Method for improving environment-resistant performance of surface paint layer of titanium alloy part

A titanium alloy, environment-resistant technology, used in devices for coating liquids on surfaces, pretreatment surfaces, metal material coating processes, etc., can solve problems such as paint peeling, cracks, etc., to improve environmental resistance performance and easy operation. , the effect of increasing surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1 Sand blowing: the sand particle size is 40-70 mesh, the air pressure is 0.2MPa, and the distance between the nozzle and the part is 130mm.

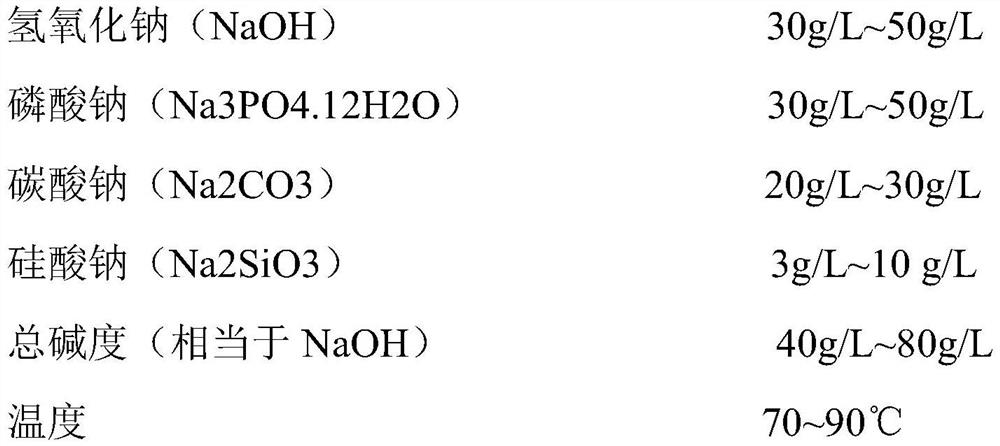

[0026] 2 Degreasing: Chemical degreasing solution components and process conditions are as follows:

[0027]

[0028]

[0029] 3 Passivation: passivation process within 4 hours after sand blowing. The composition of the passivation solution is: nitric acid (HNO3), the volume ratio: 45%, the operating temperature: 49-52° C., and the operating time: 35 minutes.

[0030] 4 Cleaning: The parts are washed in water at 30-60°C for 2-5 minutes. Then wash in running cold water at room temperature for 1 to 3 minutes.

[0031] 5. Drying: It is preferred to use dry and clean hot compressed air below 60°C to dry the parts.

[0032] 6 Painting: paint within 24 hours after passivation. The painting process is as follows: the distance between the nozzle of the spray gun and the surface of the part is 150-250mm, and the pressure of the ...

Embodiment 2

[0034] 1 Sand blowing: the sand particle size is 40 / 70 mesh, the air pressure is 0.3MPa, and the distance between the nozzle and the part is 200mm.

[0035] 2 Degreasing: Alkaline degreasing method

[0036] 3 Passivation: passivation process within 4 hours after sand blowing. The composition of the passivation solution is: nitric acid (HNO3), the volume ratio: 53%, the operating temperature: 49-52° C., and the operating time: 7 minutes.

[0037] 4 Cleaning: The parts are washed in water at 30-60°C for 2-5 minutes. Then wash in running cold water at room temperature for 1-3 minutes.

[0038] 5. Drying: It is preferred to use dry and clean hot compressed air below 60°C to dry the parts.

[0039] 6 Painting: paint within 24 hours after passivation. The painting process is a conventional painting process.

Embodiment 3

[0041] 1 Sand blowing: the sand particle size is 40 / 70 mesh, the air pressure is 0.5MPa, and the distance between the nozzle and the part is 300mm.

[0042] 2 Degreasing: Alkaline degreasing method

[0043] 3 Passivation: passivation process within 4 hours after sand blowing. The composition of the passivation solution is: nitric acid (HNO3), the volume ratio: 47%, the operating temperature: 51-54° C., and the operating time: 28 minutes.

[0044] 4 Cleaning: The parts are washed in water at 30-60°C for 2-5 minutes. Then wash in running cold water at room temperature for 1-3 minutes.

[0045] 5. Drying: It is preferred to use dry and clean hot compressed air below 60°C to dry the parts.

[0046] 6 Painting: paint within 24 hours after passivation. Conventional painting process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com