and a TiSiN coating layer which are sequentially coated on the cutter surface subjected to matrix modification from inside to outside, and the CrN interface layer, the AlTiN intermediate layer, the AlTiN / TiSiN connecting layer and the TiSiN coating layer are prepared by adopting a deposition coating scheme. The preparation method comprises the following steps: S1, taking a matrix modified cutter, and activating; and S2, after activation of the cutter is completed, performing deposition in sequence, and preparing the high-adhesion nanom cutter coating. In addition, the surface structure of the cutter material is optimized, and the adhesion performance and anti-falling performance of the hard coating on the cutter surface are improved.

Owner:科汇纳米技术(常州)有限公司

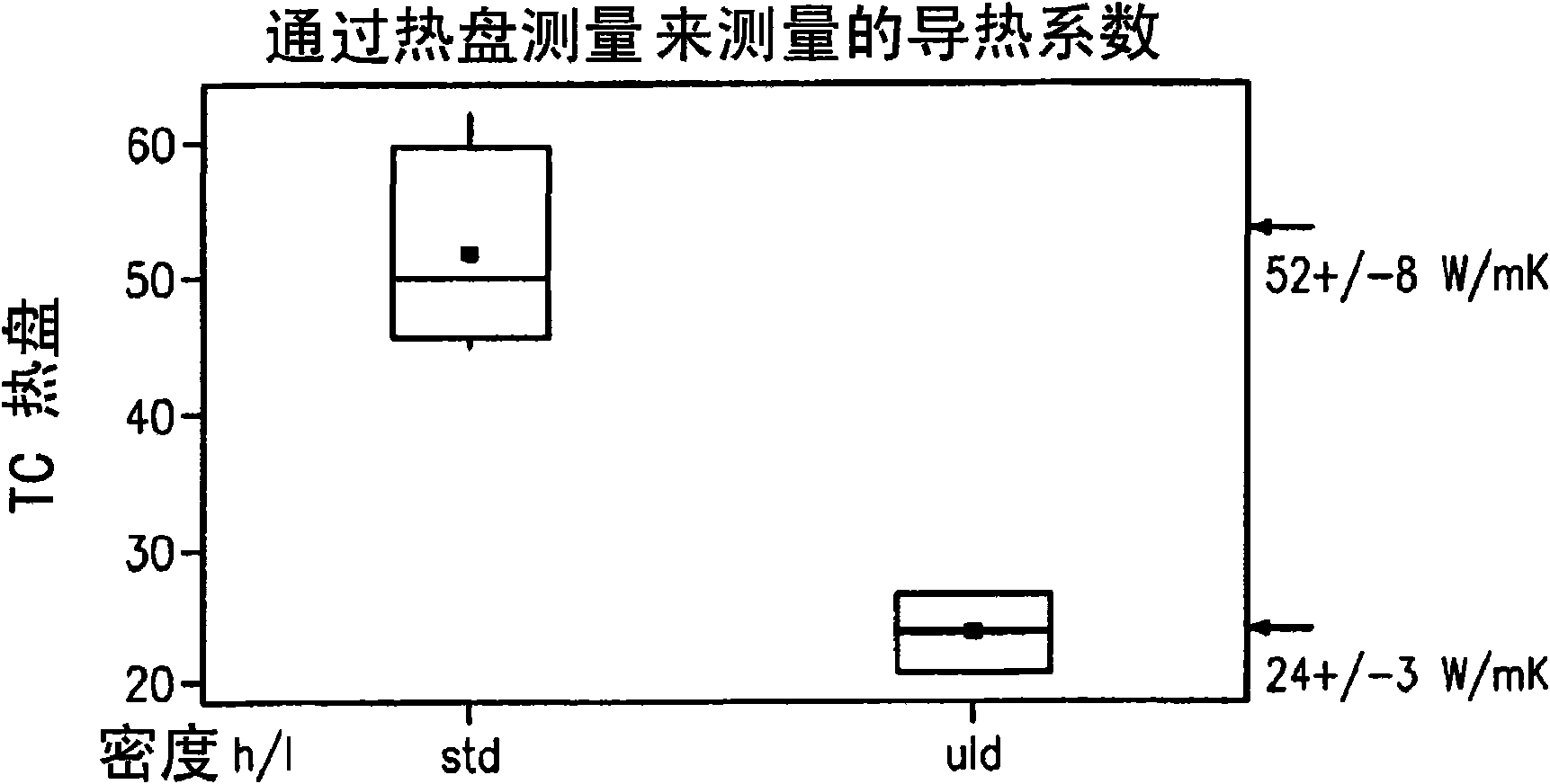

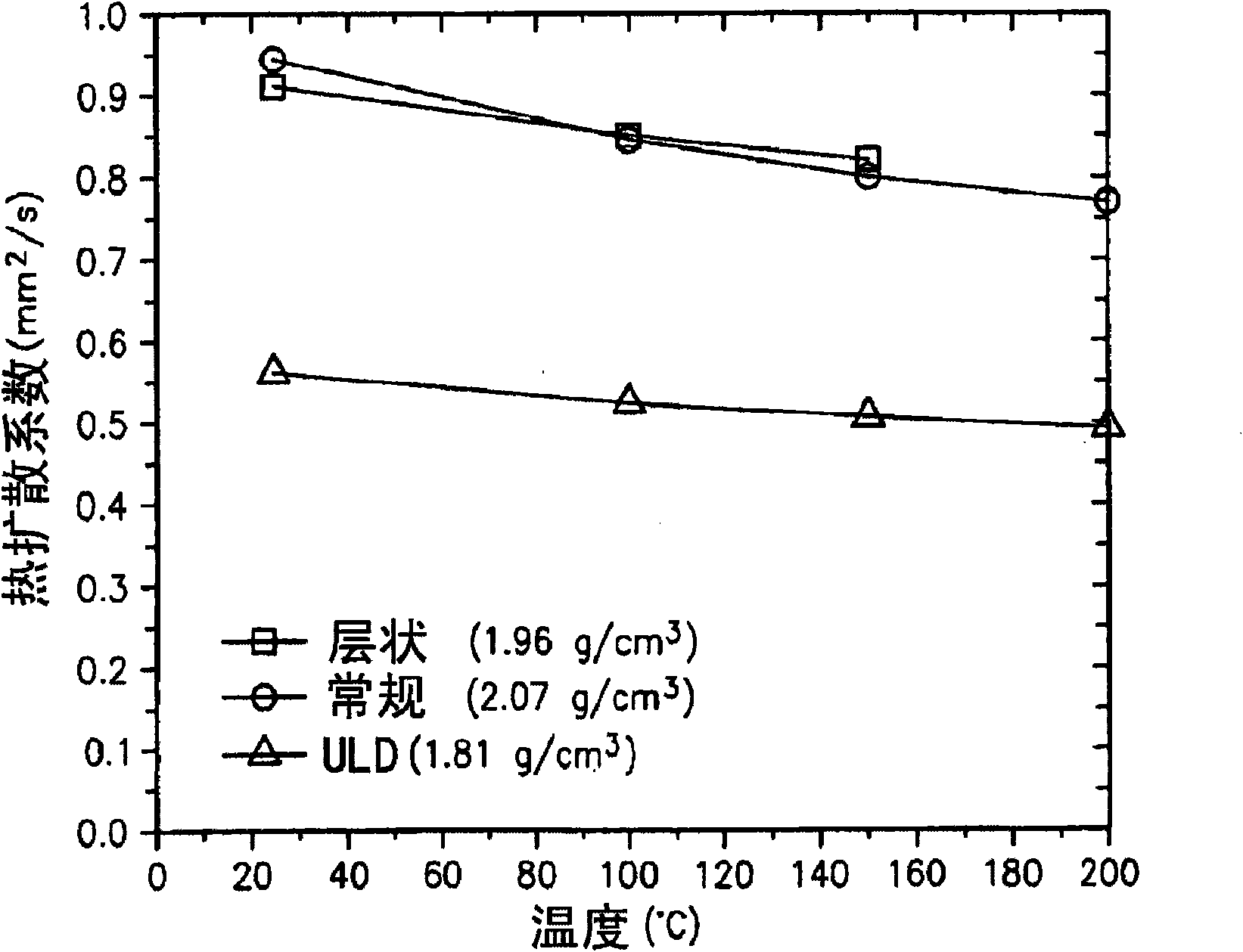

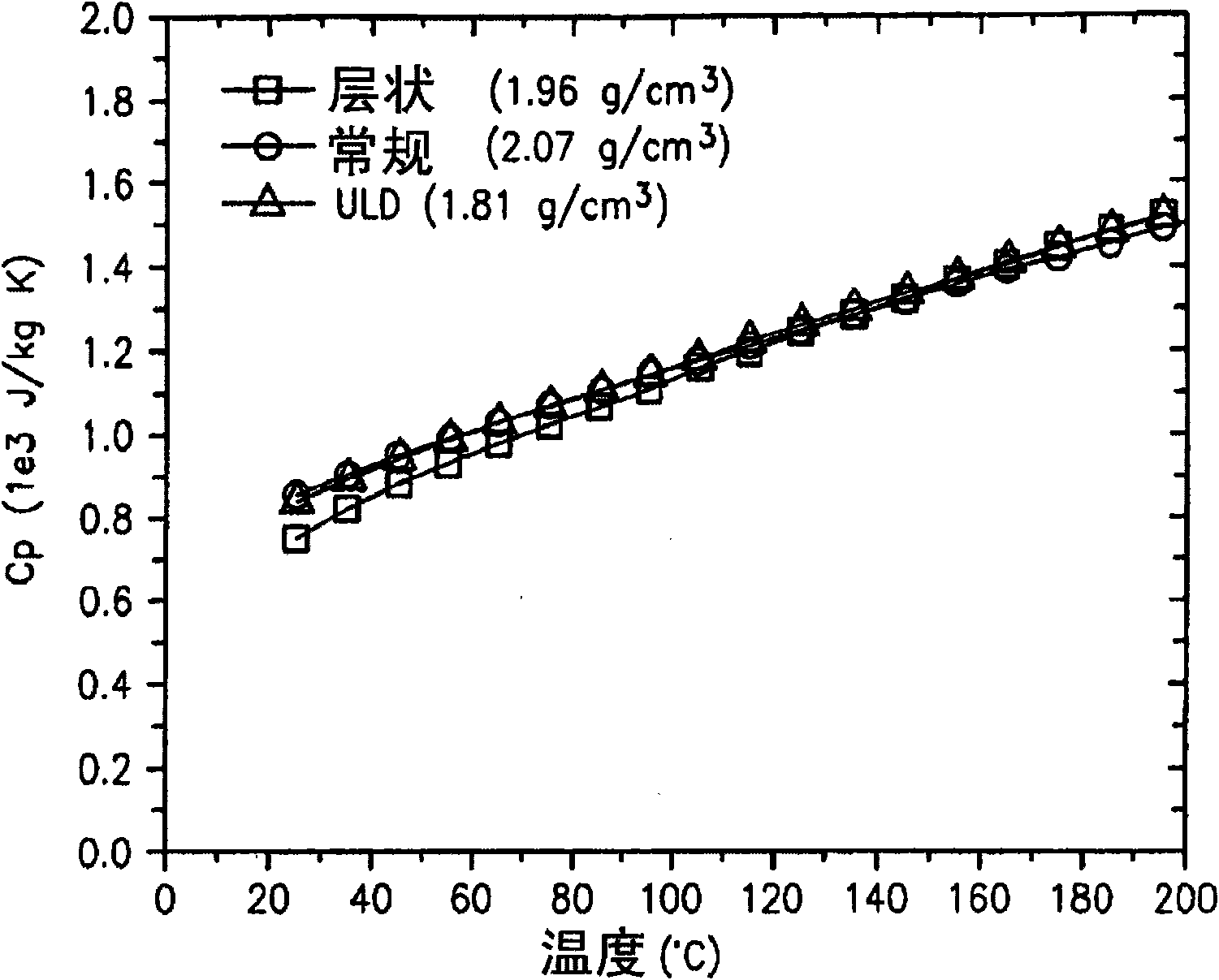

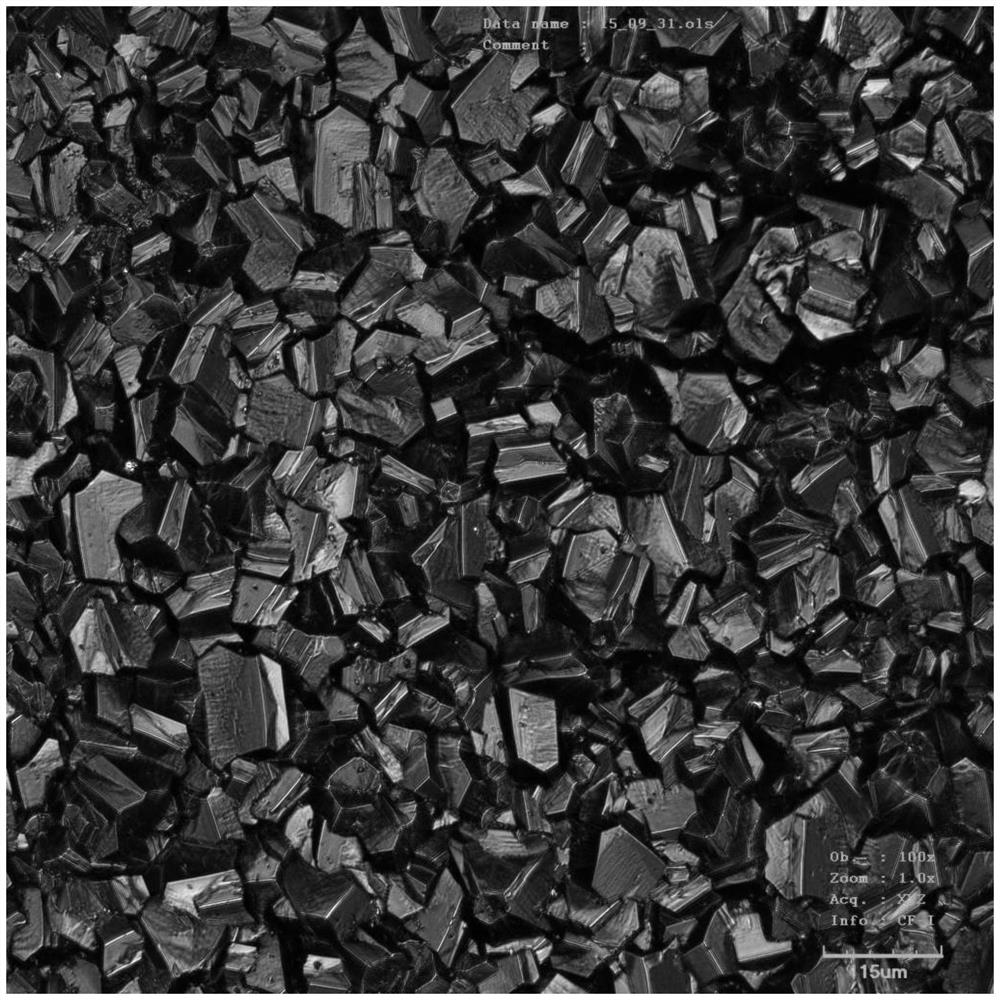

Low thermal conductivity low density pyrolytic boron nitride material, method of making, and articles made therefrom

InactiveCN101952226AIncreased resistance to sheddingHigh heat controlAfter-treatment apparatusPolycrystalline material growthIn planeMetallurgy

A pyrolytic boron nitride material is disclosed having an in-plane thermal conductivity of no more than about 30 W / m-K and a through-plane thermal conductivity of no more than about 2 W / m-K. The density is less than 1.85 g / cc.

