Special mortar compacting agent suitable for improving durability of PCCP protective layer mortar and preparation method thereof

A technology of compacting agent and protective layer, which is applied in the field of special mortar compacting agent and its preparation, can solve the problems of PCCP corrosion, poor mortar compactness, shedding durability, etc., and achieve the effect of improving impermeability, good compactness, and low risk of cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

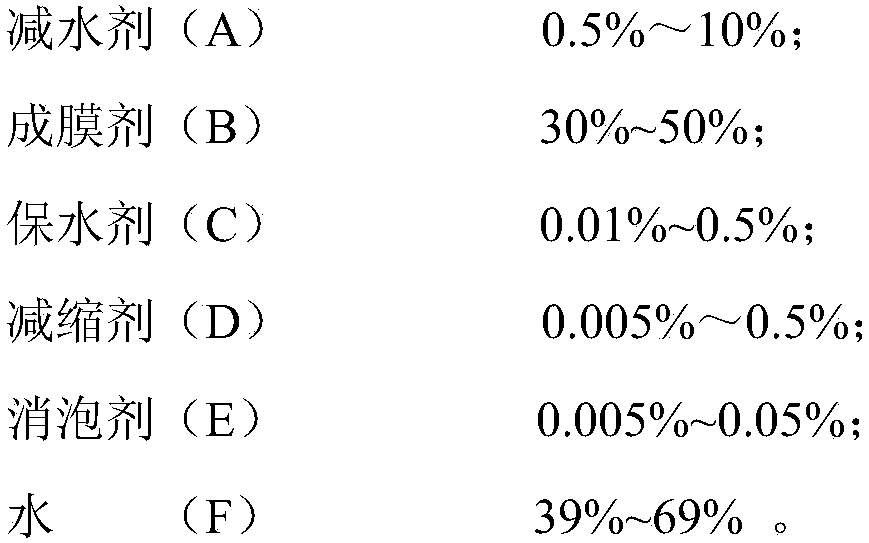

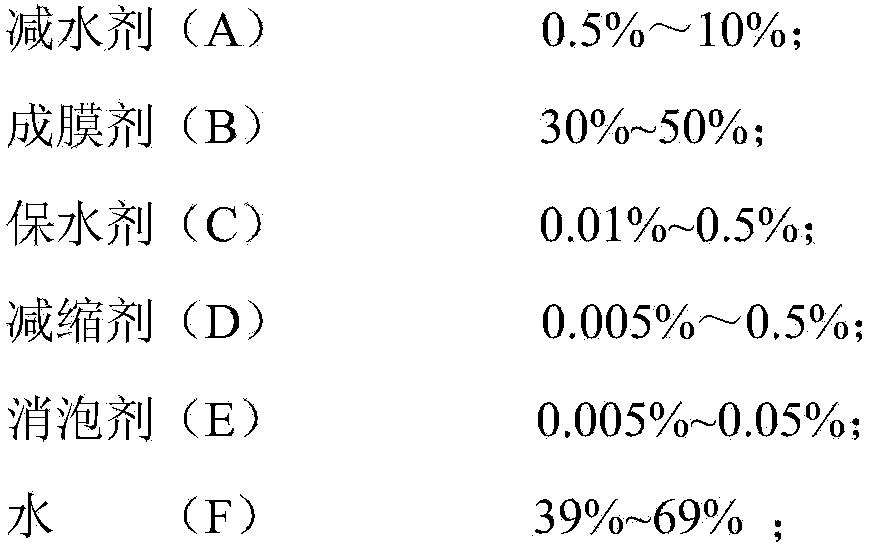

[0024] The special mortar compacting agent suitable for improving the durability of PCCP protective layer mortar in this embodiment, the weight components are: polycarboxylate high-performance water reducer: 2%; vinyl acetate-ethylene-acrylate copolymer: 38% Sodium carboxymethyl cellulose: 0.2%; Polyoxyethylenes: 0.05%; Ethylenediamine distearate: 0.005%; Water: 59.745%, the above-mentioned components are accurately weighed by weight percentage, according to the implementation The process described in Example 6 made the present invention.

Embodiment 2

[0026] The special mortar compacting agent suitable for improving the durability of PCCP protective layer mortar in this embodiment, the weight components are: sulfamic acid series superplasticizer: 5%; styrene-butadiene copolymer: 35%; polypropylene Amide: 0.2%; Amino alcohols: 0.05%; Organosilicon compound: 0.005%; Water: 59.745%. The above-mentioned components are accurately weighed by weight percentage, and the present invention is obtained by the process described in Example 6.

Embodiment 3

[0028] The special mortar compacting agent suitable for improving the durability of PCCP protective layer mortar in this embodiment, the weight components are: naphthalene series superplasticizer: 10%; vinyl acetate-ethylene-acrylate copolymer: 40%; polyethylene Alcohol: 0.3%; Ethanol: 0.1%; Organosilicon compound: 0.005%; Water: 49.595%. The above-mentioned components are accurately weighed by weight percentage, and the present invention is obtained by the process described in Example 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com