Low thermal conductivity low density pyrolytic boron nitride material, method of making, and articles made therefrom

A thermal conductivity, boron nitride technology, used in chemical instruments and methods, polycrystalline material growth, metal material coating process, etc., can solve problems such as limiting thermal gradients, and achieve high thermal control and high anti-shedding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Eight standard density p-BN samples and 11 ultra-low density (ULD) p-BN samples produced according to the method described here were tested for density using a helium pycnometer. Samples were obtained by cutting small pieces of p-BN from a VGF crucible deposited on a graphite mandrel under the conditions described below. ULD p-BN was provided under the following reaction conditions: a temperature of 1750 °C, a pressure of 0.35 Torr, 2.4 liters per minute of BCl 3 Flow rates, ammonia flow rate of 6.5 liters per minute and nitrogen flow rate of 0.50 liters per minute.

[0030] Table 2

[0031] (Comparison of the density of standard density p-BN and ULD p-BN)

[0032]

[0033] variance

Embodiment 2

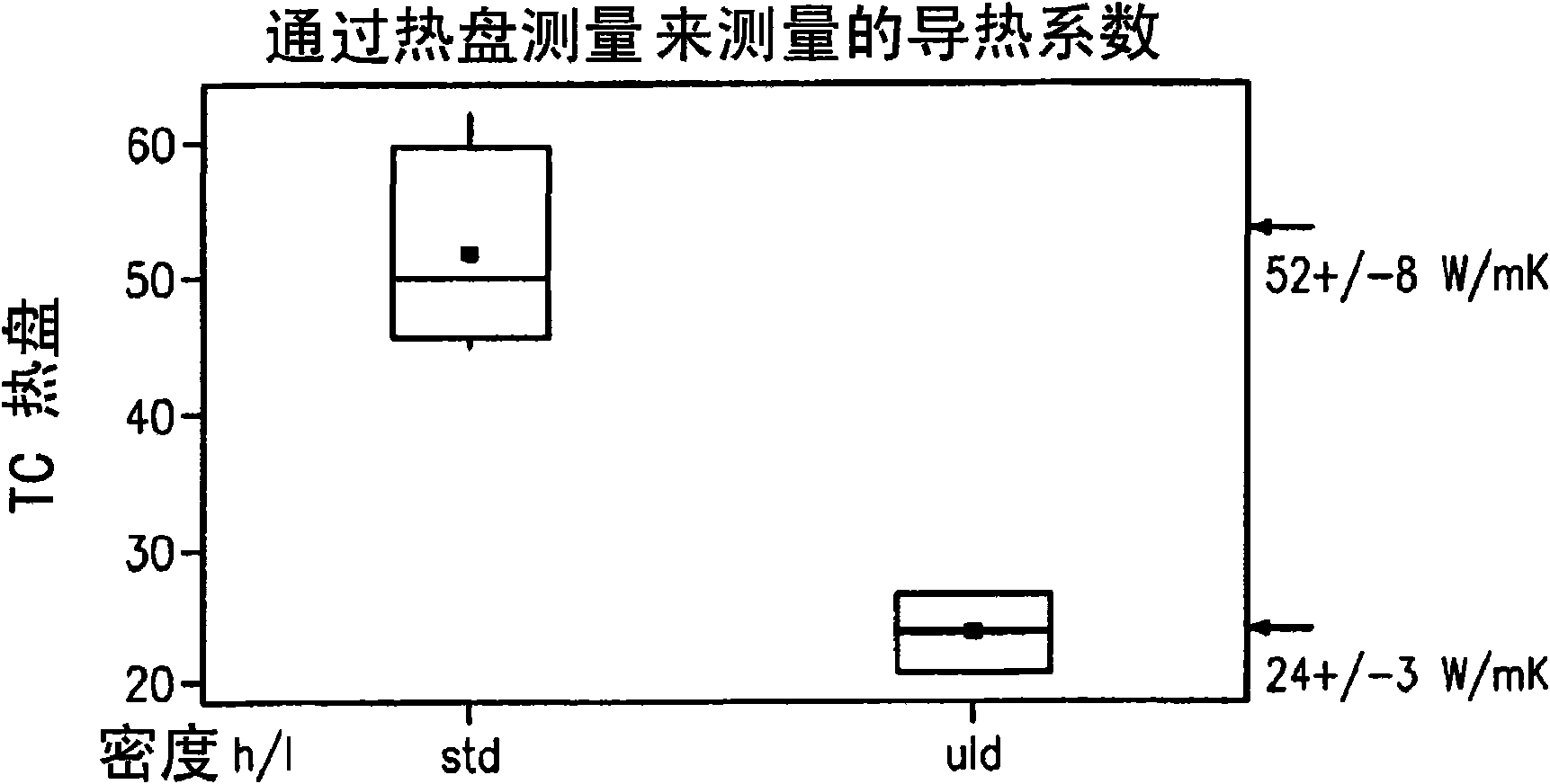

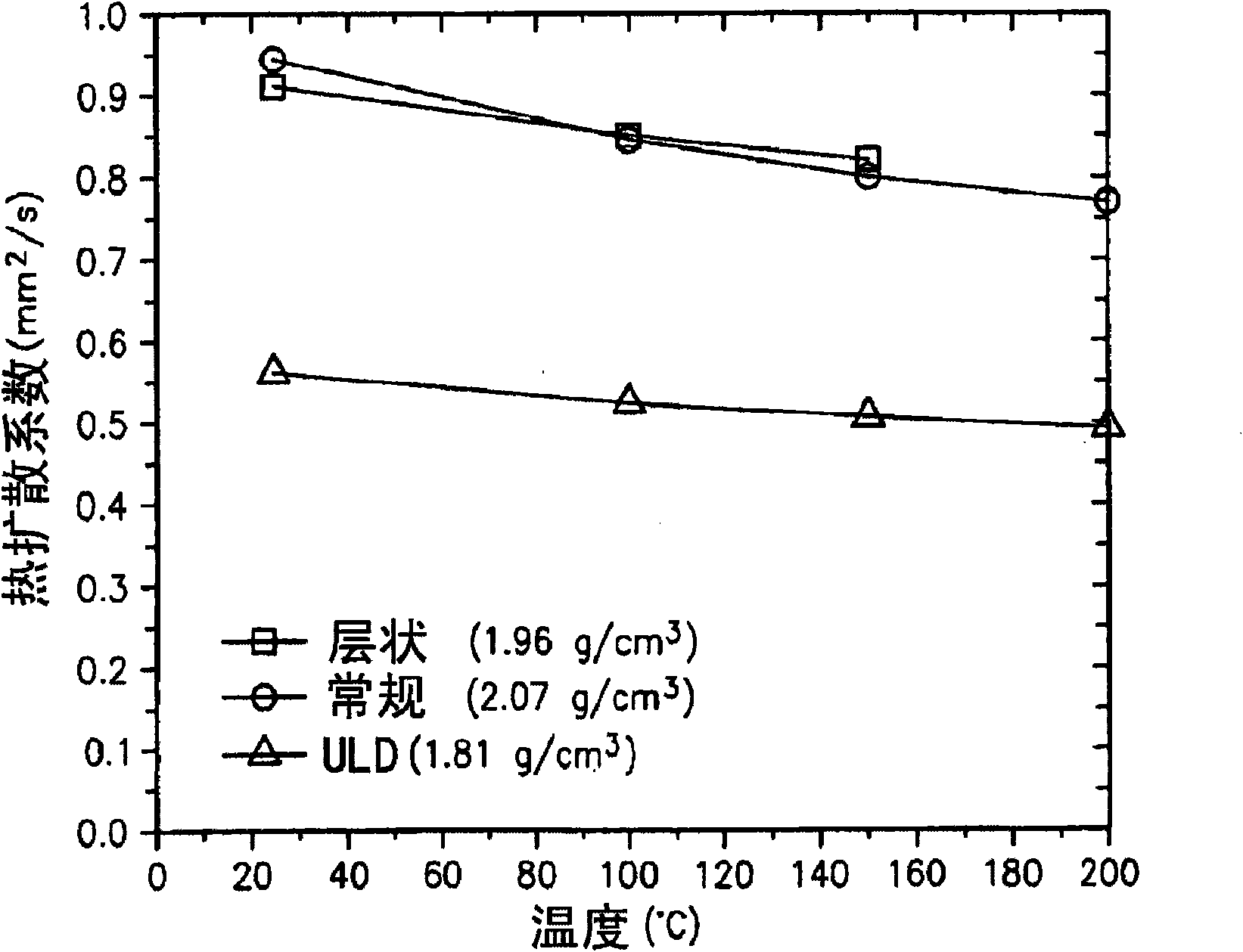

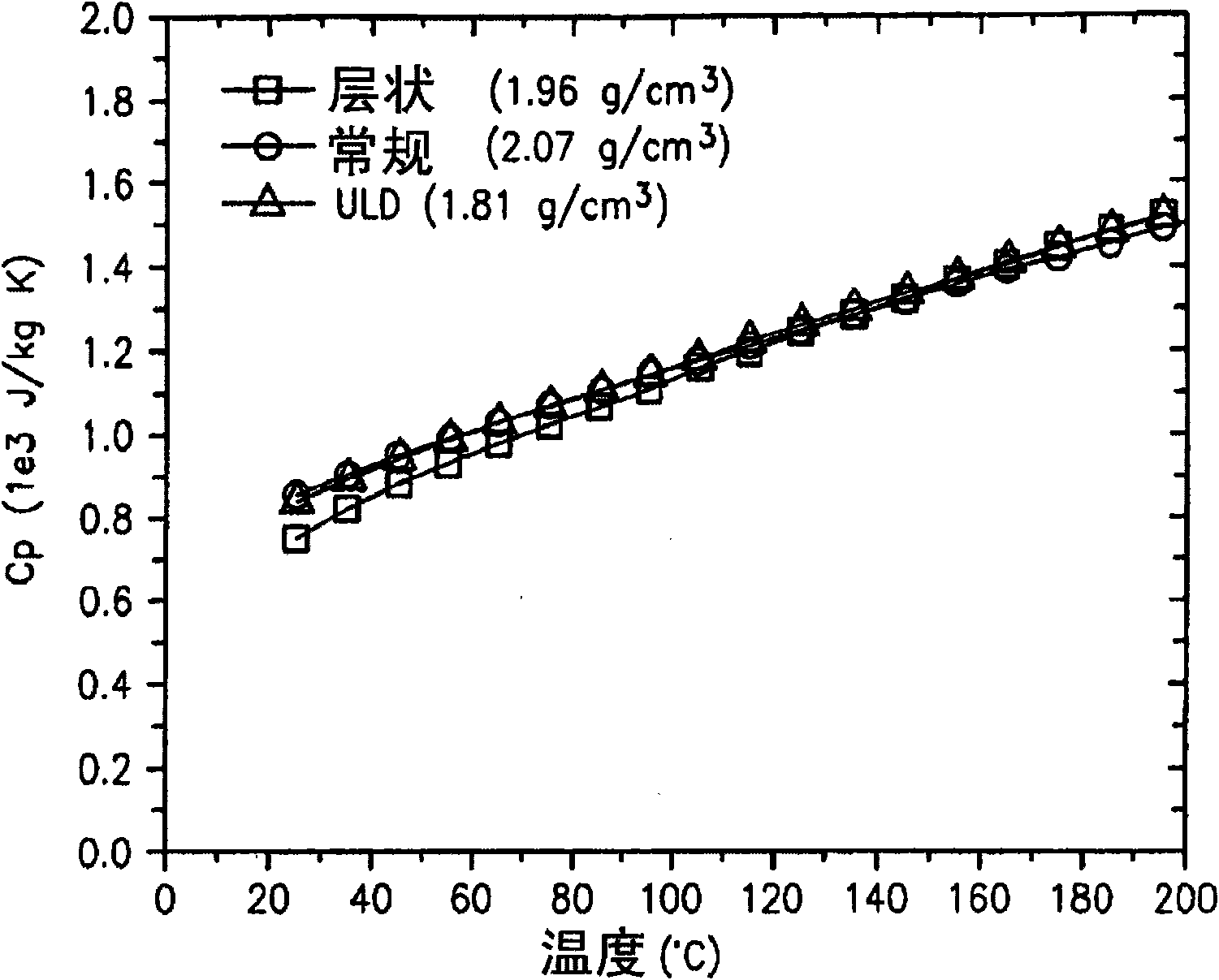

[0035] The thermal diffusivity and heat capacity of 8 samples of standard density conventional p-BN, layered p-BN and ULD p-BN of the present invention were measured. Samples were produced by CVD and cut from the top of the crucible. Layered p-BN is produced by pulsing dopant gases. Layered p-BN has higher density and different material properties (TC, mechanical strength, crystallinity, and orientation). Layering reduces shedding resistance. Measurements were performed by laser flash, diffusion coefficient and hot disc methods. The thermal conductivity is calculated according to the following formula.

[0036] α = k ρ · c p

[0037] in:

[0038] α is the thermal diffusivity,

[0039] k is the thermal conductivity,

[0040] ρ is the density, and

[0041] C p is the heat capacity

[0042] now refer to figure 2 , showing the through-surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com