Owner:MOMENTIVE PERFORMANCE MATERIALS INC

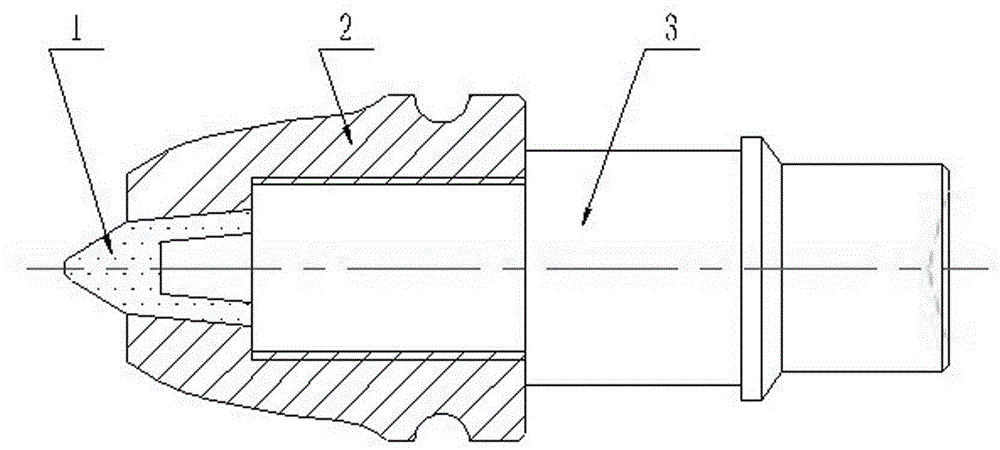

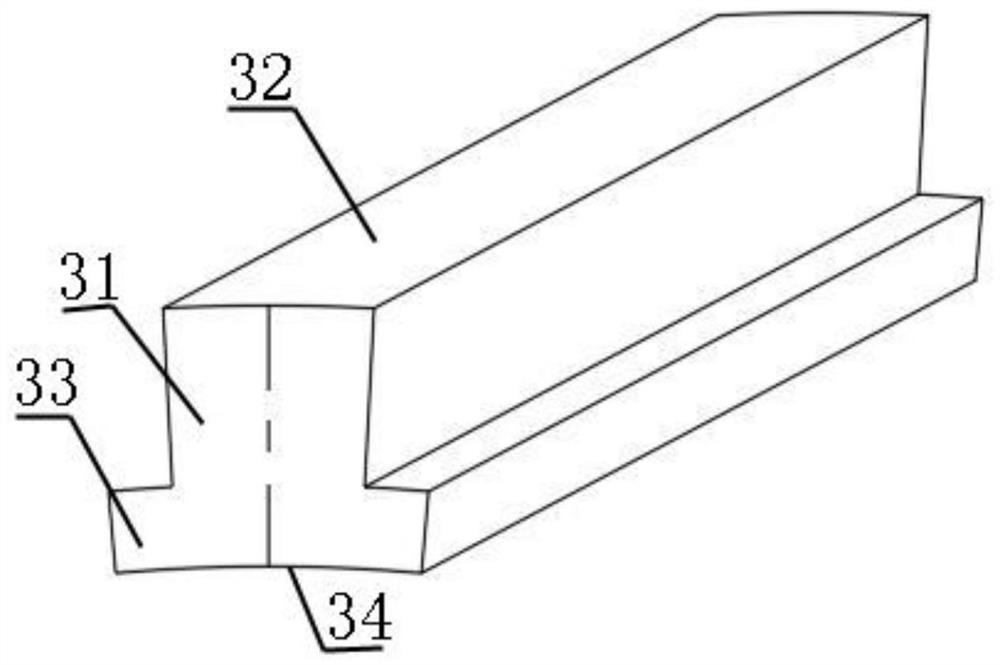

Anti-falling cutting pick with composite assembled structure

InactiveCN102996126APerformance is not affectedExtend your lifeSlitting machinesStructural engineeringMechanical engineering

The invention discloses a high-performance anti-falling cutting pick with a composite assembled structure. The cutting pick comprises a cutting pick shank, a cutting pick head, and a protective fixing sleeve. One end of the cutting pick shank is a fixing end. The other end of the cutting pick shank and the cutting pick head form a taper connection through self-locking. The cutting pick head has an inner taper hole, and the cutting pick shank has an outer taper shank. The protective fixing sleeve and the cutting pick head also form a taper connection through self-locking. The cutting pick head has an outer taper shank, and the protective fixing sleeve has an inner taper hole. The protective fixing sleeve and the cutting pick shank are threadedly connected. With the cutting pick provided by the invention, cutting pick head anti-falling capacity and cutting pick service life can be improved, construction efficiency can be effectively improved, and construction cost can be reduced.

Owner:SHENYANG LIGONG UNIV

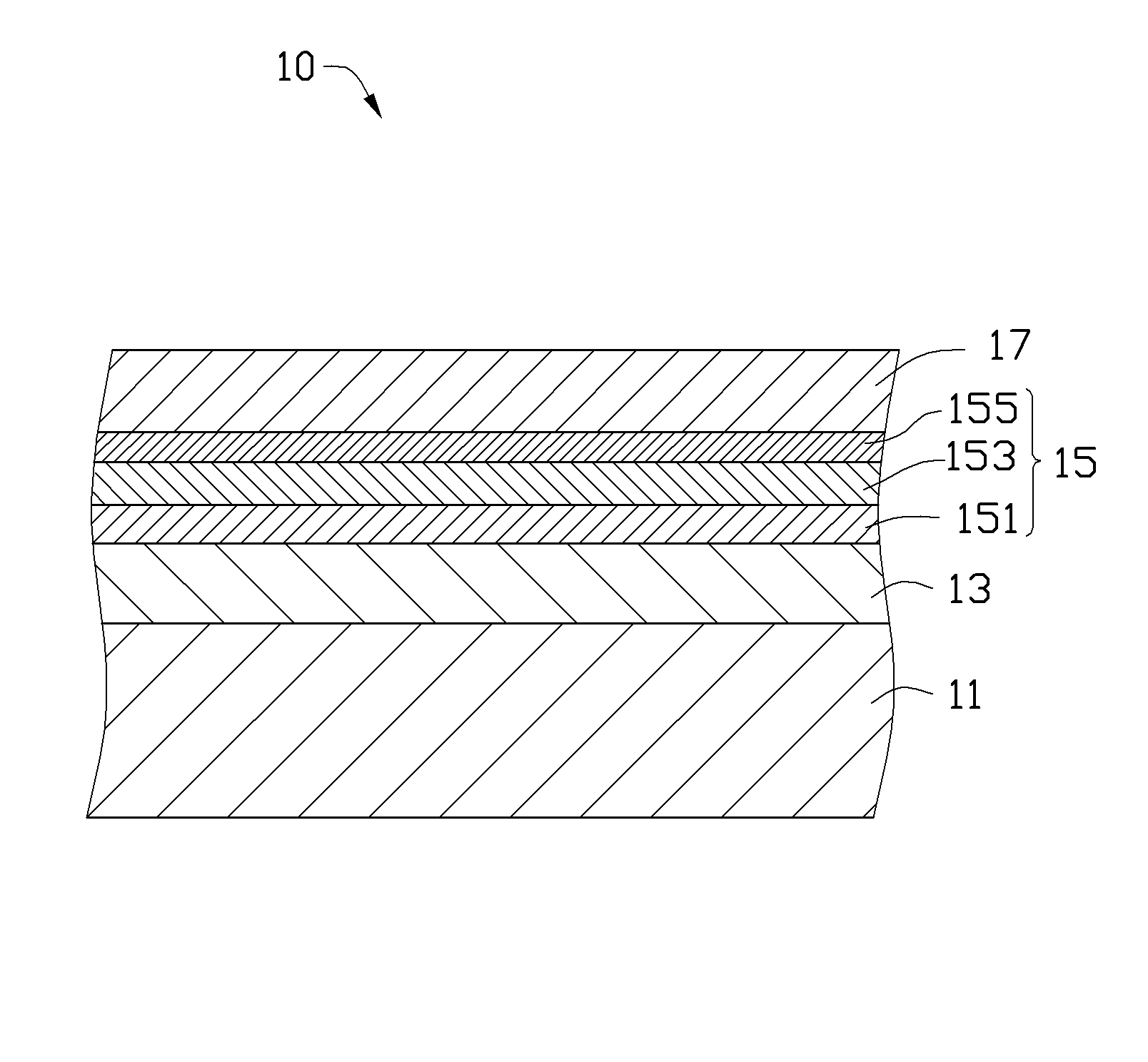

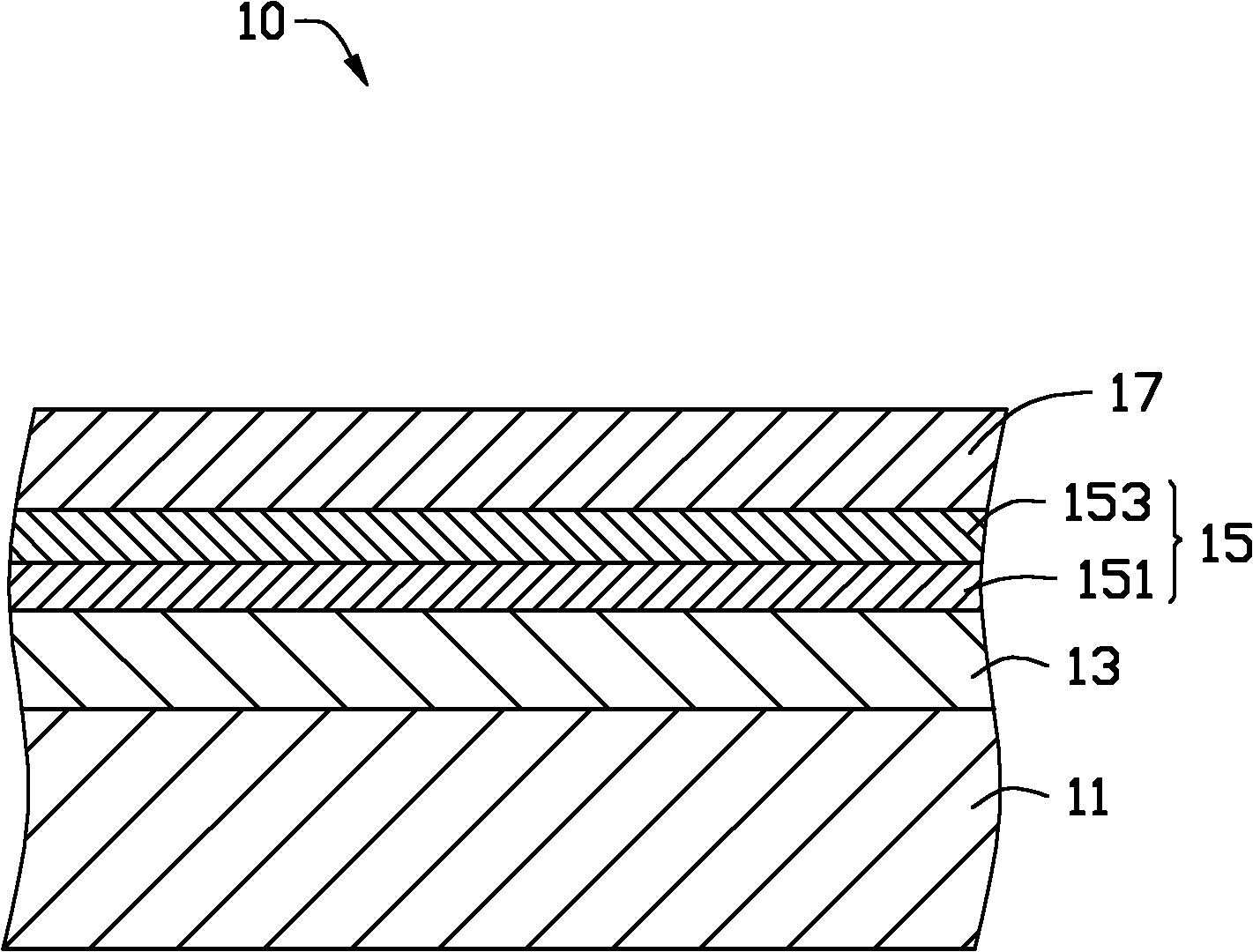

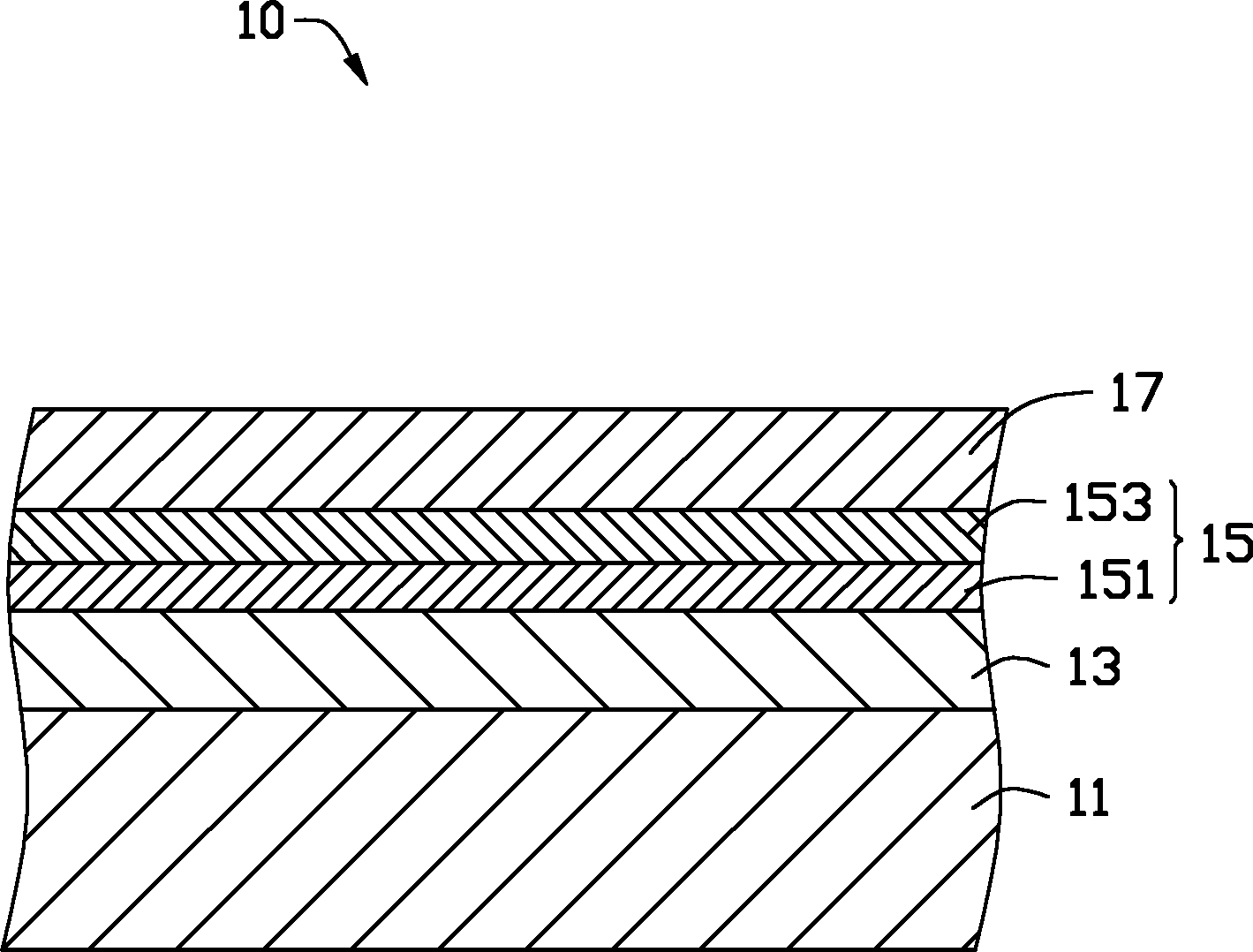

Covering member and manufacture method thereof

InactiveCN102732846AStrong adhesionImprove antioxidant capacityVacuum evaporation coatingSputtering coatingSputteringHafnium

The invention provides a covering member, comprising a hard matrix on which a transition layer, a composite hard layer and an antioxidation layer are formed in sequence. The transition layer is a chromium layer. The composite hard layer consists of a chromium nitride layer, a hafnium nitride layer and a molybdenum nitride layer. The antioxidation layer is an aluminum oxide layer. In addition, the invention also provides a manufacture method for the covering member. The method comprises the following steps of: providing the hard matrix; and forming the transition layer, the composite hard layer and the antioxidation layer in sequence on the hard matrix through magnetron sputtering. The covering member manufactured by the method has high hardness as well as a relatively good antioxidation performance.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Coating and production method thereof

InactiveCN102634760AGood adhesionImprove antioxidant capacityVacuum evaporation coatingSputtering coatingHardnessChromium nitride

The invention provides a coating, which comprises a hard base, a transition layer, a composite hard layer and an antioxidant layer, wherein the transition layer, the composite hard layer and the antioxidant layer are formed sequentially on the hard base. The transition layer is a chromium layer. The composite hard layer is composed of a chromium nitride layer and a hafnium nitride layer. The antioxidant layer is an aluminum oxide layer. In addition, the invention provides a production method of the coating, which includes the steps of providing the hard base, and sequentially forming the transition layer, the composite hard layer and the antioxidant layer on the hard base by magnetron sputtering. The coating produced by the method is high in hardness and fine in oxidation resistance.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

