High temperature resistant baffle door and manufacturing method thereof

A high-temperature-resistant, baffle door technology, applied in coatings, fire-resistant coatings, epoxy resin coatings, etc., can solve the problems of reduced heat insulation effect, easy collapse and sintering of holes, and failure to achieve high-temperature resistance effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

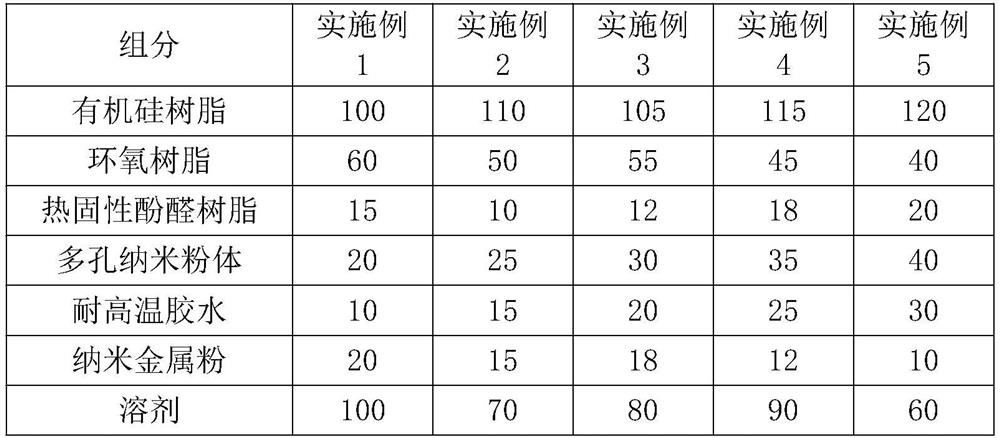

[0051] Example 1: A high-temperature-resistant baffle door, including a door body and a high-temperature-resistant coating coated on the surface of the door body. The components of the raw materials for the high-temperature-resistant coating and their corresponding parts by weight are shown in Table 1 , the pores of the porous nano-powder are loaded with silica airgel, the pore diameter of the porous nano-powder is larger than the particle size of the silica airgel, and the pore diameter of the porous nano-powder is in the range of 20-100nm. The particle size of silica airgel is below 15nm.

[0052] Among them, the porous nano-powder is nano-alumina, the nano-metal powder is nano-aluminum powder, the silicone resin is methylphenyl silicone resin, the epoxy resin is bisphenol A epoxy resin, and the high-temperature-resistant glue is purchased from Dongguan City. JL-812 980°C high-temperature repair agent from Juli Adhesive Products Co., Ltd., the solvent is xylene.

[0053] Th...

Embodiment 2-5

[0060] Embodiment 2-5: A high-temperature-resistant baffle door. The difference from Embodiment 1 is that the components of the high-temperature-resistant coating raw materials and their corresponding parts by weight are shown in Table 1.

Embodiment 6

[0061] Embodiment 6: A high-temperature-resistant baffle door, the difference from Embodiment 1 is that the method of porous nano-powder loading silica airgel is: dispersing porous nano-powder and silica airgel In water, ultrasonic treatment with a frequency of 12KHz and a power of 300W for 10 minutes, and drying at 100°C to obtain a porous nano-powder loaded with silica airgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com