Coating and production method thereof

A coating and hard technology, applied in the field of coating and its manufacturing, can solve the problems of inability to play an anti-oxidation effect, limitation, poor anti-oxidation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

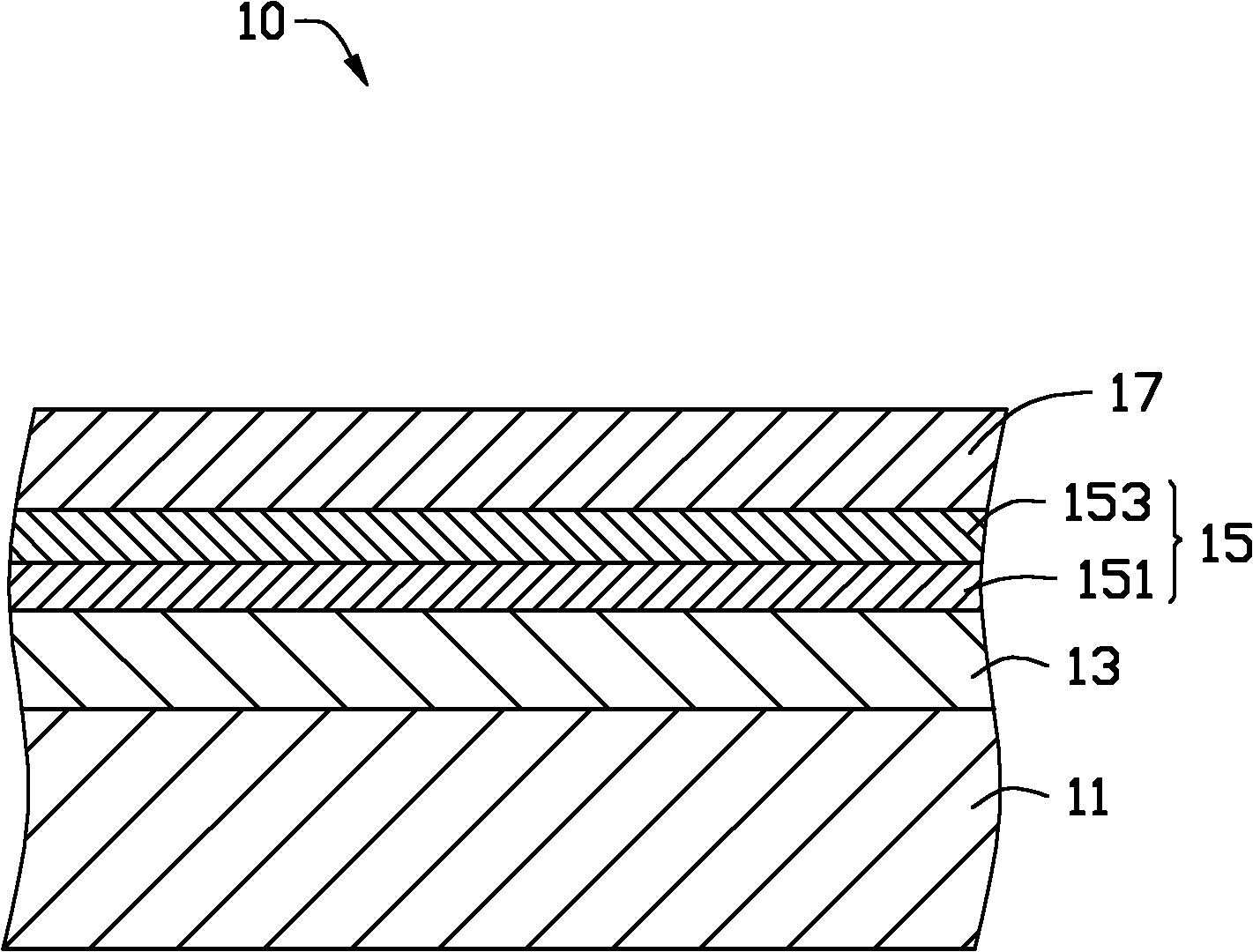

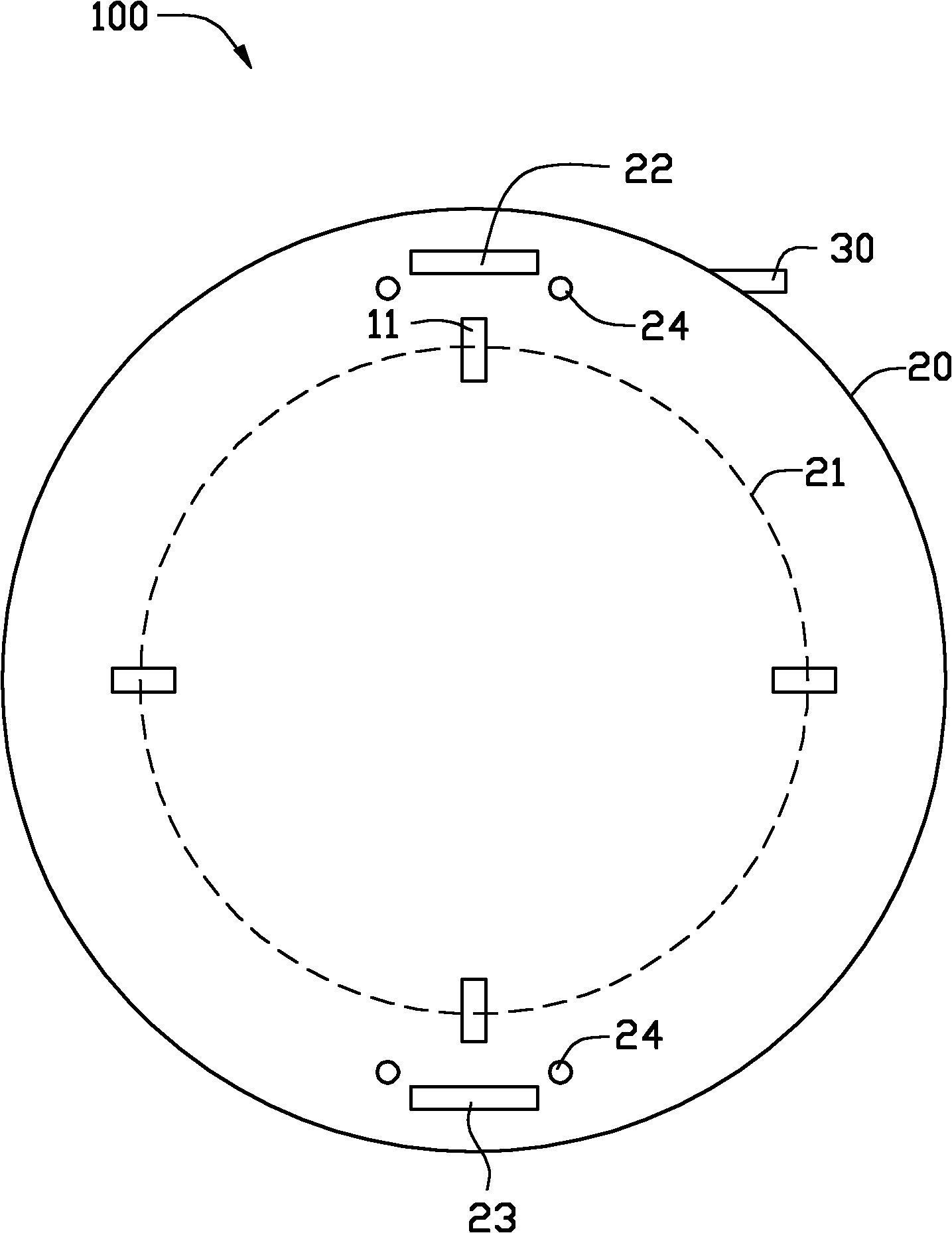

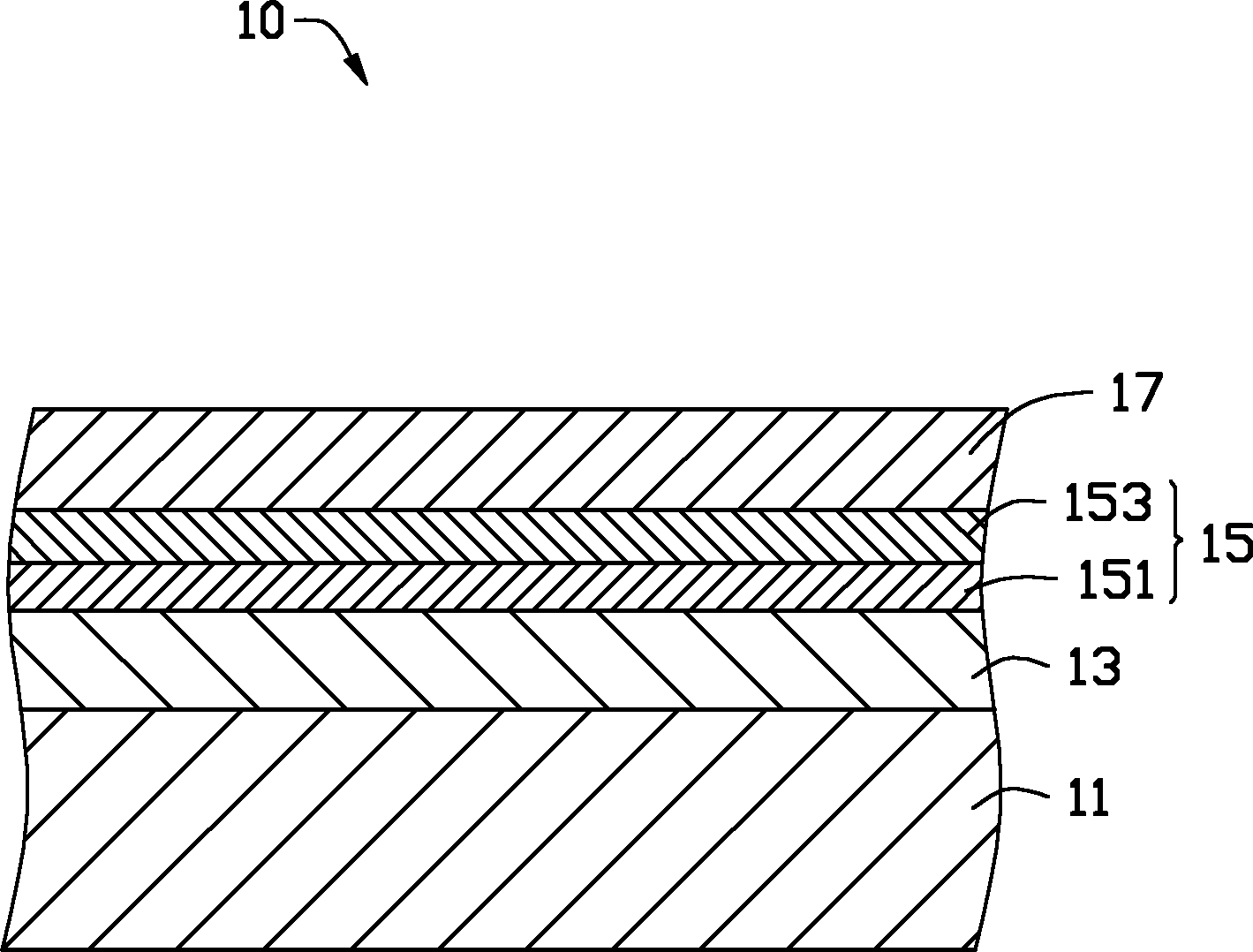

[0053] Plasma cleaning: the flow of argon gas is 280sccm, the bias voltage of the hard substrate 11 is -300V, and the plasma cleaning time is 9 minutes;

[0054] Sputtering transition layer 13: 100 sccm of argon gas is introduced, a bias voltage of -50V is applied to the hard substrate 11, the chromium target 22 is turned on, the power is set to 8kw, and the deposition time is 10min.

[0055] Sputtering chromium nitride layer 151: argon gas 100sccm, nitrogen flow rate is 10sccm, chromium target 22 is turned on, the power is set to 1kw, the bias voltage applied to the hard substrate 11 is -100V, and the deposition is 20 minutes;

[0056] Sputtering the hafnium nitride layer 153: argon gas 100 sccm, nitrogen flow rate 10 sccm, the hafnium target 23 is turned on and a bias voltage of -100V is applied to the hard substrate 11 for 60 minutes of deposition.