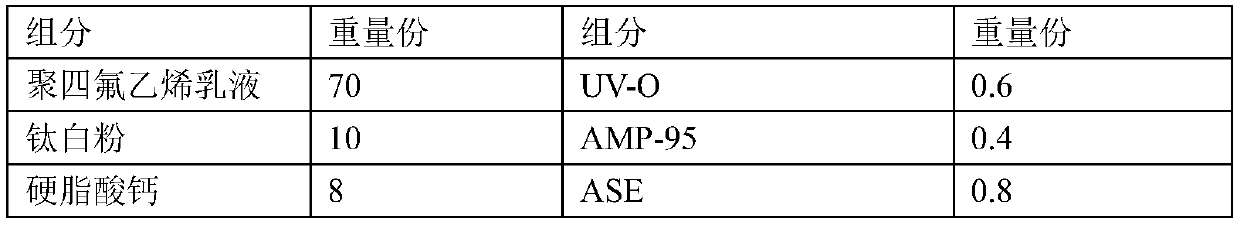

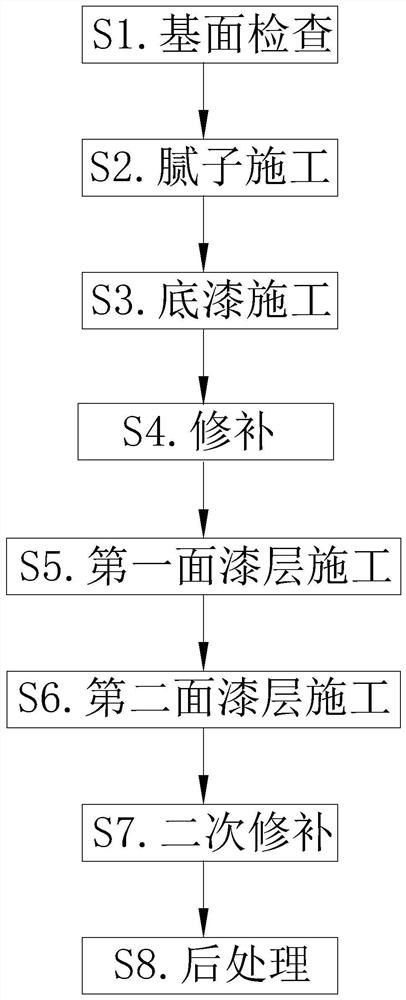

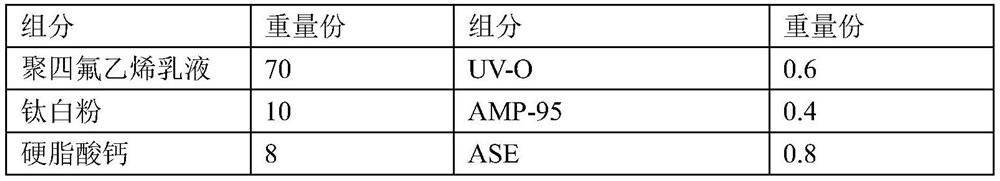

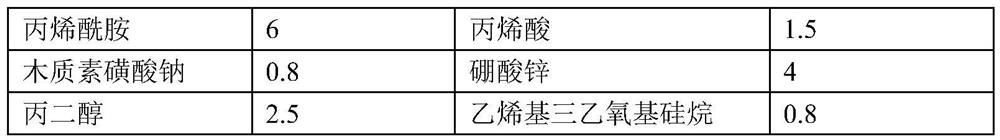

Building exterior wall coating with good weather resistance and exterior wall coating construction process

ActiveCN110804357AIncrease surface tensionIncrease contact areaCovering/liningsCoatingsWeather resistanceEmulsion

The invention relates to a building exterior wall coating with good weather resistance and an exterior wall coating construction process. The building exterior wall coating comprises a coating for a first finish paint layer and a coating for a second finish paint layer, the coating for the first finish paint layer comprises the following components in parts by weight: 45-65 parts of a polyacrylateemulsion, 10-15 parts of calcium bicarbonate, 5-8 parts of polyacrylamide resin particles, 2-4 parts of polyvinyl alcohol, 1-2 parts of propylene glycol, 1-3 parts of magnesium hydroxide, 0.4-0.8 part of sodium lignin sulfonate, 0.5-1.5 parts of a thickening agent and 5-10 parts of quartz sand. The coating for the second finish paint layer comprises the following components in parts by weight: 40- 70 parts of Polytetrafluoroethylene emulsion, 6-10 parts of titanium dioxide, 5 to 8 parts of calcium stearate, 3 to 6 parts of acrylamide, 0.4 to 0.8 part of sodium lignin sulfonate, 1.5 to 2.5 parts of propylene glycol, 0.3 to 0.6 part of UV-O, 0.5 to 1.5 parts of acrylic acid, 2 to 4 parts of zinc borate, 0.4 to 0.8 part of vinyltriethoxysilane and 0.7 to 1.2 parts of a thickening agent. Theweather resistance of the coating within the service life is improved.

Owner:深圳陆城装饰设计工程有限公司

Small deep hole inner wall ultrasonic vibration machining cutter and a preparation method thereof

ActiveCN113732366AHigh strengthStable structureNuclear energy generationTransportation and packagingCooling effectEngineering

The invention discloses a small deep hole inner wall ultrasonic vibration machining cutter and a preparation method thereof, and belongs to the technical field of small deep hole inner wall machining. The tool and the method solve the technical problem that in the small deep hole inner wall high-frequency ultrasonic vibration machining process, a cutter is prone to abrasion due to the fact that heat is generated by friction and the cooling effect is poor. A cutter handle and a cutter base are integrated cylindrical connectors with different diameters, the cutter base is coated with a CVD diamond coating, a spiral groove is formed in the CVD diamond coating, and the cutter handle and the cutter base are both made of SiC. The CVD diamond coating on the surface of the cutter has higher abrasive particle density and does not contain any binding agent, so that the cutter has higher hardness and better wear resistance; and the spiral groove increases a chip containing space and can effectively improve the grinding performance and the chip removal and heat removal capacity, the machining stability of the cutter is improved, the service life of the cutter is prolonged, and high-efficiency, high-precision and high-quality ultrasonic vibration machining of the inner wall of a micro hole is achieved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Preparation method of alkali-activated copper slag-based pervious concrete and alkali-activated copper slag-based pervious concrete

The invention provides a preparation method of alkali-activated copper slag-based pervious concrete and the alkali-activated copper slag-based pervious concrete. The method comprises the following steps: (1) respectively carrying out dry grinding on copper slag and carbide slag to obtain copper slag powder and carbide slag powder; crushing the red mud, and performing dry grinding to obtain red mud powder; (2) 195-205 parts by weight of copper slag powder and 95-105 parts by weight of water are taken, 0.1-0.2 part by weight of a water reducing agent is added, wet grinding is conducted for 15-25 min, and copper slag slurry is obtained and marked as slurry A; taking 80-83 parts by weight of red mud powder and 160-165 parts by weight of water, and performing wet grinding for 20-40 minutes to obtain red mud slurry which is marked as slurry B; (3) mixing ammonium tartrate, sodium sulfate, lignosulfonate, hydroxypropyl methyl cellulose and wood fiber according to a ratio of 1: 2: 3: 1: 1 to prepare a reinforcing agent; and (4) uniformly stirring 20-40 parts by weight of carbide slag powder, 50-60 parts by weight of the slurry A, 30-40 parts by weight of the slurry B, 2-8 parts by weight of sodium carbonate, 5-15 parts by weight of water, 2-3 parts by weight of a reinforcing agent, 1-2 parts by weight of a water reducing agent, 120-160 parts by weight of river sand, 40-80 parts by weight of copper slag powder and 250-350 parts by weight of coal gangue.

Owner:HUBEI UNIV OF TECH

A kind of building exterior wall coating with good weather resistance and construction technology of exterior wall coating

ActiveCN110804357BIncrease surface tensionHigh strengthCovering/liningsCoatingsPolymer scienceCalcium bicarbonate

The invention relates to a building exterior wall coating with good weather resistance and a construction process of the exterior wall coating. The building exterior wall coating includes a coating for the first top paint layer and a coating for the second top paint layer. The coating for the first top paint layer is divided into Parts by weight include the following components: 45-65 parts of polyethylacrylate emulsion, 10-15 parts of calcium bicarbonate, 5-8 parts of polyacrylamide resin particles, 2-4 parts of polyvinyl alcohol, 1-2 parts of propylene glycol, hydrogen 1-3 parts of magnesium oxide, 0.4-0.8 parts of sodium lignosulfonate, 0.5-1.5 parts of thickener and 5-10 parts of quartz sand; the coating for the second topcoat layer comprises the following components by weight: polytetrafluoroethylene Ethylene emulsion 40‑70 parts, titanium dioxide 6‑10 parts, calcium stearate 5‑8 parts, acrylamide 3‑6 parts, sodium lignosulfonate 0.4‑0.8 parts, propylene glycol 1.5‑2.5 parts, UV‑O0. 3-0.6 parts, 0.5-1.5 parts of acrylic acid, 2-4 parts of zinc borate, 0.4-0.8 parts of vinyltriethoxysilane and 0.7-1.2 parts of thickener. The invention improves the weather resistance performance of the coating within the service life.

Owner:深圳陆城装饰设计工程有限公司

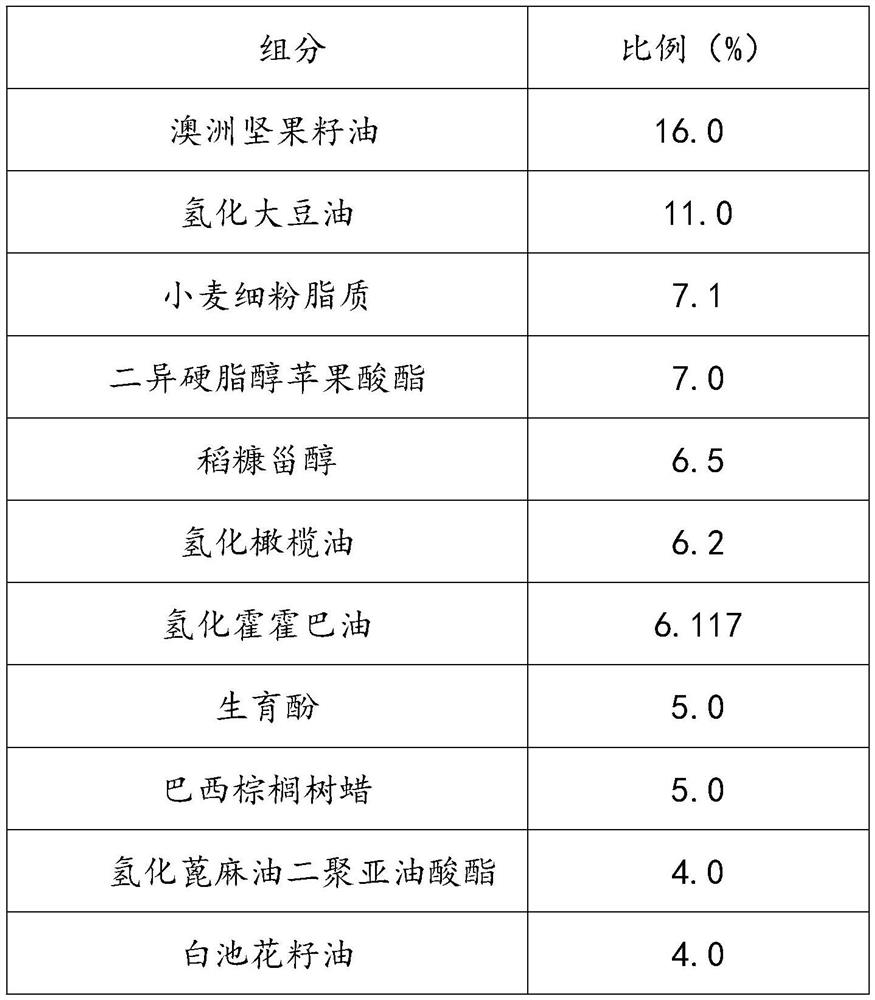

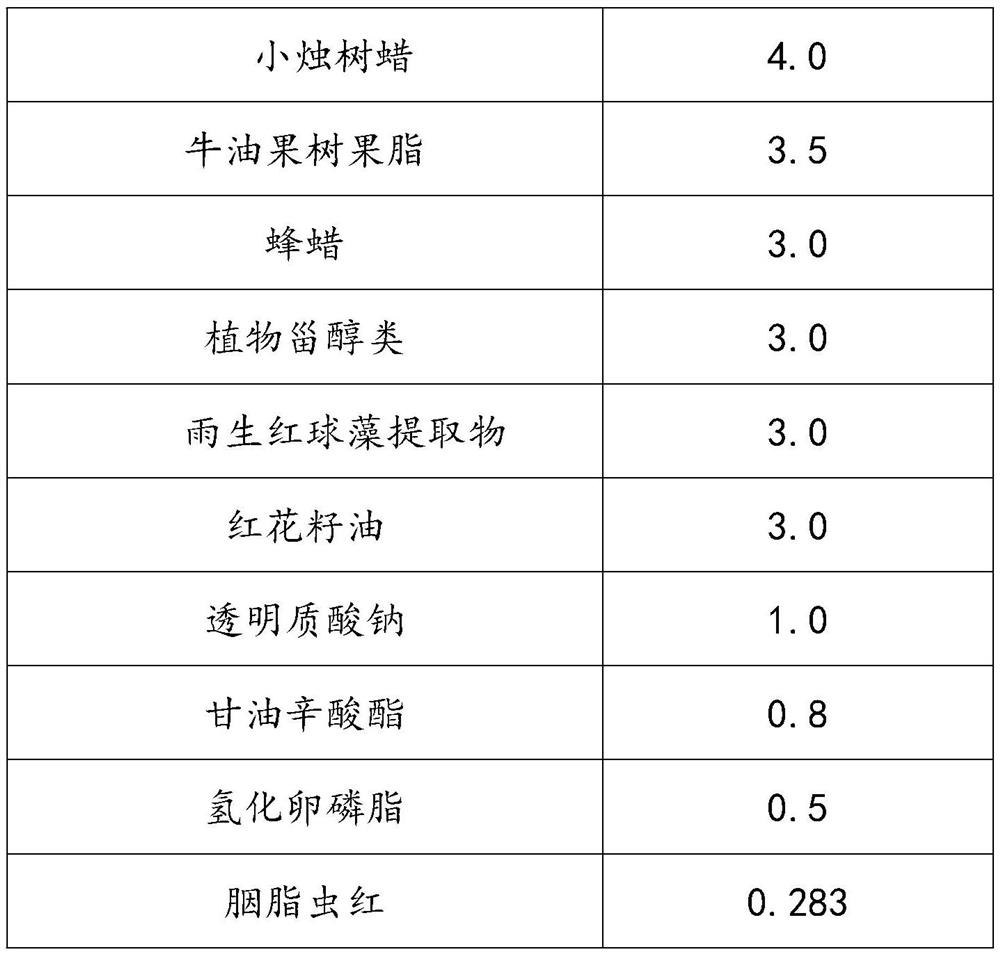

Astaxanthin-containing natural antioxidant composition for lips

PendingCN111840141AInhibit peroxidative damagePromote blood circulationCosmetic preparationsMake-upAstaxanthinBiology

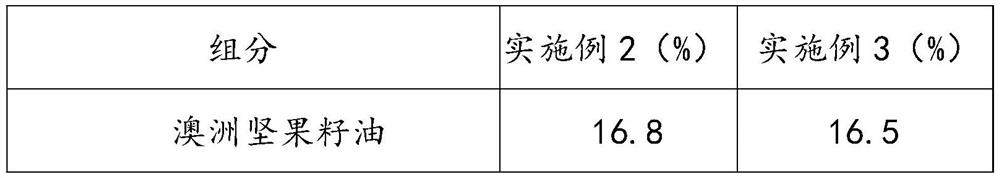

The invention relates to an astaxanthin-containing natural antioxidant composition for lips. According to main points of the technical scheme, the astaxanthin-containing natural antioxidant composition for lips is prepared from the following components in percentage by mass: 50.0-70.0 percent of a skin conditioner, 11.0 to 16.5 percent of an emollient, 3.7 to 6.25 percent of an antioxidant, 9.0 to15.0 percent of a plastic forming agent, 3.0 to 5.25 percent of a softening and moistening agent, 0.75-1.65 percent of a humectant, and 0.2 to 0.35 percent of a coloring agent. The composition disclosed by the invention is prepared from a plurality of natural non-irritant functional components according to a specific ratio, is good in compatibility, reduces the product risk and is higher in safety performance; meanwhile, specific functional components are added, so that the composition can care fragile lips, keep moisture for a long time, inhibit lipid peroxidation damage of the lips, promoteblood circulation of the lips and beautify lip color when in use.

