LED-UV solvent-free spraying primer and method for coating thermosensitive substrates such as paper, solid wood and plastic with LED-UV solvent-free spraying primer

A primer, solvent-free technology, applied in primers, devices for coating liquid on the surface, coatings, etc., can solve problems such as cracking and peeling of the surface paint layer, and achieve improved adhesion and wet adhesion Concentrating on and improving the effect of anti-shedding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

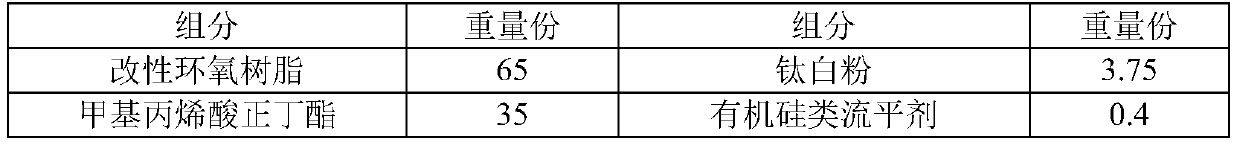

[0041] Example 1 is an LED-UV solvent-free spraying primer and its method for coating heat-sensitive substrates such as paper, solid wood, plastics, etc. disclosed by the present invention. The primer includes the following components in parts by weight:

[0042] Component Parts by weightComponent Parts by weight Modified epoxy resin65 Titanium Dioxide3.75 N-butyl methacrylate35 Silicone leveling agent0.4 Triphenyl silicon o-nitrobenzyl ether3.5 Polyacrylate0.3 diatomite6.25 Alkylsiloxane0.3

[0043] Modified epoxy resin is composite fiber / phenolic / epoxy resin;

[0044] The composite fiber is a compound of ramie fiber and carbon fiber with a mass fraction ratio of 1:0.55;

[0045] The preparation method of LED-UV solvent-free spray primer is:

[0046] A1. Preparation of composite fiber: ramie bone and carbon fiber are respectively dried and coarsely ground and finely ground into powder, and then the two are pulverized into nano-sized powder in a nano-pulverizer; then nano-sized ...

Embodiment 2

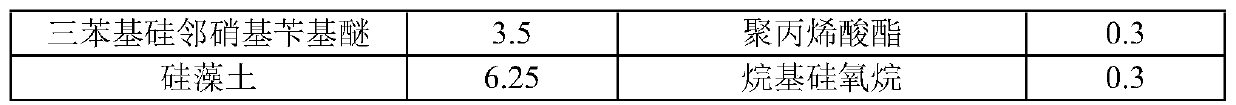

[0060] Embodiment 2 is an LED-UV solvent-free spraying primer and its method for coating heat-sensitive substrates such as paper, solid wood, plastics, etc. disclosed by the present invention. The primer includes the following components in parts by weight:

[0061] Component Parts by weightComponent Parts by weight Modified epoxy resin55 Titanium Dioxide1.875 N-butyl methacrylate30 Silicone leveling agent0.2 Triphenyl silicon o-nitrobenzyl ether2 Polyacrylate0.1 diatomite3.125 Alkylsiloxane0.1

[0062] Modified epoxy resin is composite fiber / phenolic / epoxy resin;

[0063] The composite fiber is a compound of ramie fiber and carbon fiber with a mass fraction ratio of 1:0.55;

[0064] The preparation method of LED-UV solvent-free spray primer is:

[0065] A1. Preparation of composite fiber: ramie bone and carbon fiber are respectively dried and coarsely ground and finely ground into powder, and then the two are pulverized into nano-sized powder in a nano-pulverizer; then nano-siz...

Embodiment 3

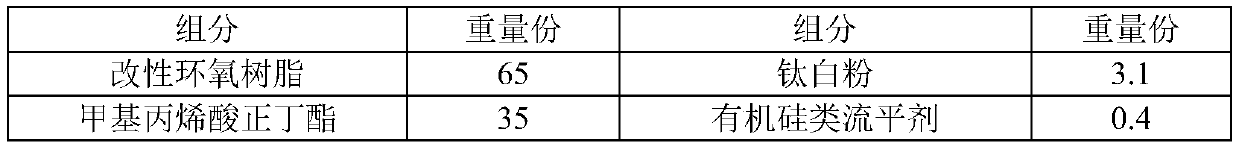

[0079] Embodiment 3 is an LED-UV solvent-free spray primer and its method for coating heat-sensitive substrates such as paper, solid wood, plastics, etc. disclosed by the present invention. The primer includes the following components in parts by weight:

[0080] Component Parts by weightComponent Parts by weight Modified epoxy resin75 Titanium Dioxide5.625 N-butyl methacrylate40 Silicone leveling agent0.6 Triphenyl silicon o-nitrobenzyl ether5 Polyacrylate0.5 diatomite9.375 Alkylsiloxane0.5

[0081] Modified epoxy resin is composite fiber / phenolic / epoxy resin;

[0082] The composite fiber is a compound of ramie fiber and carbon fiber with a mass fraction ratio of 1:0.55;

[0083] The preparation method of LED-UV solvent-free spray primer is:

[0084] A1. Preparation of composite fiber: ramie bone and carbon fiber are respectively dried and coarsely ground and finely ground into powder, and then the two are pulverized into nano-sized powder in a nano-pulverizer; then nano-sized ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com