[0057] Sputtering anti-oxidation layer 17: Use argon as the working gas with a flow rate of 150 sccm, use oxygen as a reaction gas, se...

Embodiment 2

[0059] Plasma cleaning: the flow of argon gas is 280sccm, the bias voltage of the hard substrate 11 is -300V, and the plasma cleaning time is 9 minutes;

[0060] Sputtering transition layer 13: 100 sccm of argon gas is introduced, a bias voltage of -100V is applied to the hard substrate 11, the chromium target 22 is turned on, the power is set to 10kw, and the deposition time is 20min.

[0061] Sputtering the chromium nitride layer 151: pass argon gas 100 sccm, nitrogen flow rate 40 sccm, turn on the chromium target 22, set its power to 2kw, set the bias voltage of the hard substrate 11 to -150V, and deposit for 25 minutes;

[0062] Sputtering the hafnium nitride layer 153: argon gas 100 sccm was introduced, nitrogen gas 40 sccm was set, the hafnium target 23 was turned on and a bias voltage of -200 V was applied to the hard substrate 11 for 70 minutes of deposition.

[0063] Anti-oxidation layer 17: Use argon as the working gas with a flow rate of 150 sccm, use oxygen as the reaction ...

Embodiment 3

[0065] Plasma cleaning: the flow of argon gas is 280sccm, the bias voltage of the hard substrate 11 is -300V, and the plasma cleaning time is 9 minutes;

[0066] Sputtering transition layer 13: 100 sccm of argon gas is introduced, a bias voltage of -100V is applied to the hard substrate 11, the chromium target 22 is turned on, the power is set to 13kw, and the deposition time is 30min.

[0067] Sputtering chromium nitride layer 151: argon gas 100sccm, nitrogen flow rate 70sccm, chromium target 22 is turned on, the power is set to 3kw, the bias voltage of the hard substrate 11 is set to -300V, and the deposition is 30 minutes;

[0068] Sputtering the hafnium nitride layer 153: argon gas 100 sccm, nitrogen flow rate 70 sccm, the hafnium target 23 is turned on to apply a -300V bias on the hard substrate 11, and the deposition is 90 minutes.

[0069] Anti-oxidation layer 17: Use argon as the working gas with a flow rate of 150 sccm, use oxygen as the reaction gas, set the flow rate of oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com