Owner:潘永宽

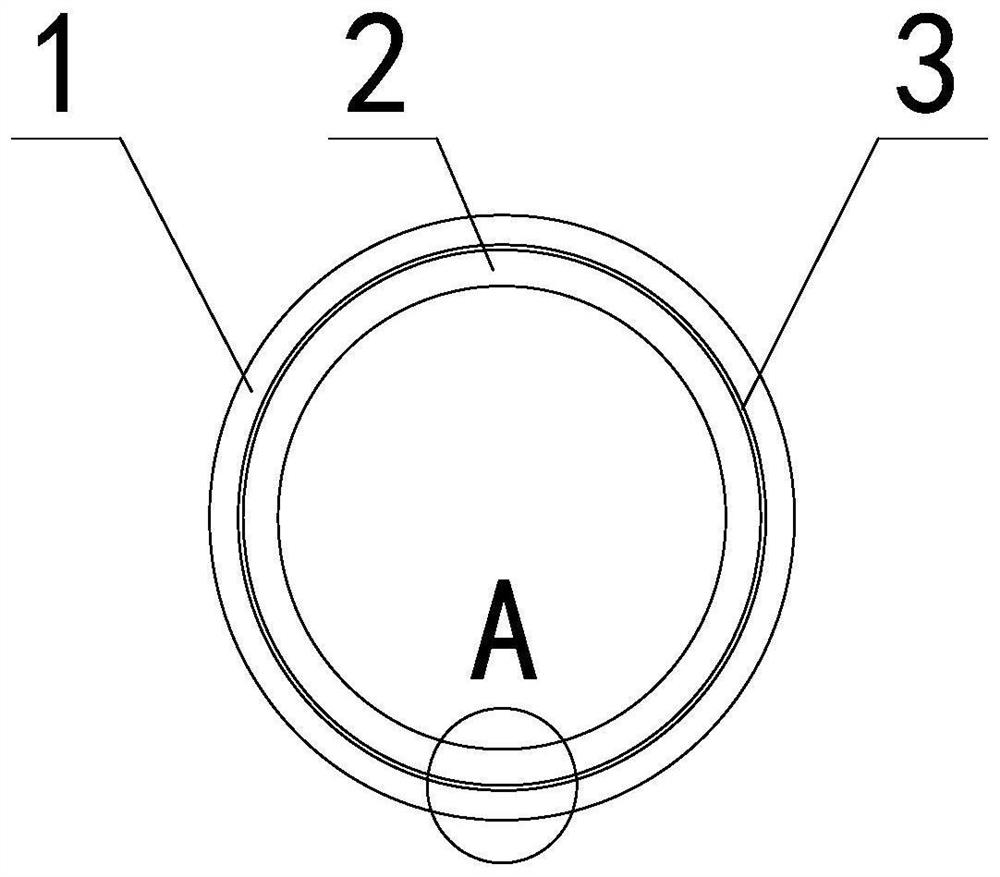

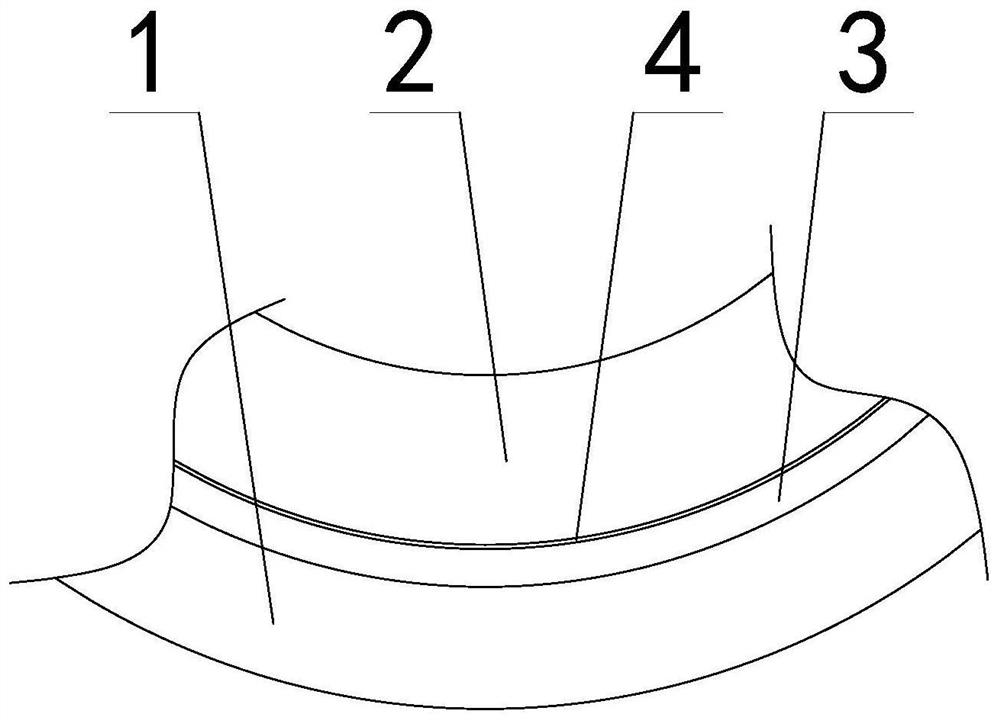

Engine cover assembly

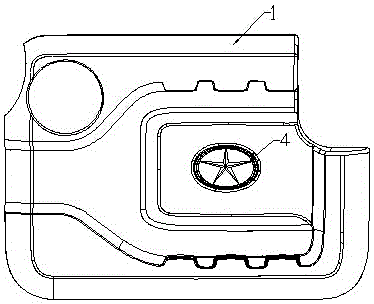

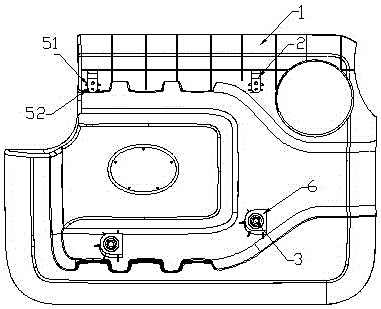

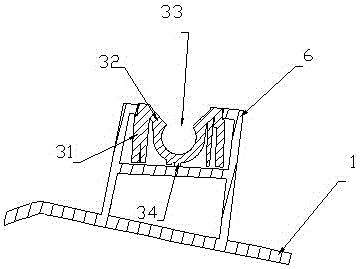

InactiveCN105065116AEasy to installHigh strengthMachines/enginesEngine componentsRubber ringEngineering

An engine cover assembly is composed of an engine cover body (1) and two rubber rings (3). Two mounting bases (6) are arranged on the inner surface of the engine cover body (1) and the rubber rings (3) are fixedly installed in the mounting bases (6). The engine cover assembly is characterized in that a decorating part (4) is further fixedly installed on the outer surface of the engine cover body (1). The strength of the mounting bases (6) on the engine cover body (1) is greatly improved. The rubber rings (3) can be installed conveniently and rapidly, and meanwhile the stability and disengagement prevention property of the rubber rings (3) are improved.

Owner:丹阳金城配件有限公司

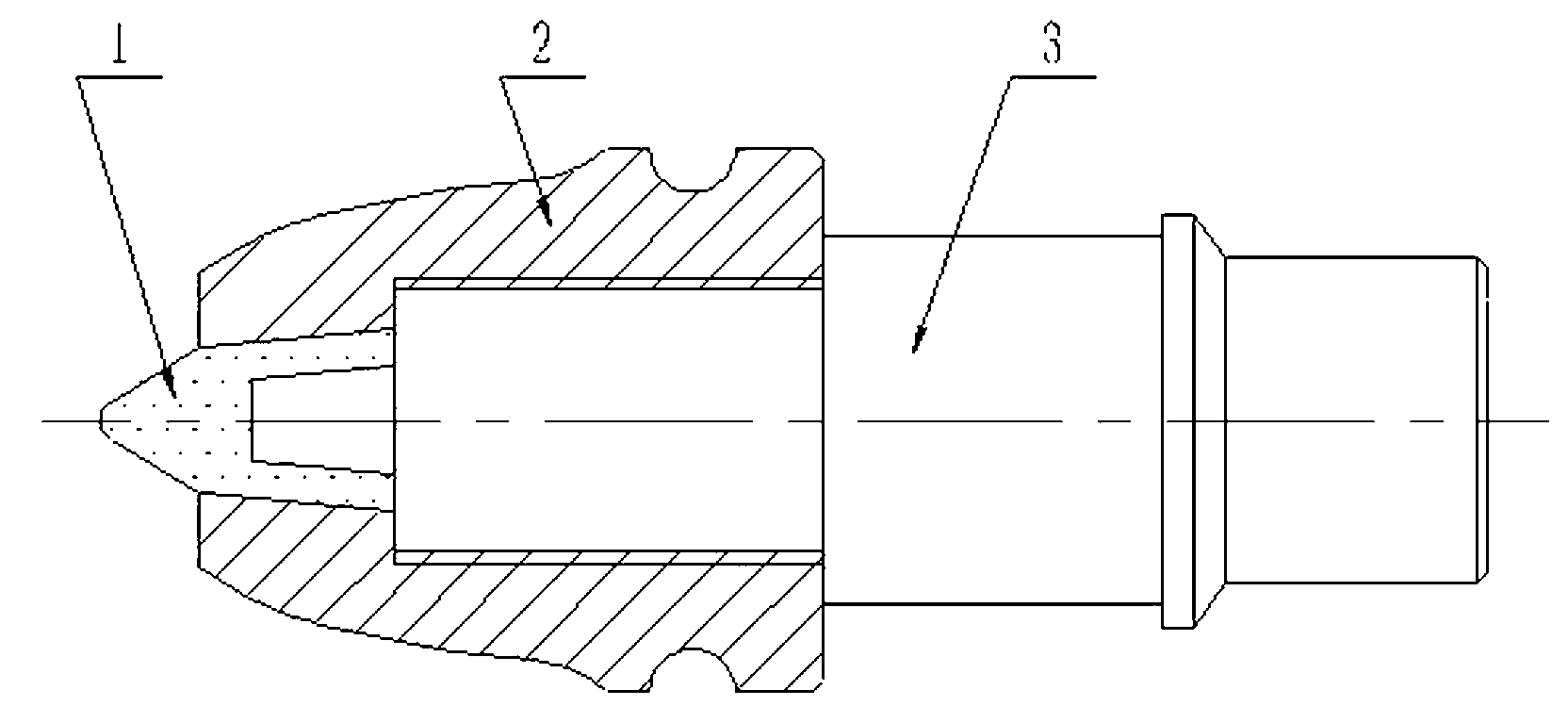

Anti-falling cutting pick with composite assembled structure

InactiveCN102996126BExtend your lifeImprove anti-shedding abilitySlitting machinesEngineeringStructural engineering

The invention discloses a high-performance anti-falling cutting pick with a composite assembled structure. The cutting pick comprises a cutting pick shank, a cutting pick head, and a protective fixing sleeve. One end of the cutting pick shank is a fixing end. The other end of the cutting pick shank and the cutting pick head form a taper connection through self-locking. The cutting pick head has an inner taper hole, and the cutting pick shank has an outer taper shank. The protective fixing sleeve and the cutting pick head also form a taper connection through self-locking. The cutting pick head has an outer taper shank, and the protective fixing sleeve has an inner taper hole. The protective fixing sleeve and the cutting pick shank are threadedly connected. With the cutting pick provided by the invention, cutting pick head anti-falling capacity and cutting pick service life can be improved, construction efficiency can be effectively improved, and construction cost can be reduced.

Owner:SHENYANG LIGONG UNIV

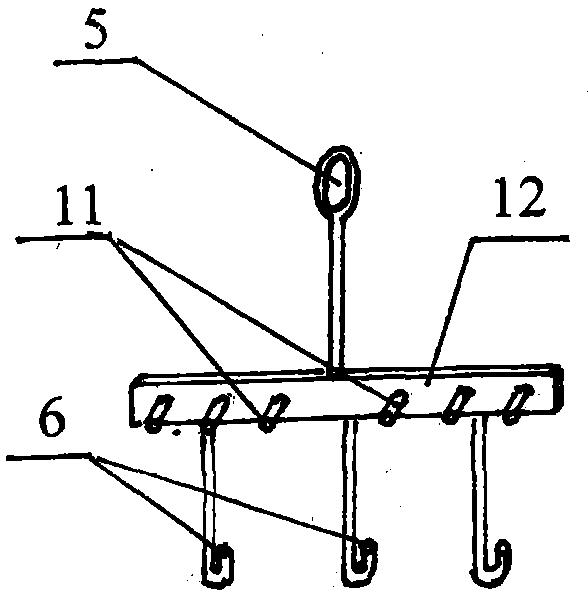

Stable thorn multi-pivot bonding hook frame

InactiveCN104138192AStop falling offIncreased resistance to sheddingKitchen equipmentDomestic articlesEngineering

The invention discloses a stable thorn multi-pivot hook bonding frame. The stable thorn multi-pivot hook bonding frame is characterized in that the lower end of a bonding body of a bonding hook is provided with a cross lever with thorns, the middle of a hook body is provided with a cross lever with supporting hook levers, the bonding body is pasted to a tile curtain wall, the thorns at the lower end of the bonding body are stabbed and inserted into a transverse tile gap formed by splicing two tiles to enhance the disengaging preventing capacity of the bonding hook, the supporting cross levers on the cross lever of the hook body are arranged on the cross lever of the bonding body in a pillowed mode, and the disengaging preventing capacity of the bonding hook is further improved.

Owner:SUZHOU HUAZONG TEXTILE NEW MATERIAL TECH CO LTD

Moisture-absorbing easy-to-scrub coating layer and preparation method thereof

The invention discloses a moisture-absorbing easy-to-scrub coating layer and a preparation method thereof, and belongs to the technical field of coating layer materials. The preparation method comprises the steps: stirring nano bismuth oxide subjected to hydrogen plasma treatment and 3-aminopropyltrimethoxysilane in water to prepare modified nano bismuth oxide, adding the modified nano bismuth oxide and carboxymethyl cellulose into polyethylene glycol, uniformly mixing, uniformly smearing, heating to prepare a bottom coating layer, and carrying out stirring reaction of 4,4-dihydroxydiphenylamine and 3,5-dichlorobenzoic acid in a sodium hydroxide solution to prepare a diphenylamine-benzoic acid copolymer; uniformly mixing the diphenylamine-benzoic acid copolymer and polyethylene glycol, and carrying out film scraping to prepare a surface coating layer; putting the surface coating layer into a 1,4-dichlorobutane alkaline solution to prepare a modified surface coating layer; and adhering the modified surface coating layer to the bottom coating layer, and heating, to obtain the moisture-absorbing easy-to-scrub coating layer. The moisture-absorbing easy-to-scrub coating prepared by the preparation method has excellent moisture absorption, and dirt on the surface is easy to scrub.

Owner:黄勤

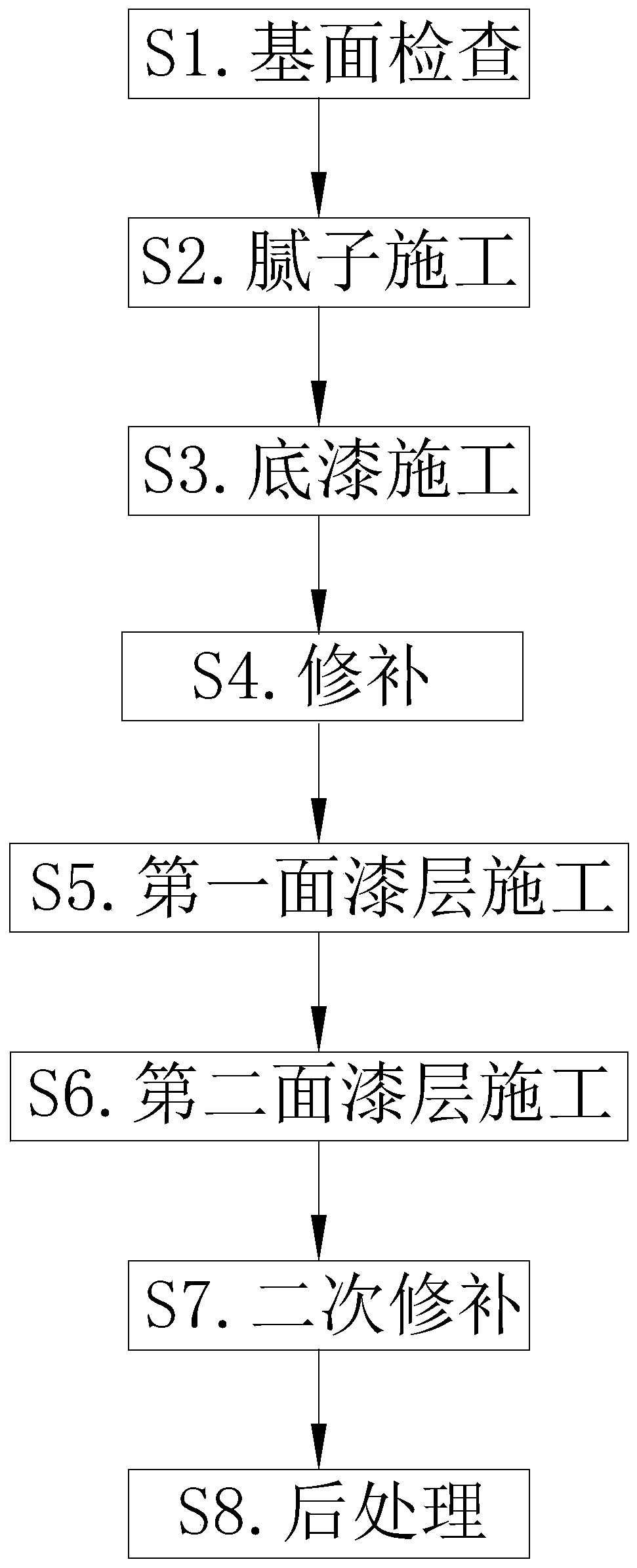

Method for improving environment-resistant performance of surface paint layer of titanium alloy part

PendingCN112474241AImprove environmental resistanceGuaranteed integrityPretreated surfacesMetallic material coating processesTitaniumTitanium alloy

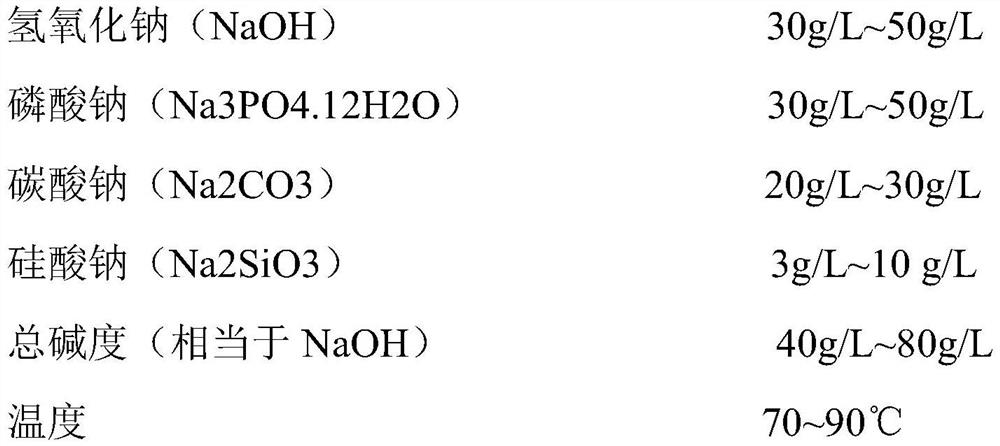

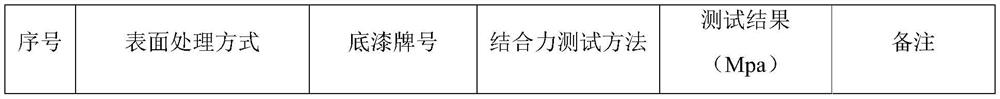

The invention belongs to the technical field of surface treatment of titanium alloys, and relates to a method for improving environment-resistant performance of a surface paint layer of a titanium alloy part. The method is mainly a solution for solving problems such as paint layer falling and cracking when the titanium alloy part for surface paint coating is used actually and environmental assessment is conducted according to standard such as GJB150. The process flow of the method comprises the following steps of sand blowing / deoiling / passivating / drying / paint coating, so that the surface energy of a titanium alloy matrix is increased effectively, and the anti-falling ability of the paint layer in a temperature and humidity alternating environment is improved, and thereby, the environment-resistant performance of the surface paint layer of the titanium alloy is further improved. The method improves the service performance of a paint coating product of the titanium alloy and lowers the later maintenance cost of the product. The method is convenient to operate and suitable for being industrially produced and applied on a large scale.

Owner:ZHENGZHOU AIRCRAFT EQUIP

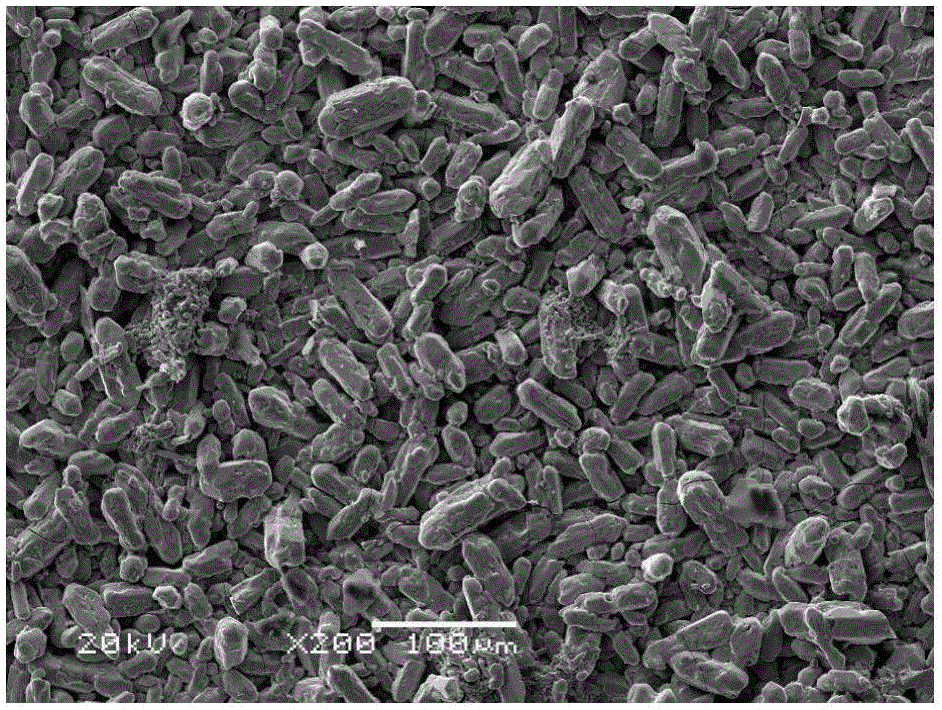

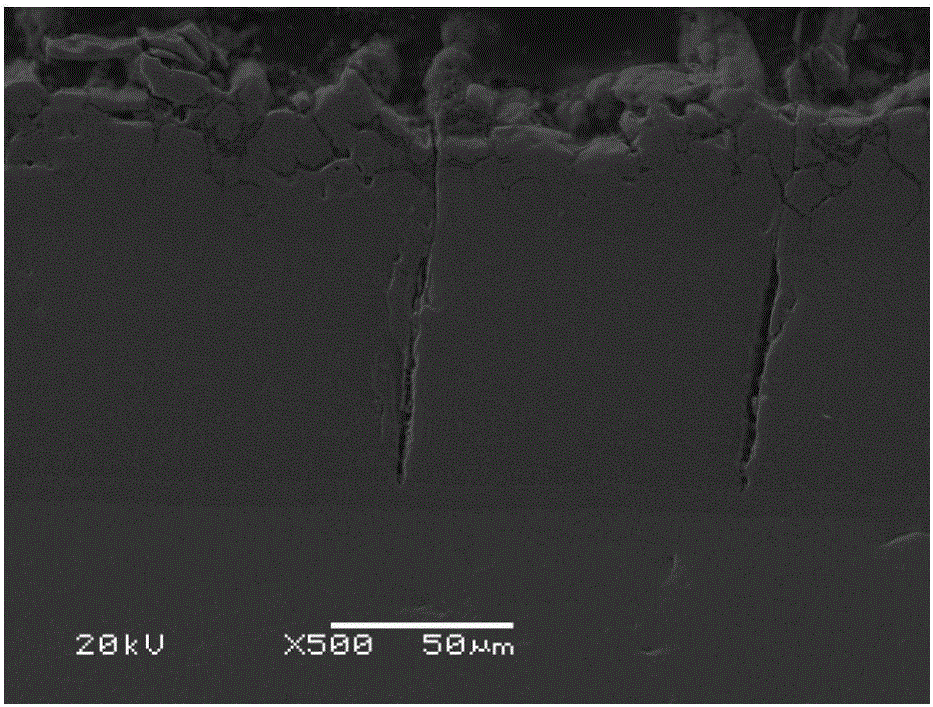

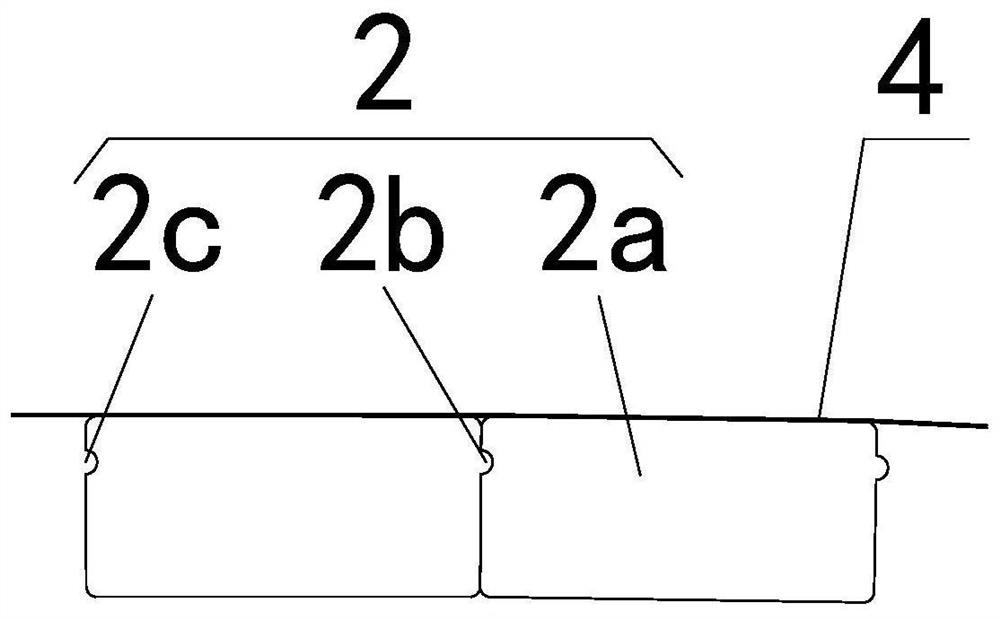

Ultrafine ceramic and metal composite pipe and preparation method thereof

PendingCN110864166AReduce areaLow difficulty in processing and productionCorrosion preventionPipe protection against corrosion/incrustationAdhesiveShock resistance

The invention relates to an ultrafine ceramic and metal composite pipe which comprises a metal pipe body, wherein the diameter of the metal pipe body is less than 10 cm; a ceramic pipe is arranged inthe metal pipe body in a sleeving manner; the ceramic pipe is fixed with the metal pipe body through an inorganic layer; the ceramic pipe is formed through splicing multiple tiles; and every two adjacent tiles are glued and fixed through a high temperature and corrosion resistant adhesive. The invention further provides a preparation method of the ultrafine ceramic and metal composite pipe. The preparation method comprises the following steps: 1, manufacturing tiles; 2, manufacturing a ceramic pipe; and 3, manufacturing the composite pipe. The ceramic pipe manufactured in the step 2 is inserted in the metal pipe body to ensure seamless gluing of the ceramic pipe and the inorganic layer, and after the inorganic layer is solidified, the ultrafine ceramic and metal composite pipe is manufactured. The ultrafine ceramic and metal composite pipe can resist corrosion, wear and high temperature, is high in shock resistance, and is simple in producing process and low in cost.

Owner:襄阳慧通电力科技有限公司

High temperature resistant baffle door and manufacturing method thereof

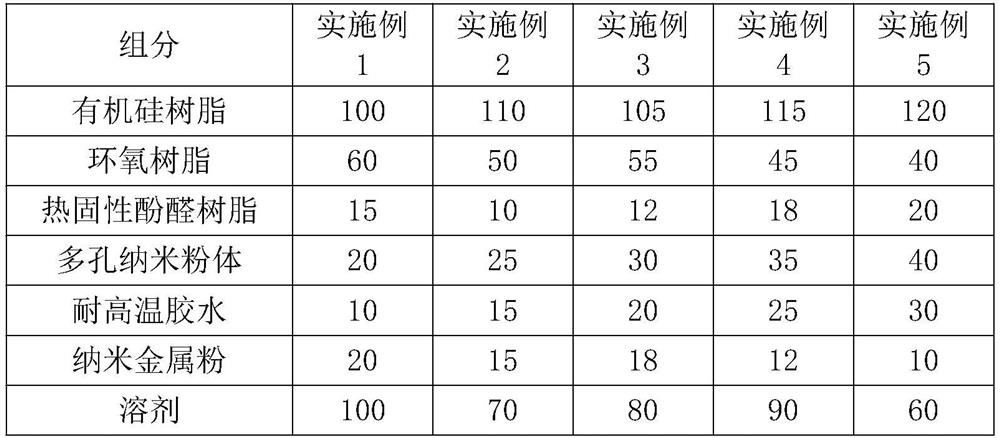

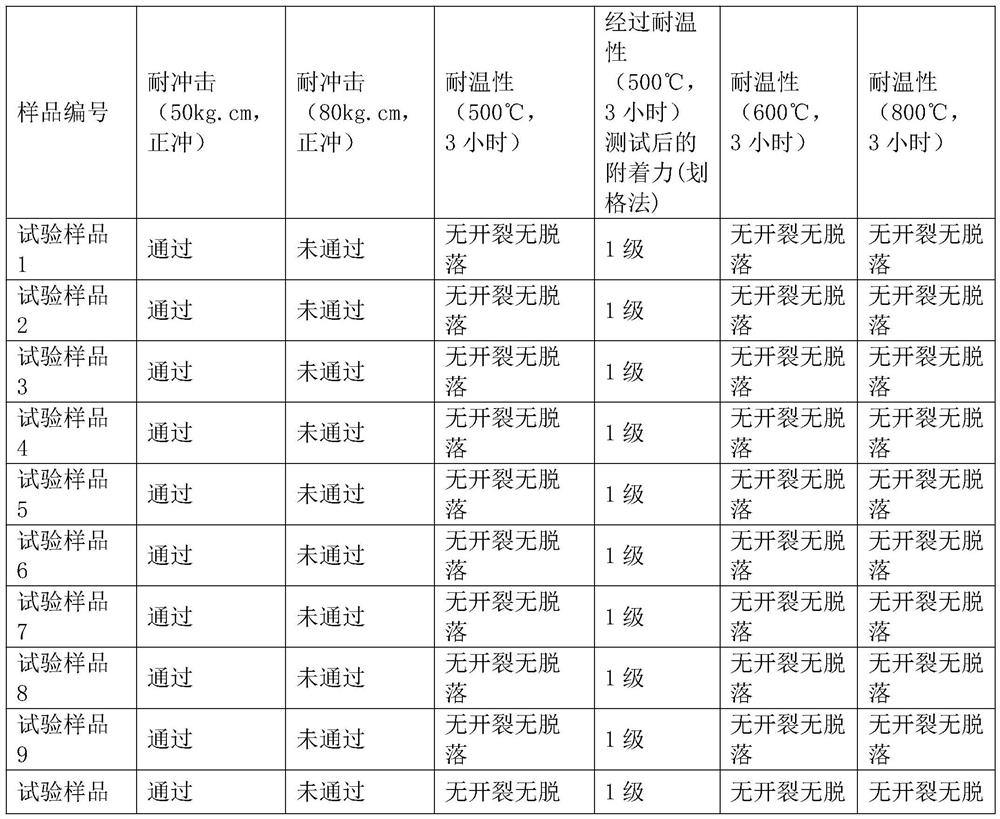

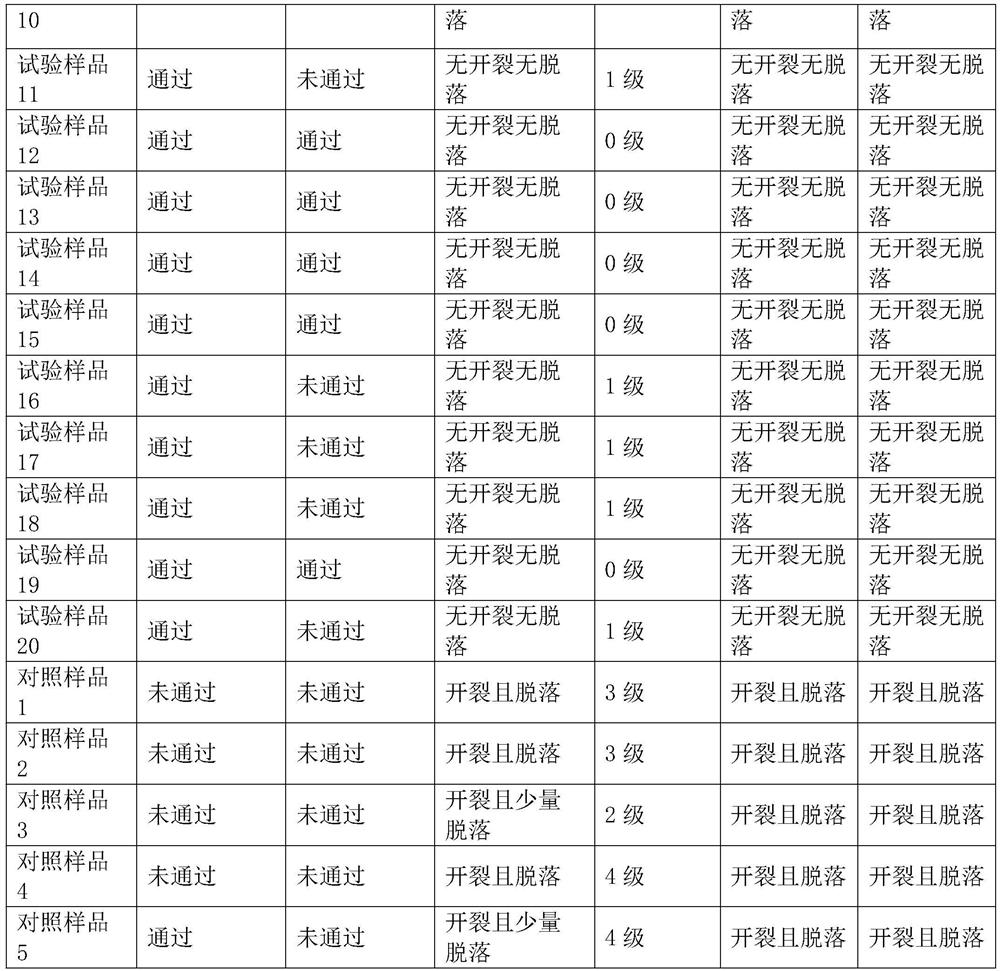

ActiveCN110305582BImprove high temperature resistancePrevent sintering shrinkageFireproof paintsEpoxy resin coatingsEpoxyAdhesive glue

The invention discloses a high temperature resistant baffle door and a manufacturing method thereof, and relates to the technical field of flue gas desulfurization equipment. The technical gist is: a high-temperature-resistant baffle door, including a door body and a high-temperature-resistant coating coated on the surface of the door body. The raw materials of the high-temperature-resistant coating include the following components in parts by weight: silicone resin 100 ‑120 parts; 40‑60 parts of epoxy resin; 10‑20 parts of thermosetting phenolic resin; 20‑40 parts of porous nano powder; 10‑30 parts of high temperature resistant glue; 10‑20 parts of nano metal powder; 60‑100 parts of solvent The pores of the porous nanometer powder are loaded with silicon dioxide airgel, and the diameter of the pores of the porous nanometer powder is larger than the particle size of the silicon dioxide airgel. The high temperature resistant baffle door has the advantages of good high temperature resistance, and the coating is not easy to crack and fall off.

Owner:ZHEJIANG TUNA ENVIRONMENTAL SCI & TECH

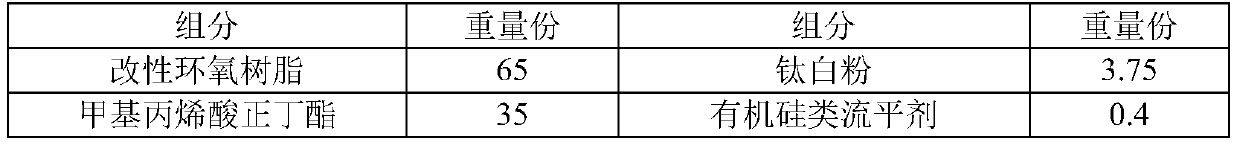

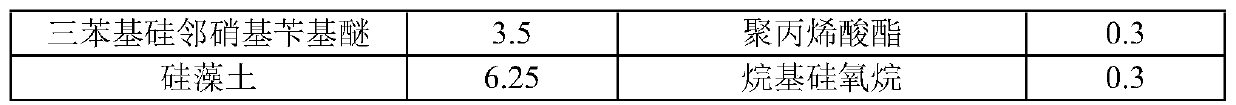

LED-UV solvent-free spraying primer and method for coating thermosensitive substrates such as paper, solid wood and plastic with LED-UV solvent-free spraying primer

ActiveCN111205685AImprove physical and chemical propertiesImproved wet adhesionNon-fibrous pulp additionLiquid surface applicatorsFiberSolid wood

The invention relates to LED-UV solvent-free spraying primer and a method for coating thermosensitive substrates such as paper, solid wood and plastic with the LED-UV solvent-free spraying primer. Theprimer is prepared from the following components in parts by weight: 55-75 parts of modified epoxy resin, 30-40 parts of n-butyl methacrylate, 2-5 parts of triphenyl silicon o-nitrobenzyl ether, 5-15parts of filler, 0.2-0.6 parts of a leveling agent, 0.1-0.5 parts of a dispersing agent and 0.1-0.5 parts of an antifoaming agent. The modified epoxy resin is composite fiber / phenolic aldehyde / epoxyresin. The coating method comprises the following steps: A1, preparing composite fibers; A2, preparing composite fiber / phenolic aldehyde / epoxy resin; A3, mixing the base materials; A4, mixing the auxiliary agents; and A5, preparing a finished product. The paint has the effect of improving the anti-falling performance of the paint layer.

Owner:成都迪泰化工有限公司

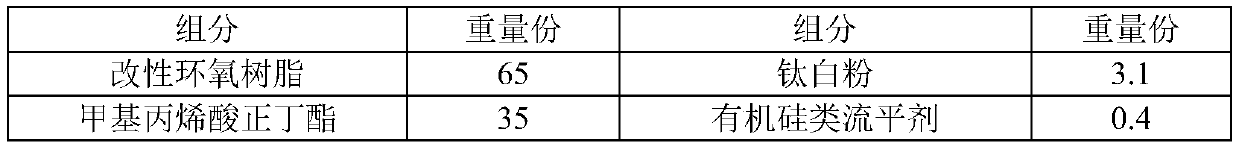

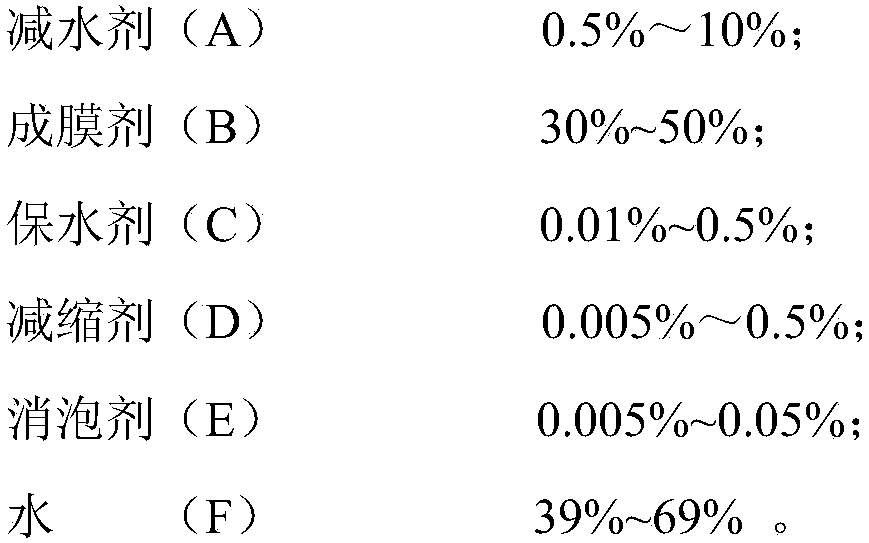

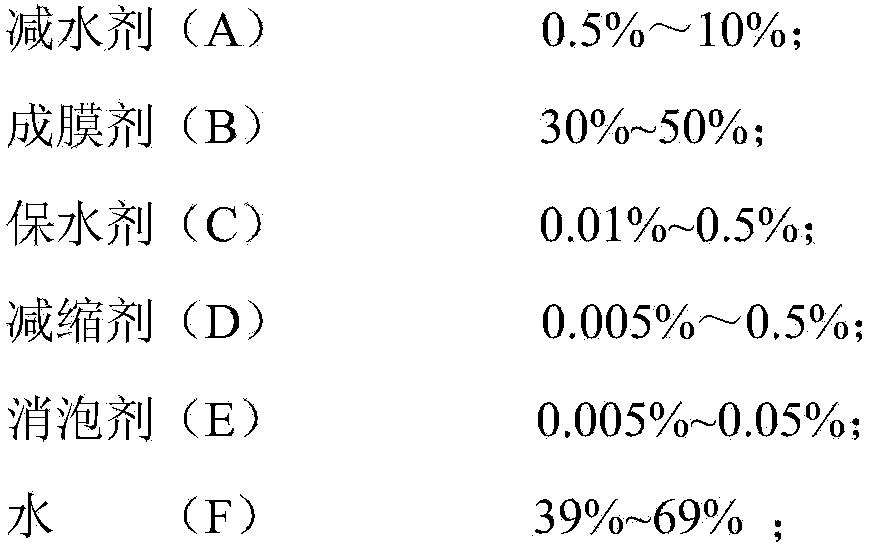

Special mortar compacting agent suitable for improving durability of PCCP protective layer mortar and preparation method thereof

The invention discloses a special-purpose mortar compacting agent for improving PCCP protective layer mortar endurance and a preparation method thereof. The special-purpose mortar compacting agent comprises, by weight, 0.5-10% of a water reducer, 30-50% of a film forming agent, 0.01-0.5% of a water-retaining agent, 0.005-0.5% of a shrinkage reducing agent, 0.005-0.05% of an antifoaming agent and 39-69% of water. The preparation method comprises adding water into a mixer, starting the mixer, after the mixer operates smoothly, orderly and slowly adding all ingredients into the mixer and after the materials are fully dissolved, carrying out uniform stirring. The special-purpose mortar compacting agent can be used in PCCP protective layer mortar, can obviously improve PCCP protective layer mortar permeability resistance, cracking resistance, shedding resistance, erosion resistance and freezing resistance, can improve PCCP pipe endurance and can further accelerate promotion and use of a PCCP pipe in large-scale water conveying engineering construction. The preparation method has simple processes, realizes a low cost, is environmentally friendly and is an effective economical technical method for ensuring PCCP pipe endurance.

Owner:安徽瑞和新材料有限公司

Anti-shedding agent as well as preparation method and application thereof

ActiveCN114479487AIncreased resistance to sheddingReduce sheddingBuilding insulationsPolyethylene oxideEthylene oxide

The invention discloses an anti-shedding agent as well as a preparation method and application thereof. The anti-shedding agent comprises the following raw materials: styrene butadiene rubber, polyethylene oxide, styrenated phenol, resin, alkyl ammonium chloride and a nitrogen-containing aromatic compound. The preparation method of the anti-shedding agent comprises the following steps: uniformly mixing the materials, mixing, extruding and granulating to obtain the anti-shedding agent. The anti-shedding agent disclosed by the invention is granular, is used in airport asphalt, can remarkably improve the adhesion strength of the asphalt and improve the anti-shedding performance, and has relatively strong adaptive capacity to a high-temperature wake flow environment of an airplane.

Owner:CHINA PETROLEUM & CHEM CORP +1

A preparation method of composite anti-corrosion, wear-resistant and high-temperature-resistant pipe

ActiveCN110939798BImprove impact resistanceAccelerated corrosionCorrosion preventionPipe protection against corrosion/incrustationComposite ceramicAdhesive

The invention relates to a method for preparing a composite anticorrosion, wear-resistant, and high-temperature-resistant pipe, which comprises the following steps: 1) making porcelain tiles: according to the proportion, select raw material powders with a particle size of 50 μm, mix them evenly, and mix the evenly mixed The powder is made into a green body of ceramic chips, and then sintered at high temperature to make ceramic chips; 2) Making ceramic tubes: according to the size of the pipe diameter, select an appropriate number of ceramic chips and splice them into a circular ceramic ring. Bonding with a high temperature and corrosion resistant adhesive, and then bonding the ceramic ring with a high temperature and corrosion resistant adhesive to form a ceramic tube; 3) Prepare a composite tube: coat a layer of inorganic layer in the metal tube body, and When it is not solidified, insert the ceramic tube into the metal tube body to ensure the seamless bonding of the ceramic tube and the inorganic layer. After the inorganic layer is solidified, a composite anti-corrosion, wear-resistant, and high-temperature-resistant tube is produced. The invention can process the metal composite ceramic tube with good corrosion resistance, wear resistance, high temperature resistance and impact resistance, and the production process is simple and the cost is low.

Owner:襄阳慧通电力科技有限公司

Anti-dropping ink and preparation method thereof

The invention discloses anti-dropping ink. The anti-dropping ink is prepared from the following raw materials in parts by weight: 10 to 20 parts of biphenol-A modified phenolic resin, 1 to 2 parts oftert-butyl-p-diphenol, 0.4 to 1 part of polysorbate, 0.1 to 0.2 part of barium naphthenate, 4 to 5 parts of nano silicon dioxide, and 3 to 5 parts of stearic acid. By adopting the anti-dropping ink, the dispersion compatibility between the nano silicon dioxide and the phenolic resin can be realized, the mechanical performance of the ink can be improved, the added phenolic resin has good viscosity,and the anti-dropping performance of a finished product can be effectively improved.

Owner:安徽徽合台智能科技有限公司

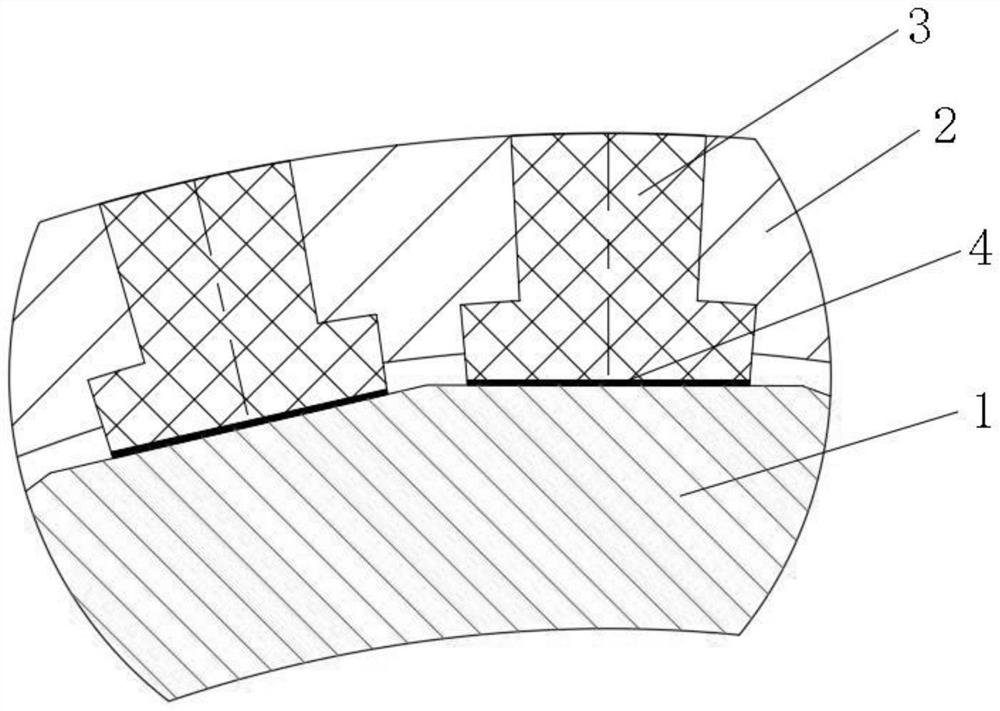

A kind of grinding roller sleeve and its manufacturing method

ActiveCN110813433BLarge wear surface areaGuaranteed firmnessFoundry mouldsFoundry coresCeramic particleCermet

The invention relates to a grinding roller sleeve and a manufacturing method thereof. The grinding roller sleeve comprises a grinding roller core, a metal roller sleeve, metal ceramic blocks and adjusting gaskets, wherein the axial sections of the grinding roller core and the metal roller sleeve are of hollow circular truncated cone structures; the grinding roller core is arranged on the inner side of the metal roller sleeve; a plurality of embedding grooves are uniformly formed in the metal roller sleeve at intervals; the metal ceramic blocks matched with the embedding grooves in shape and size are embedded into the embedding grooves respectively; the adjusting gaskets are inserted into gaps between the metal ceramic blocks and the grinding roller core; and the abutting condition of the metal ceramic blocks and the grinding roller core is adjusted through the adjusting gaskets. The grinding roller sleeve is obtained in a mechanical combination mode; a wear-resistant material of the grinding roller sleeve occupies a large wear surface area, and is anti-falling; ceramic particles are uniformly distributed; and the defects of a grinding roller sleeve manufactured through a method inthe prior art are effectively overcome.

Owner:上海电气上重碾磨特装设备有限公司

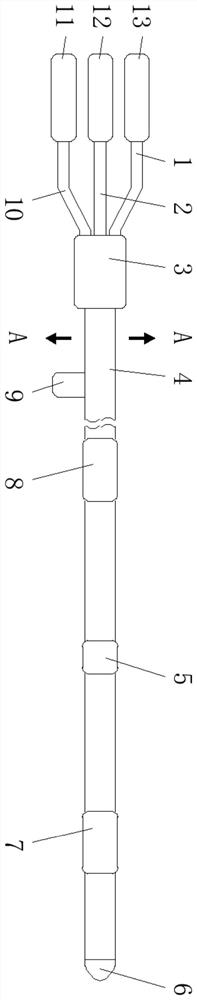

Double-balloon catheter device for gastrointestinal anastomosis

InactiveCN112274703ANo painGood treatment effectBalloon catheterMulti-lumen catheterBalloon catheterGastrointestinal anastomosis

The invention provides a double-balloon catheter device for gastrointestinal anastomosis. The device comprises a first balloon infusion tube, a positioning balloon infusion tube, a catheter shell, a pressure-resistant layer and a second balloon infusion tube, wherein a first balloon infusion tube, a positioning balloon infusion tube and a second balloon infusion tube are installed on the inner wall of the wire bundling ring, a first balloon, a positioning balloon and a second balloon are installed on the outer wall of the catheter shell, and the first balloon, the positioning balloon and the second balloon are sequentially arranged from left to right; a surface of the first balloon and the surface of the second balloon are made of the same material, and the surface material of the first balloon and the surface material of the second balloon each comprise a compression-resistant layer, a reinforcing layer and a protective layer. A patient does not feel pain in use, the transverse intestine can be well fixed, meanwhile, the balloon has good size stability and mechanical property, it can be guaranteed that work is safely and stably conducted, and practicability is high.

Owner:浙江桐轩医疗科技有限公司

Composite corrosion-resistant wear-resistant high-temperature-resistant pipe

PendingCN110873240AReduce areaLow difficulty in processing and productionCorrosion preventionPipe protection against corrosion/incrustationAdhesiveCorrosion resistant

The invention relates to a corrosion-resistant wear-resistant high-temperature-resistant pipe. The corrosion-resistant wear-resistant high-temperature-resistant pipe comprises a metal pipe body, a ceramic pipe body is sleeved with the metal pipe body, and the ceramic pipe body and the metal pipe body are fixed with an inorganic layer. The ceramic pipe body is formed by splicing a plurality of ceramic slices, and every two adjacent ceramic slices are fixedly bonded through a high-temperature-resistant corrosion-resistant adhesive. The corrosion-resistant wear-resistant high-temperature-resistant pipe can be resistant to corrosion, wear and high temperature and high in impact resistance, the production process is simple, and the cost is low.

Owner:襄阳慧通电力科技有限公司

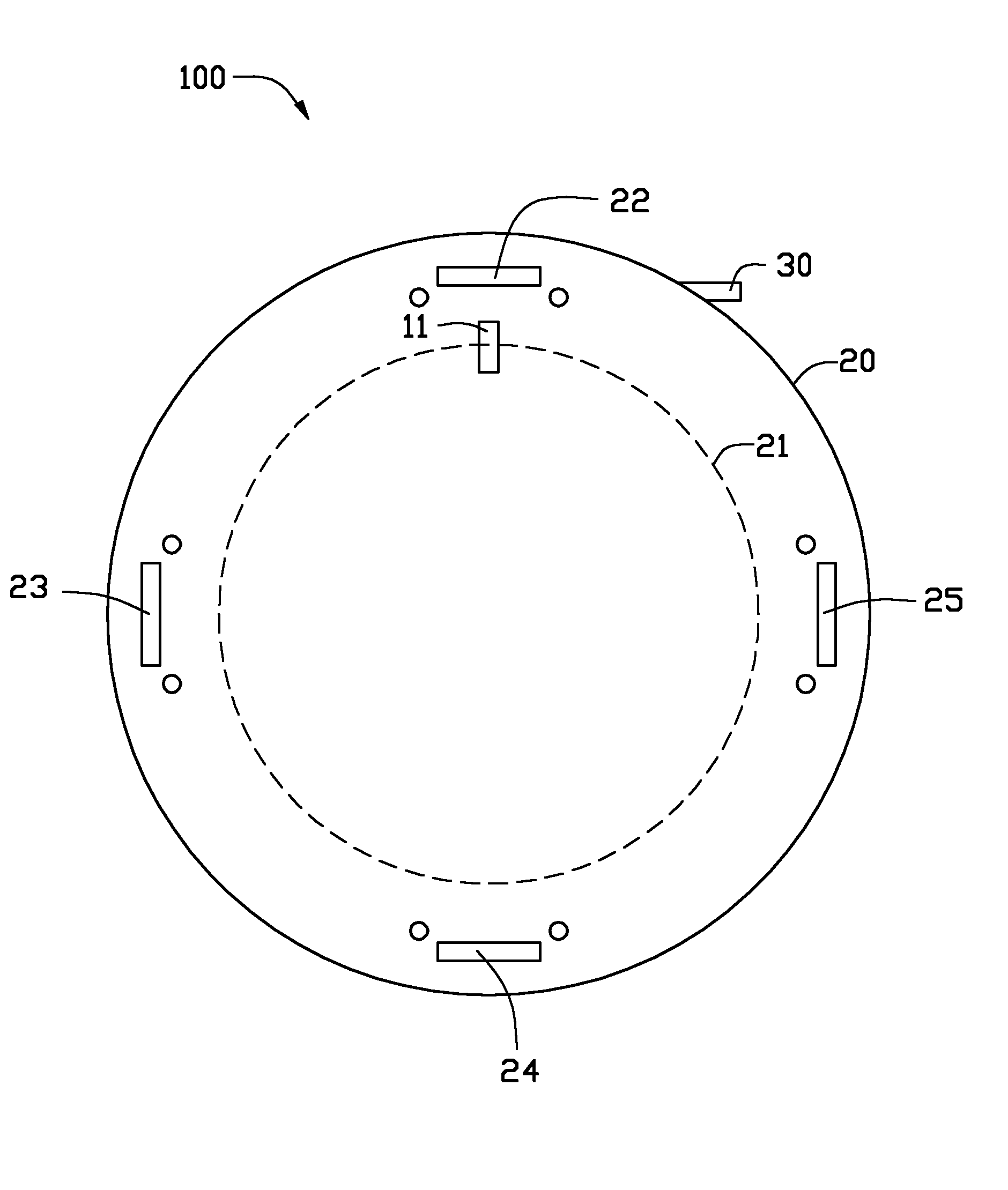

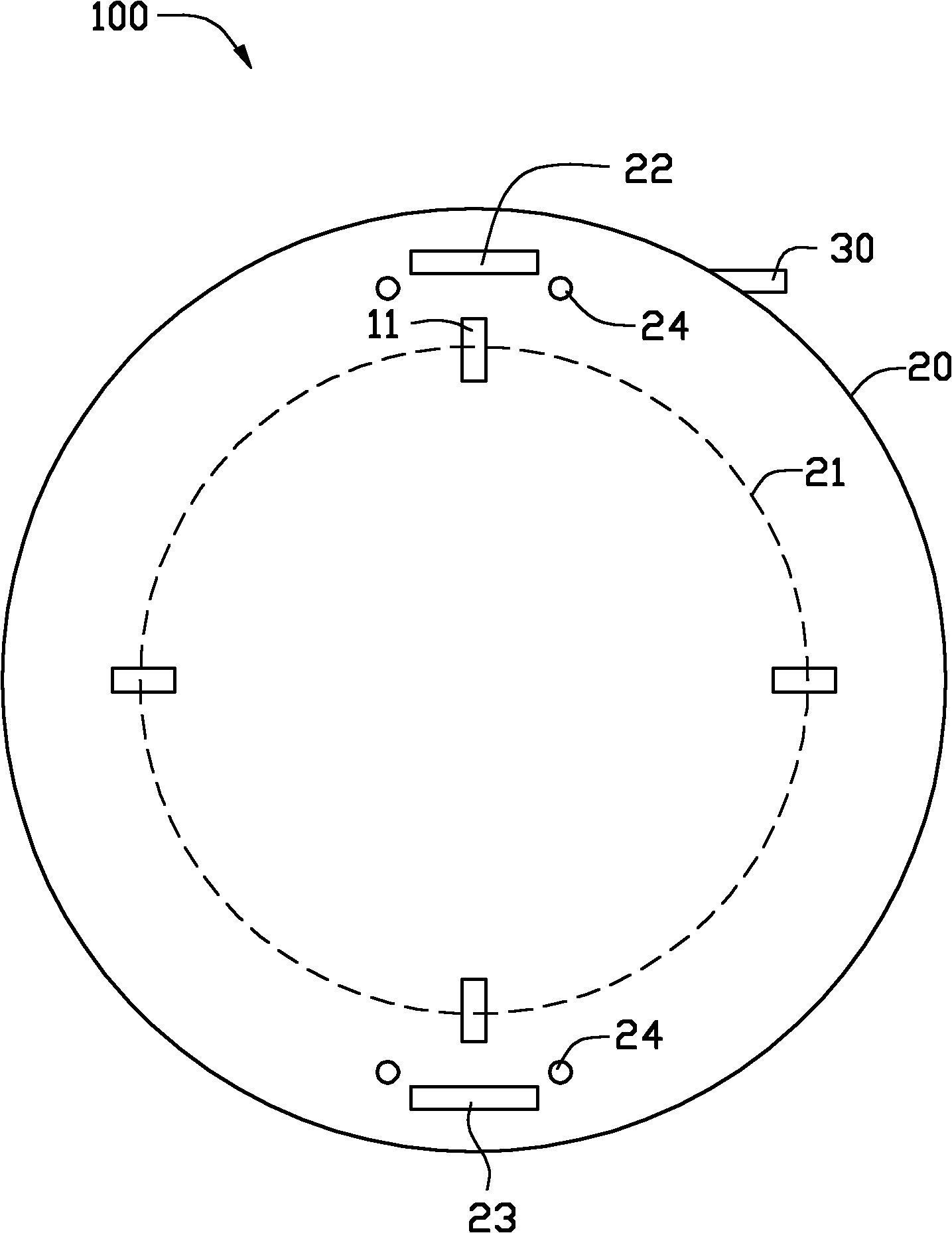

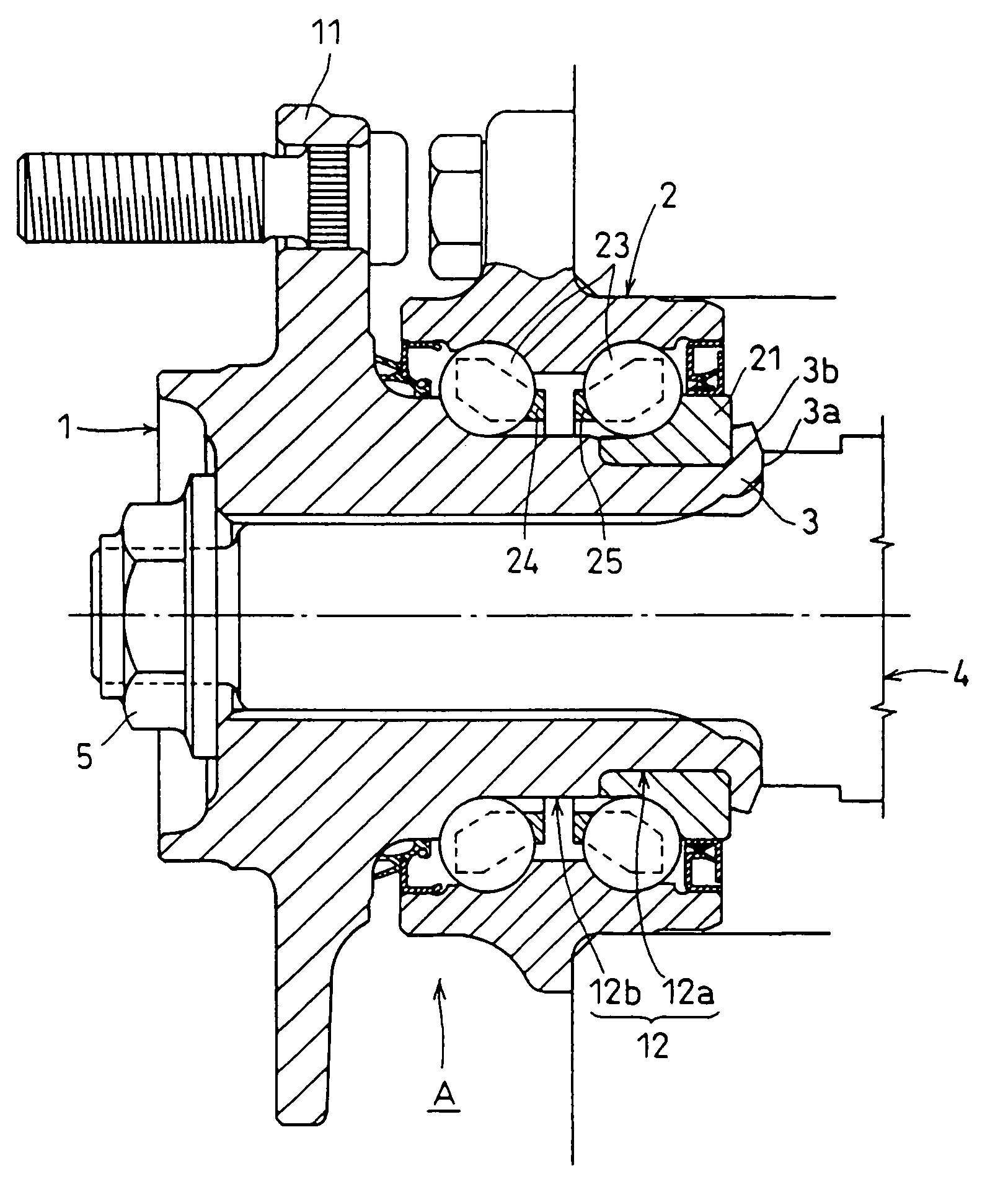

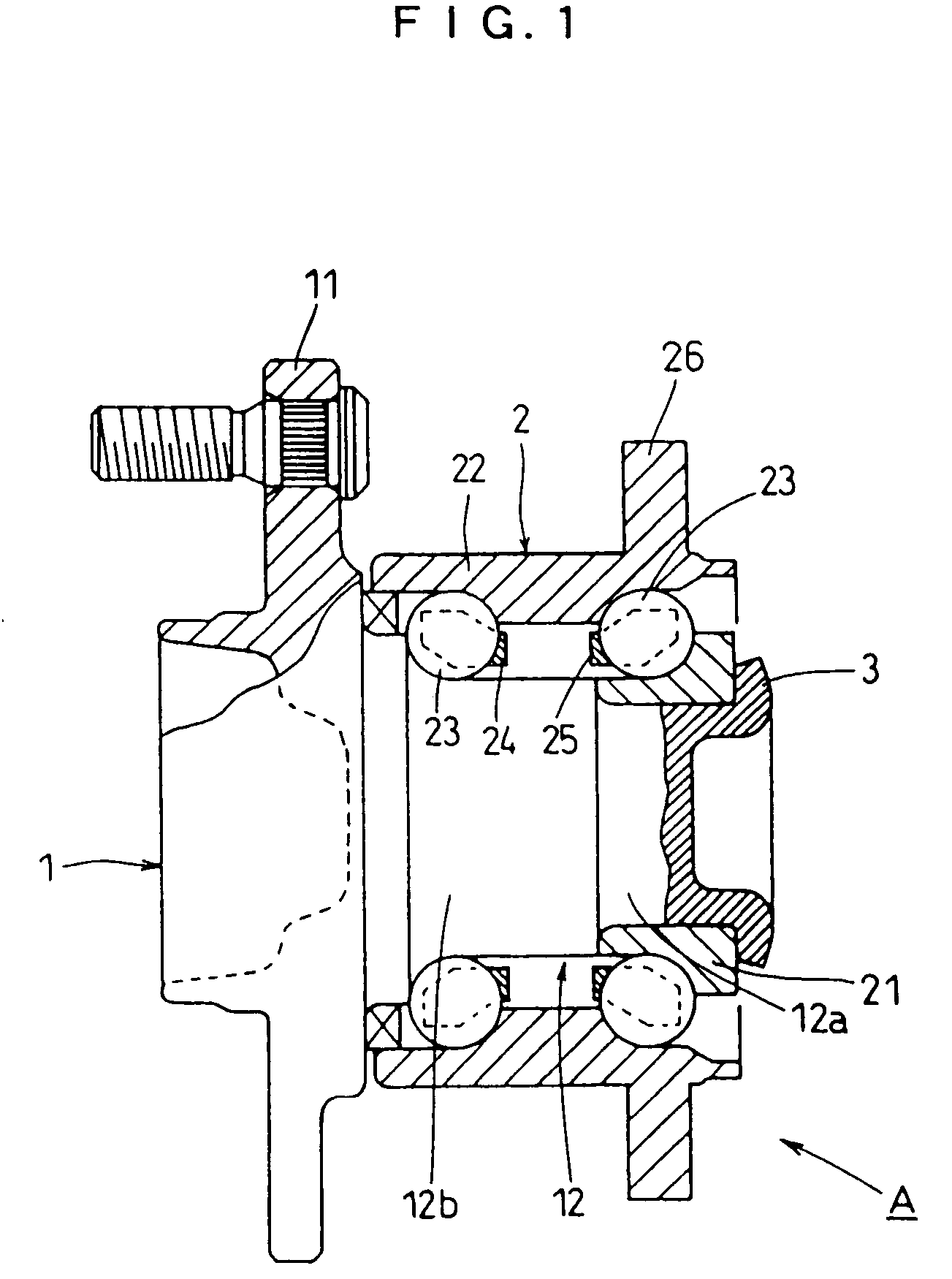

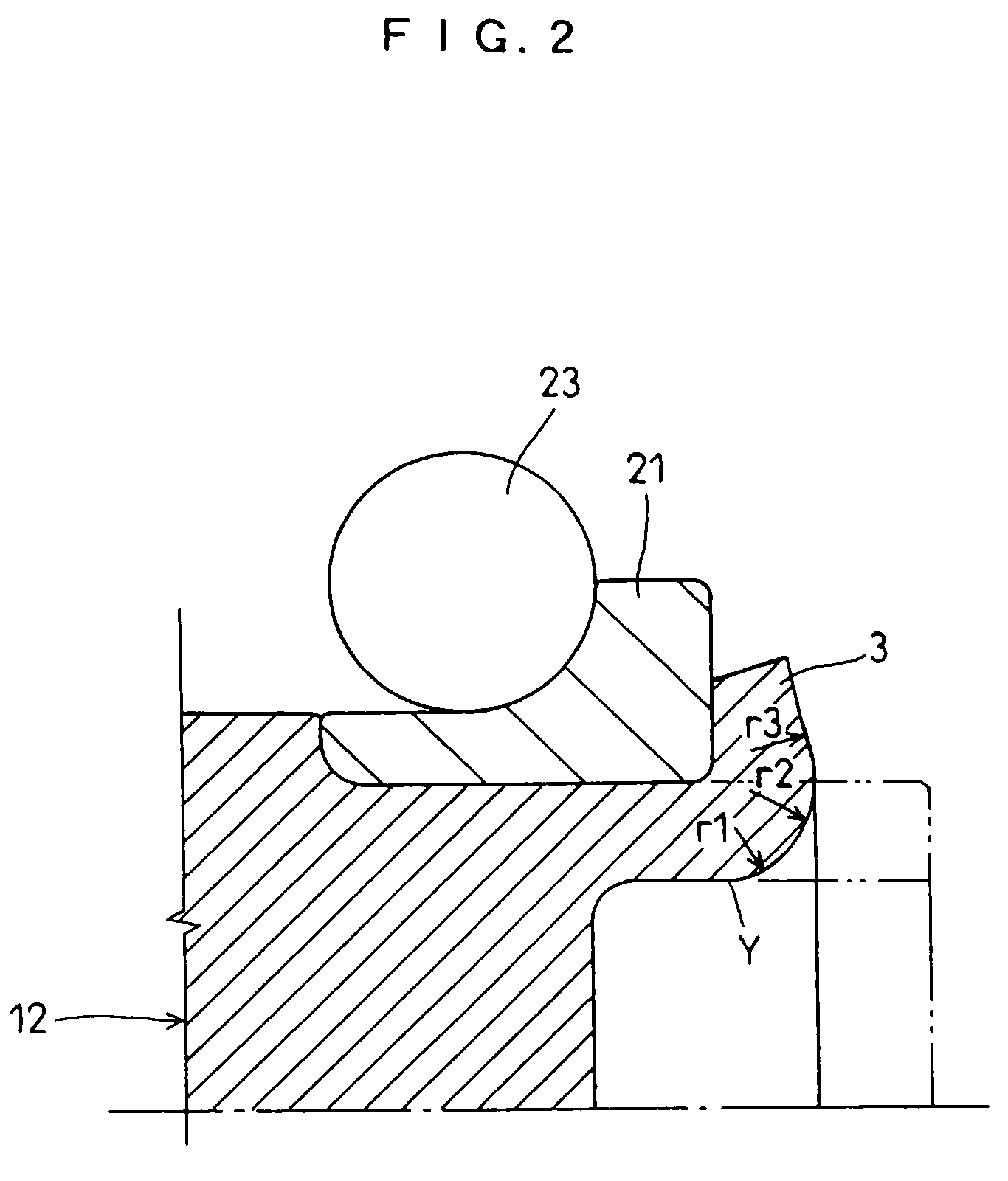

Bearing device

InactiveUS7104696B2Increased resistance to sheddingFacilitate decision-makingRoller bearingsHubsRolling-element bearingEngineering

A bearing device in which a rolling bearing is fitted on one axial end of a shaft and in which the one axial end of the shaft is caulked to fix the rolling bearing while preventing the same from coming out. The shape of the outer end face of the caulked portion is devised to maximize the resistance to the coming-out by the caulked portion.

Owner:KOYO SEIKO CO LTD

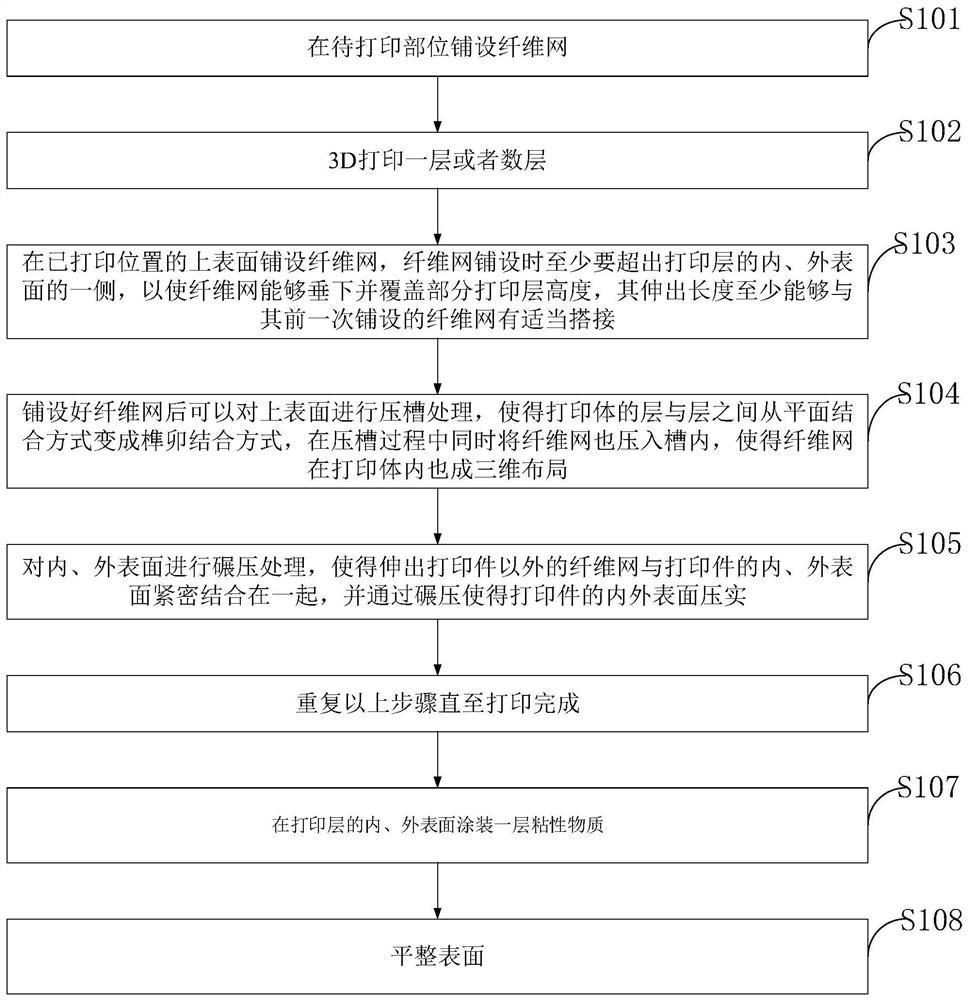

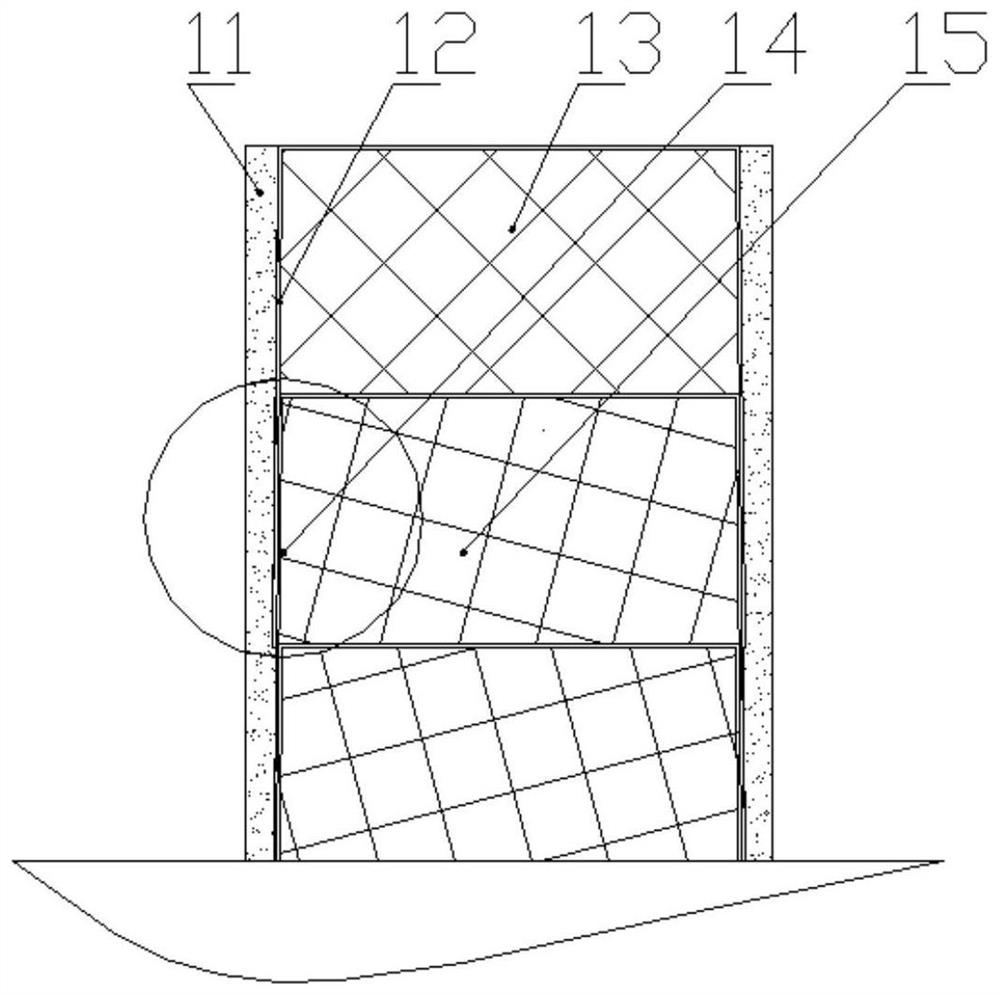

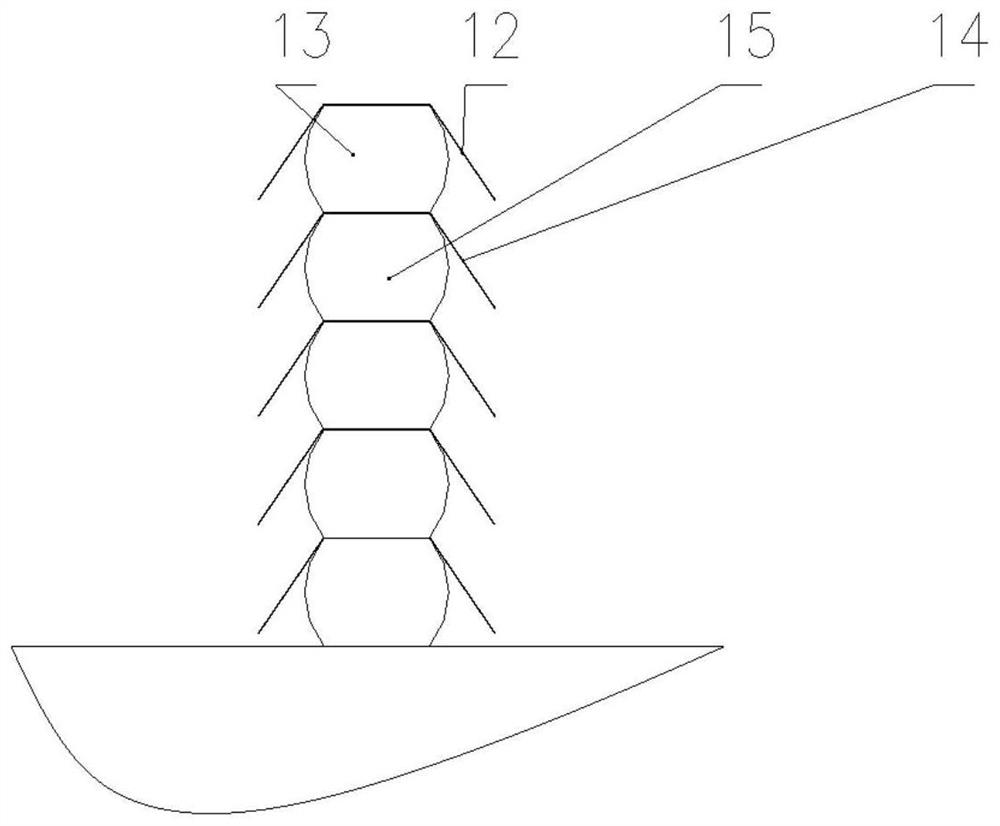

A 3D printing structure, manufacturing method and application

ActiveCN111319252BHigh strengthImprove toughnessAdditive manufacturing apparatus3D object support structuresFiberIndustrial engineering

The invention belongs to the technical field of 3D printing, and discloses a 3D printing structure and a manufacturing method thereof. A fiber web is laid between layers of a printed part, and at least one side of the fiber web exceeds the width of the printing layer and is closely combined with the material of the printing layer. Together, the fiber web that exceeds the printing layer can hang down to cover the printing layer where the fiber web is laid, and have an appropriate amount of overlap with the fiber web that is laid on the lower printing layer of the printing layer; The fiber web outside the print is tightly bonded to the inner and outer surfaces of the print. The invention enables the fibers in the 3D printing structure to form an orderly three-dimensional grid connection distribution in the three dimensions of length, width and height of the printing body, thereby greatly improving the bonding strength of the 3D printing body in the X and Y directions, and It also greatly improves the bonding quality and strength in the Z direction between layers, and its overall stiffness, toughness and bonding quality are also greatly improved.

Owner:姚胜南

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com